-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Increase joint welding efficiency and productivity with no further additional treatment

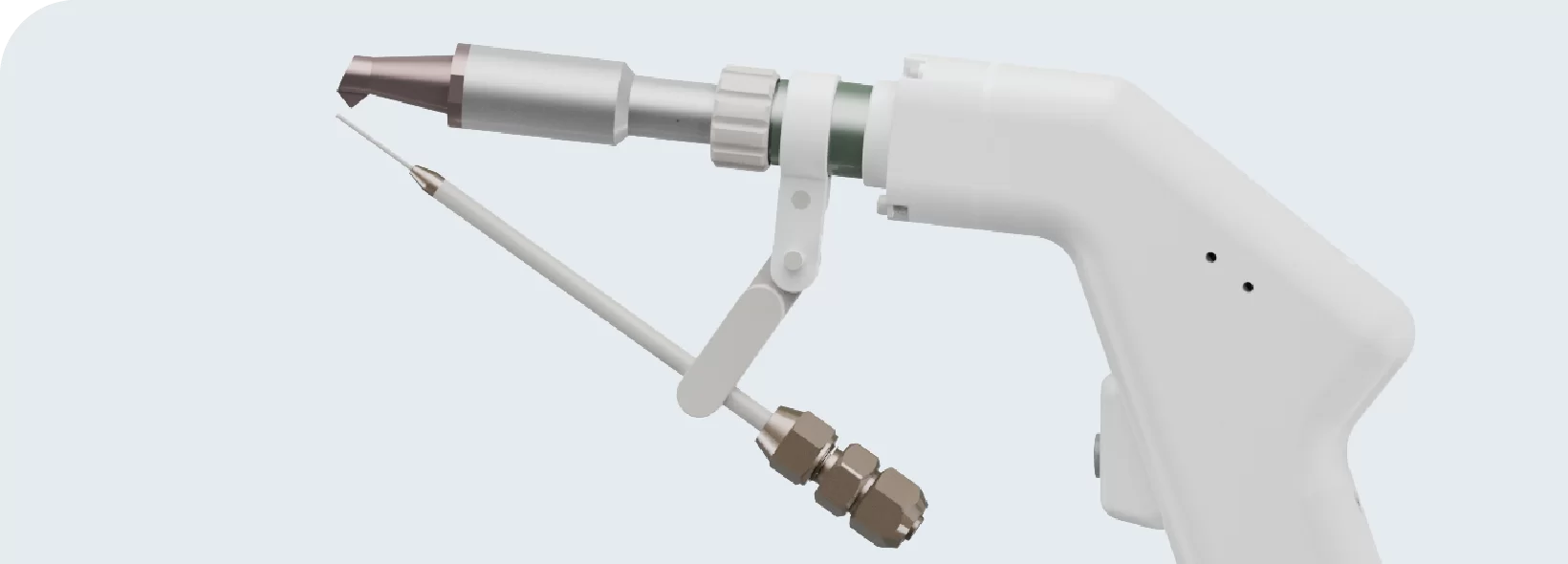

Handheld fiber laser welding machine

4X-fasterWelding speed10mmMaximum melting width6mmMaximum melting depth (double-side)2000wMaximum laser power![Handheld fiber laser welding machine]() Benefits you can get from our handheld fiber laser welding machine

Benefits you can get from our handheld fiber laser welding machine![]() Super welding strength

Super welding strength![]() Ultra-high welding strength

Ultra-high welding strength![]() Easy to learn and safe to operate

Easy to learn and safe to operate![]() Reduced labor and welding costs

Reduced labor and welding costs![Video Thumbnail]()

![YouTube Logo]()

