-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

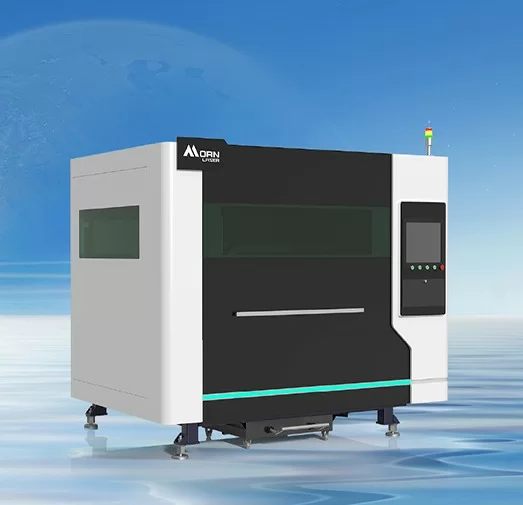

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

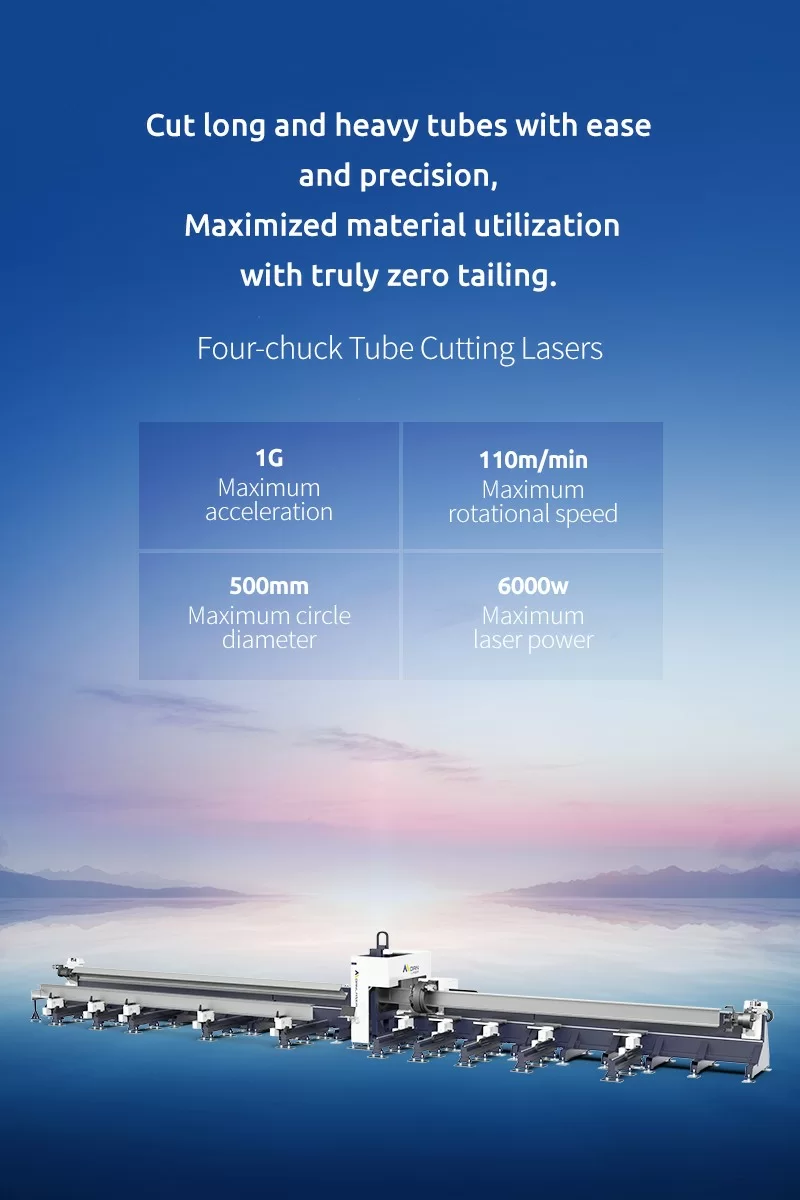

Cut long and heavy tubes with ease and precision, Maximized material utilization with truly zero tailing.

