-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

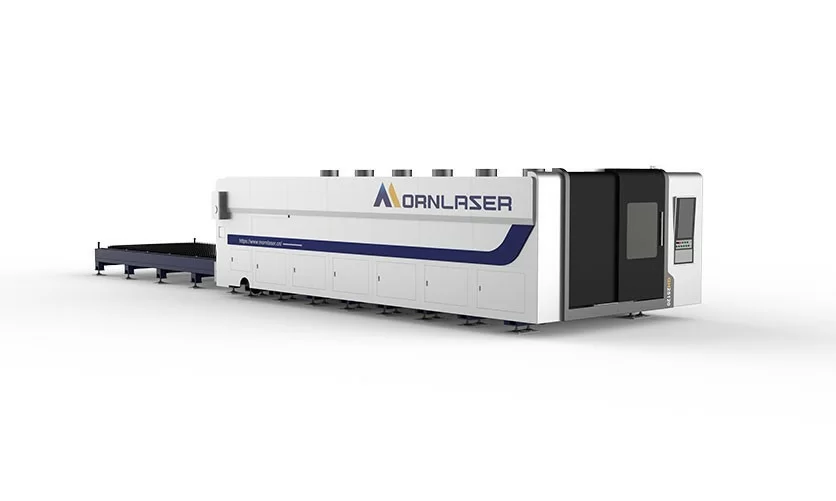

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

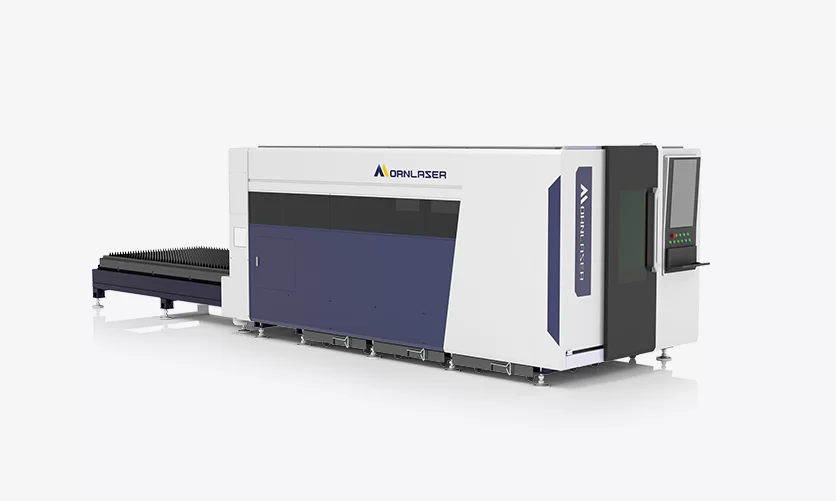

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

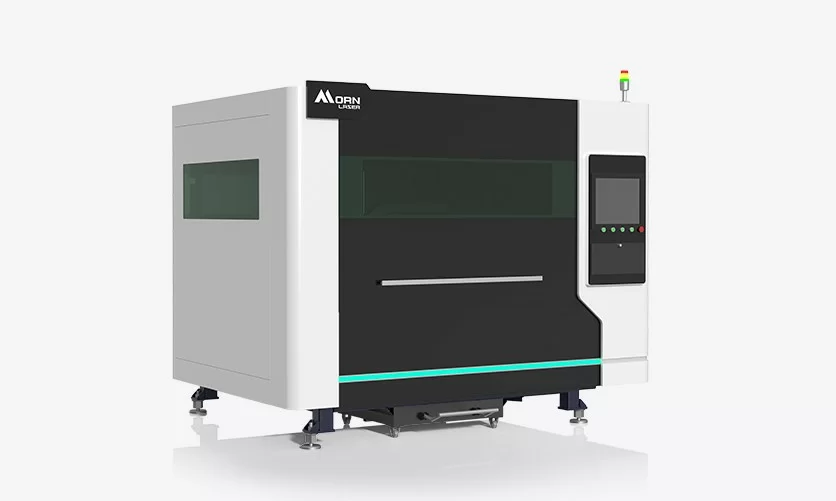

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

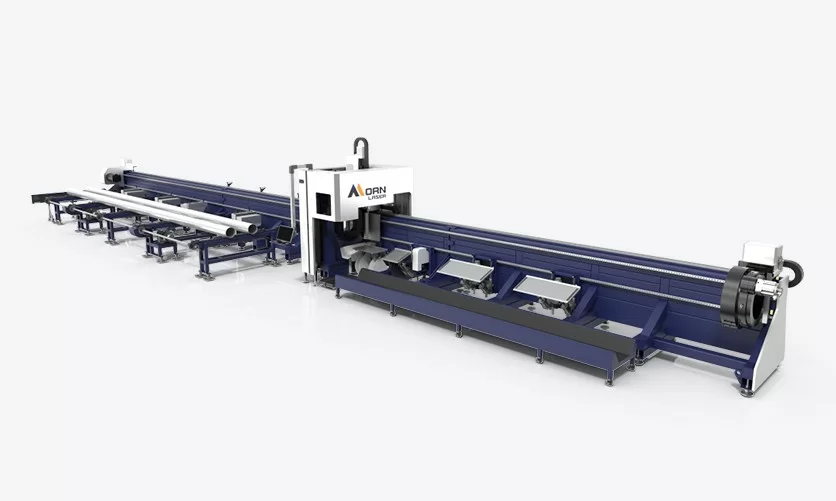

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Fiber laser cutting machines

build customers value with trustworthy products

The right laser cutting machine for all your needs: from fiber laser cutting machines with different powers and different processing sizes capable of processing thin to thick ferrous and non-ferrous materials, to laser tube cutting machines. Chat with a sales team member to learn about your application and specific needs. Finding the most satisfactory product for each customer is our top priority.

This laser cutting machine is specially designed for the steel structure industry and is suitable for cutting I-beams, H-beams, channel steels and other profile steels. It can be accurately connected to Tekla, reducing manual drawing time and improving production efficiency;

You will impress with top-notch laser cutting performance over the entire sheet thickness range, and double your production efficiency thanks to the auto loading system and dual pallet exchanger. Also a variety of intelligent functions and full cover provide you a safe and clean working environment.

Cutting and then unloading takes up valuable time and effort, automate this process with Morn Laser’s exchange table sheet laser cutter and become more efficient! With just an immediate switch, you will keep your production line flowing with no stop.

Want to get higher flexibility in metal sheet cutting. The newest laser bevel cutter streamlines your bevel cutting process and makes perfect bevels in one single shot. The produced precision parts are ideal for seamless welding.

Fully enclosed integrated design, smaller footprint, safer and more reliable processing. The processing effect is more refined, and small workpieces can be precisely cut.

Long and heavy tube cutting expert, truly zero-tailing. Make full use of your tube with this four-chuck tube laser cutting machine. Automatic bundle loader brings efficient production of big lots.

