-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

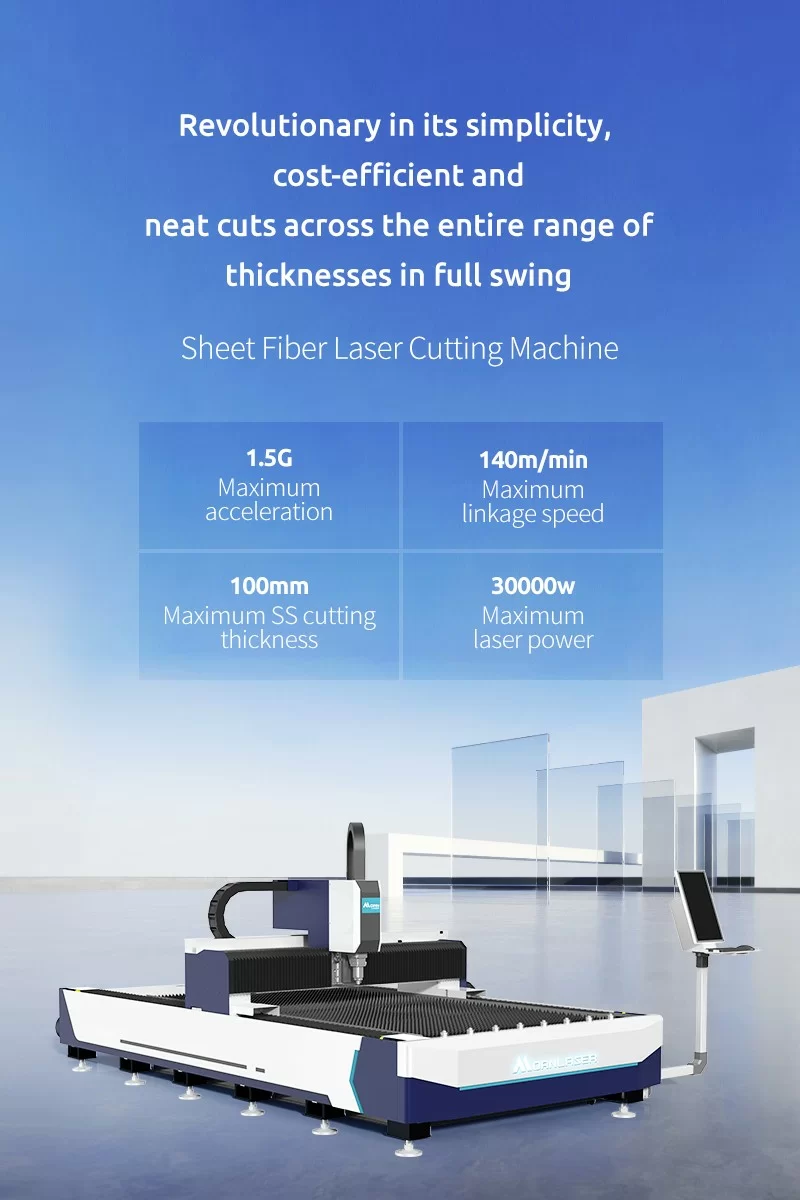

Revolutionary in its simplicity, cost-efficient and neat cuts across the entire range of thicknesses in full swing