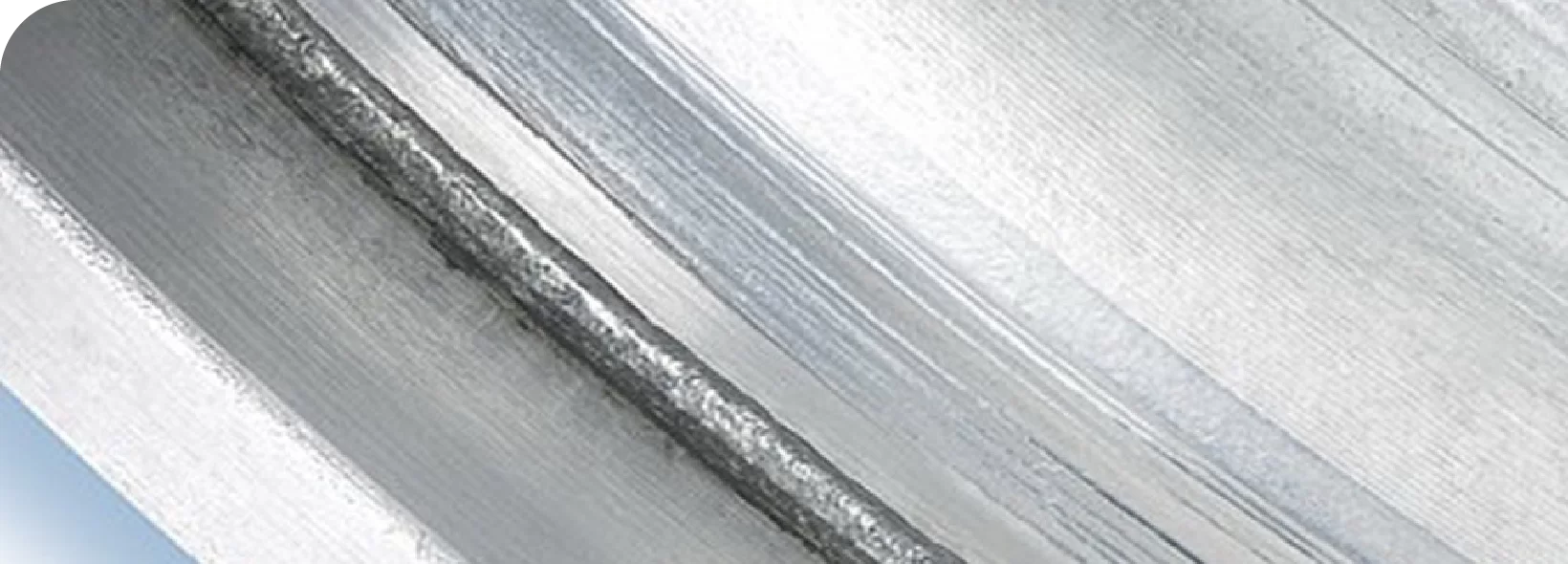

Up to 4-10 times faster than traditional welding methods, and the weld is fine and beautiful, with no need for secondary grinding. great! improving production efficiency.

Our handheld laser welder requires no senior technician, even a green hand could get started with laser welding in a few hours. It’s a good choice for curb labor expenses.

Set with movable pulleys, you could overcome the limits of fixed workstation and freely move your welding station to wide working environment scenarios. Custom fiber allows you to weld large objects and hard-to-reach places.

High Welding EfficiencyMulti-Welding ModesLong Distance WeldingTechnical Data Welding parametersModel MT-W1000 MT-W1500 MT-W2000 MT-W3000 Laser Power 1000W/1500W/2000W Output power tunability(%) 10-100% Laser head Handheld Type Laser wavelength 1080±5nm Spot size φ0.1-5mm Welding depth 1-3mm Material Thickness Single Side Weld Thickness Double Side Weld Stainless Steel Up to 5mm Up to 10mm Galvanized Steel Up to 5mm Up to 5mm Mild Steel Up to 5mm Up to 5mm Copper Up to 1mm Up to 2mm You may also find these topics interesting

Adopting active air-conditioning direct cooling technology, no need water chiller. Low failure rate of the whole machine, maintenance-free. The miniaturized design makes the laser welder smaller and lighter, easy to carry and move.

This welder empowers you to create permanent joints with toughness equivalent to the parent material. You will be pleasantly surprised with its dramatically faster welding speed and super productivity. Master metalwork in just a few hours.

Need a powerful welding solution to solve your multi-welding challenges? Our auto laser welder not only amazes you with consistent fine welds, but capabilities to weld hard-to-reach welding areas. Boost your factory with this super tool!

Adopting active air-conditioning direct cooling technology, no need water chiller. Low failure rate of the whole machine, maintenance-free. The miniaturized design makes the laser welder smaller and lighter, easy to carry and move.

This welder empowers you to create permanent joints with toughness equivalent to the parent material. You will be pleasantly surprised with its dramatically faster welding speed and super productivity. Master metalwork in just a few hours.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()