-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Research and development

always improve and always deliver

As a one-stop industrial metal laser manufacturer in the field of laser cutting technology, Morn Laser strives to empower global metal fabricators with our smart and automatic metal laser solutions. Partnering with top Laser research centers and industrial partners, we keep challenging ourselves, producing even more efficient, precise, and future-proofing fiber laser products to our global customers.

Academic Partners![Laser-Institute-Shandong-Academy-of-Sciences]()

Laser Institute, Shandong Academy of Sciences

![Research-Center-for-Laser-Physics-and-Technology-of-Chinese-Academic-of-Science]()

Research Center for Laser Physics and Technology of Chinese Academic of Science

![San-Yat-sen-University-Laser-Research-Center]()

San Yat-sen University Laser Research Center

Industrial Laser partners

![mornlaser]()

![mornlaser]()

![IPG Photonics]()

![IPG Photonics]()

![Fuji Electric]()

![Fuji Electric]()

![Raycus]()

![Raycus]()

![maxphotonics]()

![maxphotonics]()

![Shanghai Bochu Electronics]()

![Shanghai Bochu Electronics]()

![PRECITEC]()

![PRECITEC]()

![GW LASER TECH]()

![GW LASER TECH]()

Metal Laser Patents

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

![Metal-Laser-Patents-1]()

Honors and Certificates

![High-technology-Enterprise-of]() High-technology Enterprise of Shandong Province

High-technology Enterprise of Shandong Province![Technology-and-Innovation]() Technology and Innovation enterprise of Shandong Province

Technology and Innovation enterprise of Shandong Province![Leading-Industrial-Enterprise]() Leading Industrial Enterprise of Shandong Province

Leading Industrial Enterprise of Shandong Province![Strategic-supported-Emerging]() Strategic-supported Emerging Enterprise of Shandong Province

Strategic-supported Emerging Enterprise of Shandong Province![Intelligent-Industrial-Laser]() Intelligent Industrial Laser Manufacture Pilot Project

Intelligent Industrial Laser Manufacture Pilot ProjectResearch and Development Timeline

Core Laser Technology

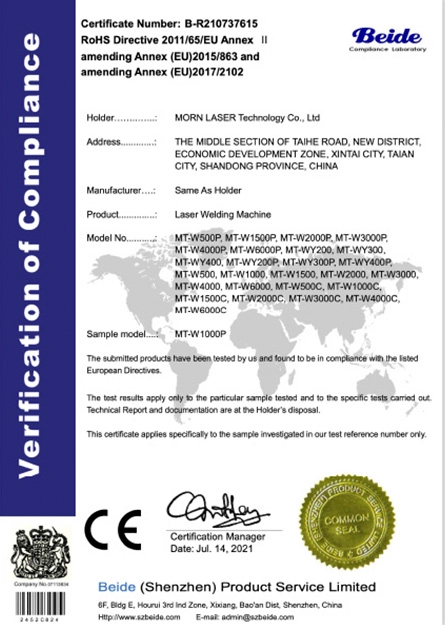

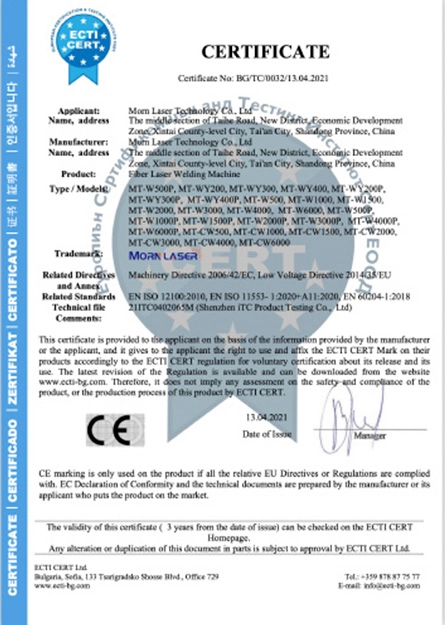

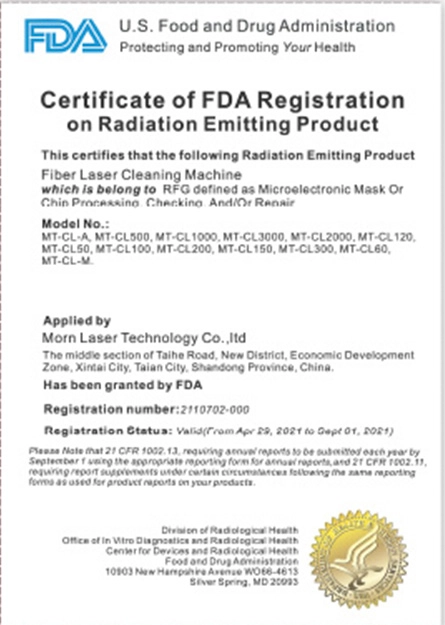

Innovative four chucks designAutomatic loading and unloading systemFully automatic from coiled steel feeding to cuttingAutomatic wire feeding technologySix-axis laser welding technologyCE and FDA Certified

![CE certificate]()

![CE certificate]()

![CE certificate]()

![CE certificate]()

![CE certificate]()

![CE certificate]()

![CE certificate]()

![CE certificate]()

![CE certificate]()

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()