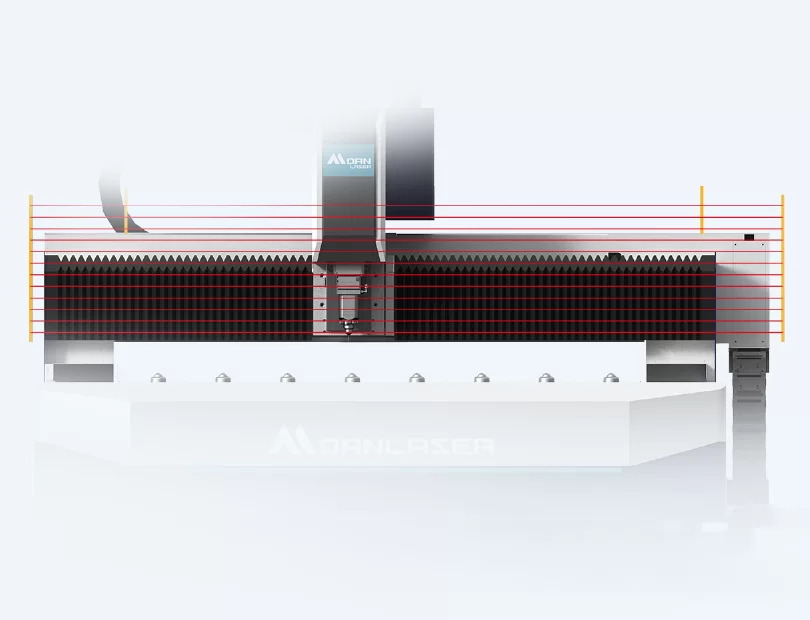

Sheet fiber laser cutting machine

1.5GMaximum acceleration140m/minMaximum linkage speed100mmMaximum SS cutting thickness30000wMaximum laser power![Sheet fiber laser cutting machine]() Benefits you can get from our Sheet Fiber Laser Cutting Machine

Benefits you can get from our Sheet Fiber Laser Cutting Machine![]() Robust and economical

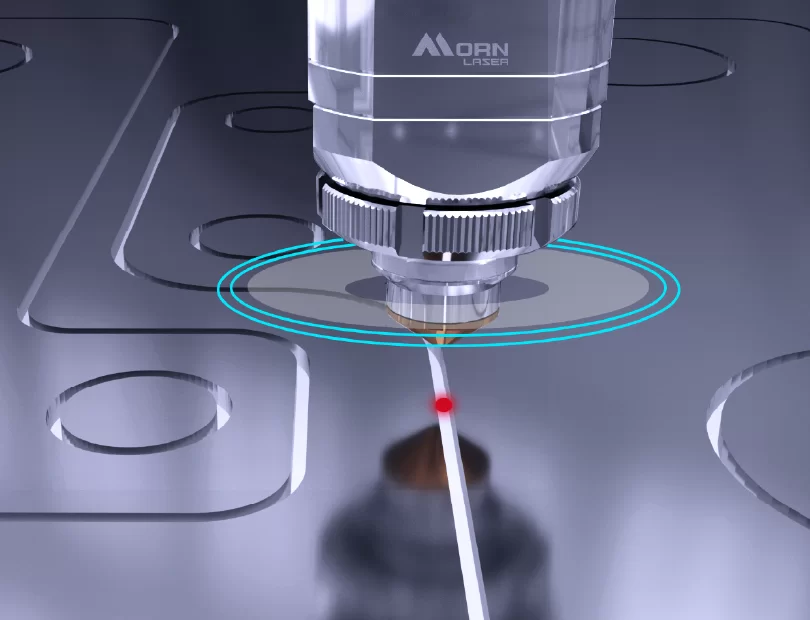

Robust and economical![]() Auto-focusing

Auto-focusing![]() Easy-to-learn

Easy-to-learn![]() Exceptional reliability and safety

Exceptional reliability and safety![Video Thumbnail]()

![YouTube Logo]()

Our auto-focus laser head cuts focusing time in half by automatically adjusting the focus to a suitable position.

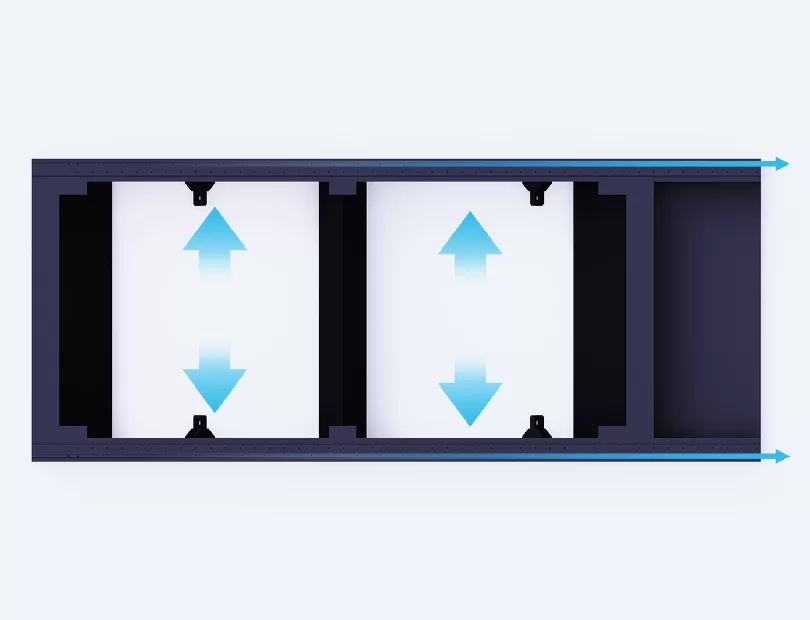

Each exhaust port can be independently controlled, with designated outlets for specific areas, ensuring optimal smoke removal.

