-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

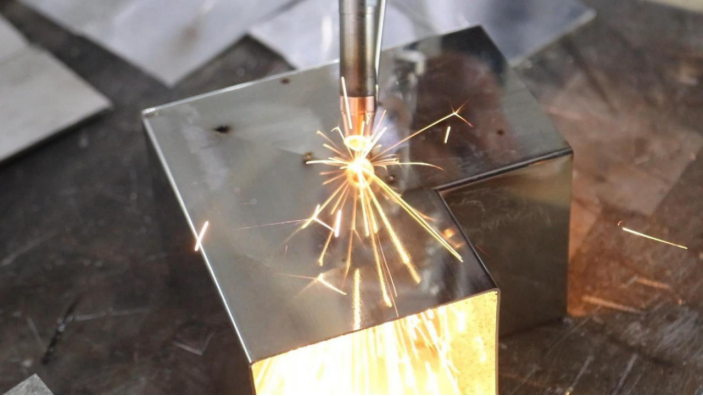

Handheld Laser Welding Machine: Enhancing Precision and Efficiency in Modern Manufacturing

2025-01-03In today’s highly competitive manufacturing landscape, businesses are continually seeking innovative ways to improve welding quality, reduce production time, and lower operational costs. The laser welding machine is emerging as a leading solution, offering high-precision welds, greater flexibility, and significant cost savings.

1. Unmatched Precision and Quality

One of the main advantages of the handheld laser welder is its ability to deliver high-quality welds with superior precision. With the laser technology, heat is concentrated directly at the welding site, minimizing the heat-affected zone and ensuring smoother, more uniform welds.

2. Improved Production Efficiency

In fast-paced manufacturing environments, production speed is crucial. The fiber laser welding machine greatly enhances welding efficiency, reducing the time spent on setup and adjustments. Unlike traditional welding, which often requires extensive pre-welding preparations, the laser welding system is ready for operation within minutes. This increased speed leads to shorter lead times and faster turnaround, enabling manufacturers to meet tight deadlines and maintain high production volumes.

3. Cost-Effectiveness and Material Savings

The handheld laser welding machine offers significant cost advantages, especially in terms of material efficiency. Traditional welding methods often result in material waste due to the large heat-affected zones and excessive filler material. In contrast, laser welding uses highly concentrated energy, allowing for precise application of heat, minimizing waste, and reducing the amount of filler material needed. This results in substantial cost savings on materials.

Moreover, the precision of the laser welding process reduces the need for rework, which further cuts down on labor costs. The minimal post-weld finishing required means fewer resources are spent on rectifying defects, enhancing overall profitability for manufacturers.

4. Flexibility for Small Batch and Custom Jobs

Another key benefit of the metal laser welding machine is its adaptability. It is particularly effective for small batch production and customized welding projects. Unlike traditional welding, which may require specific jigs or tools for each project, the laser welding is easily adjustable to accommodate different materials and welding styles without extensive reconfiguration.

This versatility makes it ideal for industries where production requirements frequently change, such as the automotive and electronics sectors. Whether welding intricate components or working with varying material thicknesses, the laser welding machine provides flexibility and consistency across a range of applications.

The handheld laser welding machine offers a compelling solution for businesses looking to improve welding precision, reduce production costs, and enhance overall manufacturing efficiency. With its cost-effectiveness, high-quality welds, and flexibility, it is well-suited for industries requiring high-volume or custom production runs. Whether you're in automotive, electronics, or other metal processing industry, investing in a handheld laser welding machine can significantly improve your production processes and provide a strong return on investment.

If you're interested in purchasing a metal laser welding machine or want to know the laser welding machine price, feel free to contact us anytime. We're here to assist you!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()