Four-chuck Tube Cutting Lasers

1GMaximum acceleration110m/minMaximum rotational speed500mmMaximum circle diameter12000wMaximum laser power![Four-chuck Tube Cutting Lasers]() Benefits you can get from our four-chuck tube laser cutting machine

Benefits you can get from our four-chuck tube laser cutting machine![]() Ease of use

Ease of use![]() Low cost per part

Low cost per part![]() Best-in-class performance

Best-in-class performance![]() Unsurpassed dynamics

Unsurpassed dynamics![Video Thumbnail]()

![YouTube Logo]()

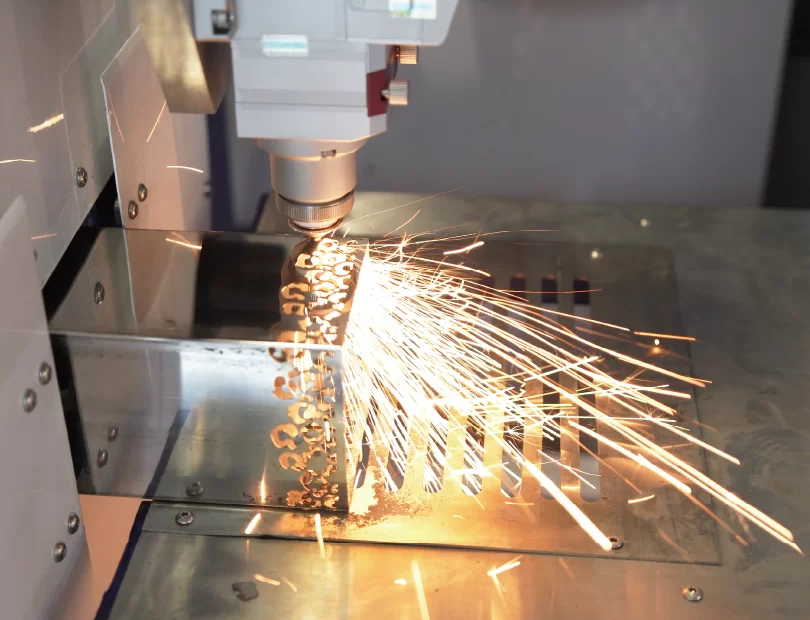

The head brings highest cutting quality and productivity. Lightweight design stands out with fast acceleration performance and cutting speed

The fully automatic feeding system intelligently lifts, sorts and instantly feeds the entire bundle of tubes into the machine. Each tube takes only 15 seconds to load.

The four-chuck design enables bidirectional pipe feeding and flexible clamping, maximizing material utilization. high processing efficiency, and low workpiece costs

Intelligent Cutting HeadAutomatic Loading SystemZero Waste CuttingApplication & cutting samples

Favored by metal sheet fabrication factories, automation lines and large fabrication stations, this metal tube laser cutting machine can accurately cut various complex shapes on metal pipes such as carbon steel, stainless steel, and aluminum.

Technical Data

Technical DataModel L123+6 Pipe Diameter φ20mm-160mm/ 200mm/350mm/500mm Pipe Length 3m-15m Laser Power 3000W/4000W/6000W/12000W Max. Chuck Rotating Speed 110m/min Max. Acceleration Speed 1 G You may also find these topics interesting

Cutting and then unloading takes up valuable time and effort, automate this process with Morn Laser’s exchange table sheet laser cutter and become more efficient! With just an immediate switch, you will keep your production line flowing with no stop.

Long and heavy tube cutting expert, truly zero-tailing. Make full use of your tube with this four-chuck tube laser cutting machine. Automatic bundle loader brings efficient production of big lots.

Fully enclosed integrated design, smaller footprint, safer and more reliable processing. The processing effect is more refined, and small workpieces can be precisely cut.

Cutting and then unloading takes up valuable time and effort, automate this process with Morn Laser’s exchange table sheet laser cutter and become more efficient! With just an immediate switch, you will keep your production line flowing with no stop.

Long and heavy tube cutting expert, truly zero-tailing. Make full use of your tube with this four-chuck tube laser cutting machine. Automatic bundle loader brings efficient production of big lots.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()