-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

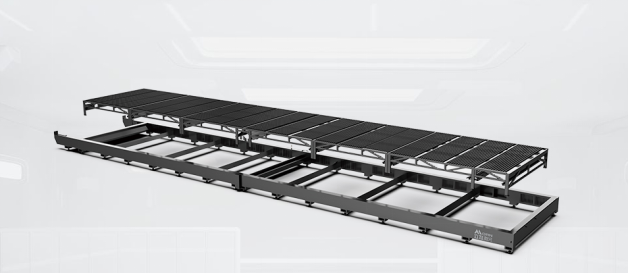

Breaking Traditional Limits: A Newly Designed Separated Working Bed with Both High Speed and Heavy Load Capacity

2025-03-05In the modern metal processing industry, achieving both high-speed cutting and strong working bed load capacity is often a challenge. Traditional high-power, large-format laser cutting machines typically adopt either a ground rail or gantry bed structure. Ground rail structures offer high load capacity but operate at lower speeds, while gantry beds enable faster movement but have limited load-bearing capability.

Addressing this industry pain point, we have introduced a newly designed separated working bed that innovatively combines the advantages of both structures. This design ensures stable load-bearing while significantly enhancing cutting speed, achieving the perfect balance between speed and strength.

Our newly designed bed features a dual inner and outer structure, breaking the limitations of traditional laser cutting machine beds that integrate load-bearing and motion. By optimizing the bed structure, we achieve a more scientific load distribution:

Inner Bed: Dedicated to supporting the weight of heavy metal plates, ensuring the machine can stably bear large metal materials and enhance processing stability.

Outer Bed: Designed to support only the weight of the beam, significantly reducing operational load. This allows for lighter and smoother beam movement, thereby enhancing cutting speed and accuracy.

This design achieves the separation of load-bearing and motion, enabling support for heavy metal plate cutting while ensuring the lightweight operation of the beam. As a result, it delivers faster cutting speeds and greater processing precision.

Our separated bed design perfectly balances high-speed processing with strong load-bearing capacity, providing a more efficient and cost-effective laser cutting solution for thicker and larger metal materials.

Choose Morn Laser to make your production more efficient and your investment more valuable! Contact us now to learn more about our laser products and discover a smarter, more economical metal processing solution for your business!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()