-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

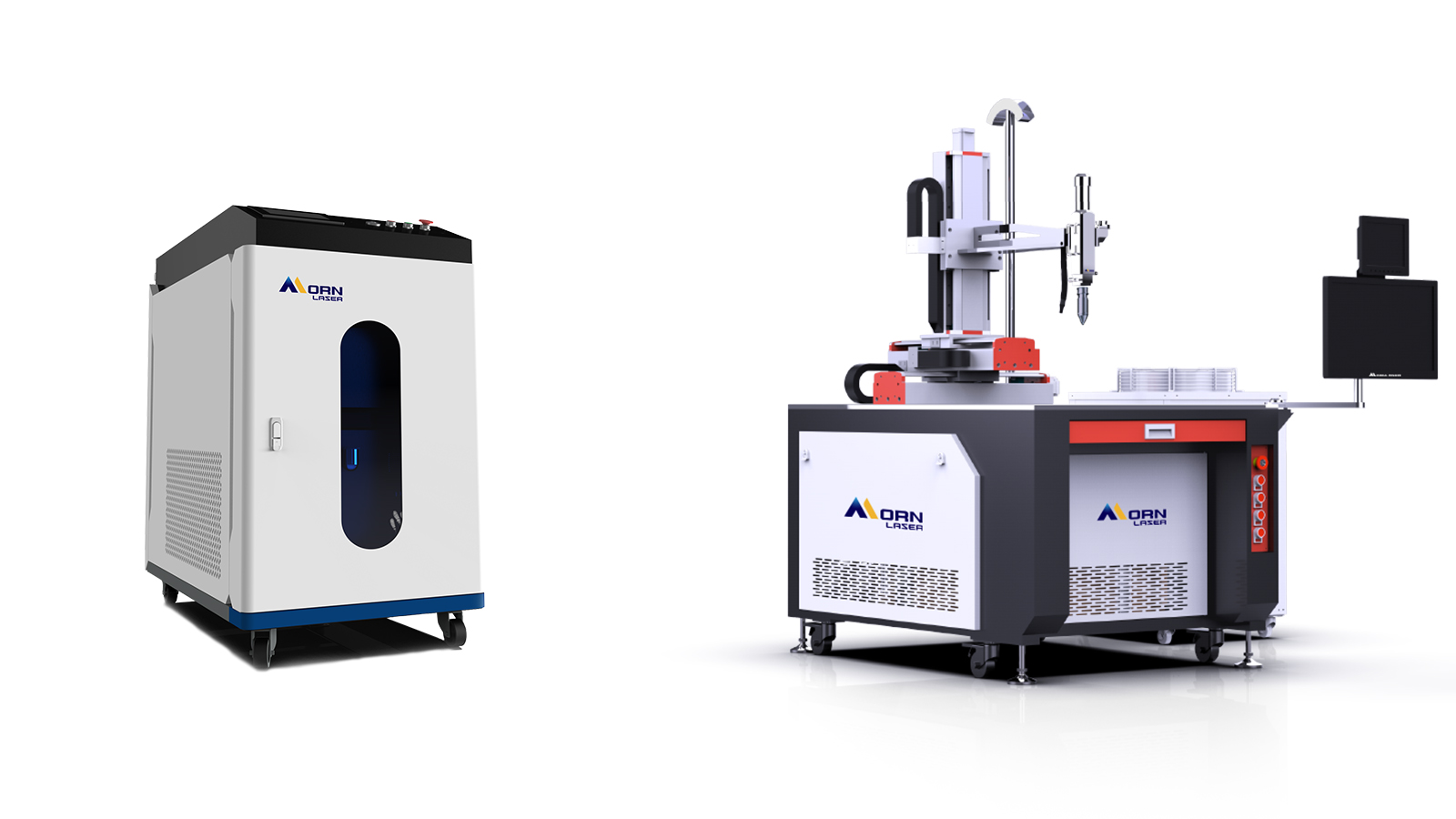

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Laser Welding Machines: Everything You Need to Know Before Buying

2025-06-30What Is a Laser Welding Machine?

A laser welding machine uses a concentrated beam of light to melt and join metal parts together. Compared to traditional welding methods like TIG or MIG, laser welding is faster, cleaner, and more precise. It creates strong, neat seams with minimal heat distortion—making it ideal for industries that demand speed and consistency.

Laser welding can be used on a wide range of materials including stainless steel, carbon steel, aluminum, brass, and galvanized metals.

Why Is Laser Welding Gaining Popularity?

In recent years, more manufacturers have switched to laser welding—and for good reason.

- First, it significantly reduces production time. Laser welders can operate up to four times faster than TIG welding, especially when working with thin or medium-thickness metals.

- Second, it delivers cleaner results. Since laser welding produces a smaller heat-affected zone, parts stay flat and require little to no grinding or polishing afterward.

- Third, it's surprisingly easy to learn. Unlike traditional welding, which requires experienced hands, most operators can learn to use a handheld laser welder within a few hours of training.

- Finally, the strength and appearance of the welds are excellent. The seams are deep, strong, and smooth—perfect for visible or high-stress applications.

Handheld, Platform, or Automated Type: What Are Your Options?

There are three main types of laser welding systems to consider.

Handheld laser welders are portable and flexible. They're perfect for workshops that need mobility or work on custom projects, stainless steel furniture, or field repairs.

Platform laser welding machines are built for mass production. With custom fixtures and automatic programming control, it enables fast and consistent batch welding of similar products.

Robotic laser welding machines are built for automation and mass production. These systems are usually installed on production lines where speed, repeatability, and minimal operator involvement are key.

Morn Laser offers these machines, with options ranging from 1000W to 6000W power, depending on your application.

Where Can You Use Laser Welding?

Laser welding is a great fit for industries like metal fabrication, furniture manufacturing, appliances, automotive parts, and even aerospace components. Whether you're welding stainless steel frames, aluminum enclosures, water tanks, or battery boxes, a fiber laser welder gives you speed and quality that older methods simply can't match.

How Does It Compare to Traditional Welding?

Laser welding outperforms conventional welding in many ways. It generates less heat, which means less warping and a cleaner finish. It's faster—sometimes several times faster—and usually doesn't need filler wire. Best of all, it doesn't demand years of welding experience to get great results.

That said, traditional methods still have their place in heavy-duty structural applications or for very thick materials. But for thin to medium-thickness metals, laser welding is often the better choice.

What About the Cost?

A basic 1000W–1500W handheld laser welder starts around $4,000 to $6,000. If you're looking for a fully automated or robotic solution, the investment may be more depending on the configuration.

Still, many users see a return on investment within 3 to 9 months—thanks to labor savings, improved productivity, and reduced rework.

What to Consider Before Buying?

Before you invest in a laser welding machine, think about the materials you'll be working with, the required weld depth, and whether portability or automation is more important for your workflow.

Why Choose Morn Laser?

Morn Laser has helped businesses in over 156 countries and regions modernize their process. Our fiber laser welding machines are stable, easy to operate, and built for industrial use. We provide comprehensive support—from choosing the right model to installation, training, and lifetime after-sales service.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()