Three-chuck linkage cutting boosts your tube utilization with virtually no tailings. Three-position tube clamping plus follow-up supports ensure stable tube feeding and prevent long tubes from bending. As a result, you profit from high cutting precision, great efficiency and low material costs.

It can stably clamp round tubes, square tubes, I-beams, channel steels, special-shaped tubes, etc., to achieve efficient and stable cutting. It can be equipped with an automatic feeding system to achieve super-strong feeding and improve cutting efficiency.

With an integrated design, no disassembly is needed for delivery, and it can be directly put into a container, saving shipping cost.

The metal laser cutting equipment can directly process metal coils, realizing an integrated production line of uncoiling, leveling, feeding, cutting and unloading during the production process.

An automated three-dimensional storage tower enables the classification, retrieval, and management of various metals, significantly improving the feeding speed for laser cutting and the overall efficiency of the production line.

Change instantly from sheet to tube without the need for additional setup or tooling. Use your time making products instead of making changeovers. It’s the ideal way to maximize your return on investment.

You may also find these topics interesting

With decades of expertise, Morn Laser provided industrial approved laser tools to meet the needs of extensive applications across industries.

A resource center to introduce the latest industry happenings and inspirations. Dive deep with Morn Laser.

We are always pleased to support you in finding the best machine customized to your needs. Check out the pricing and discuss with us on how to get one-step closer to your success.

You may also find these topics interesting

![Application]()

Application

With decades of expertise, Morn Laser provided industrial approved laser tools to meet the needs of extensive applications across industries.

FIND OUT MORE![Morn Presents & Inspiration]()

Morn Presents & Inspiration

A resource center to introduce the latest industry happenings and inspirations. Dive deep with Morn Laser.

FIND OUT MORE![Pricing]()

Pricing

We are always pleased to support you in finding the best machine customized to your needs. Check out the pricing and discuss with us.

FIND OUT MORE- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()