Provides the highest level of safety protection for operators and equipment. When a person or object accidentally enters the danger zone, the machine automatically pauses operation.

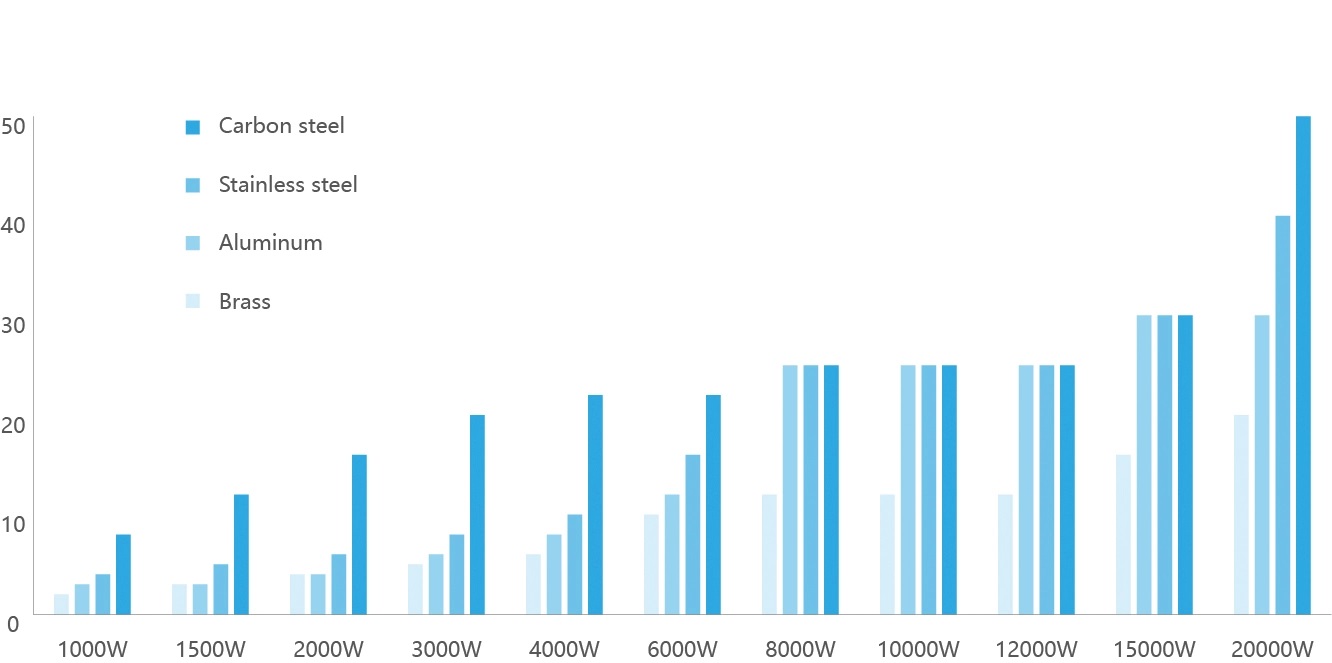

Auto Focus Laser HeadPartitioned Smoke ExhaustOptical GridTechnical Data Cutting ParametersModel FA3015 FA4020 FA6025 FA12020 FA12025 Working Area (Customizable) 3000*1500mm 4000*2000mm 6000*2500mm 12000*2000mm 12000*2500mm Laser Power 1000W/1500W/2000W/3000W/4000W/6000W/12000W/20000W/30000W/40000W/60000W Repeat Positioning Accuracy ±0.02mm Maximum Acceleration Speed 1.5G Power Supply AC380V 50HZ AC220V 60HZ

You may also find these topics interesting

With an integrated design, no disassembly is needed for delivery, and it can be directly put into a container, saving shipping cost.

Long and heavy tube cutting expert, truly zero-tailing. Make full use of your tube with this four-chuck tube laser cutting machine. Automatic bundle loader brings efficient production of big lots.

The metal laser cutting equipment can directly process metal coils, realizing an integrated production line of uncoiling, leveling, feeding, cutting and unloading during the production process.

With an integrated design, no disassembly is needed for delivery, and it can be directly put into a container, saving shipping cost.

Long and heavy tube cutting expert, truly zero-tailing. Make full use of your tube with this four-chuck tube laser cutting machine. Automatic bundle loader brings efficient production of big lots.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()