-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Pricing

- Contact

Menu

X- home

-

Product >

-

Breaking the Limitations of Traditional Metal Straight Cutting - Morn Laser Bevel Laser Cutting Machine

2024-08-23With the development of industries such as shipbuilding, mining machinery and construction machinery, many components require beveled edges due to their design. Bevel processing is mainly done to prepare for the next welding process. By machining and assembling the workpieces into specific geometric shapes at the weld joint, the welded parts will merge more effectively. Therefore, choosing the right bevel cutting method is crucial for ensuring welding quality, improving production efficiency and reducing costs.

Traditional bevel cutting methods primarily include flame cutting, plasma cutting, shearing, grinding, milling, and planing, or using laser cutting followed by manual or other auxiliary bevel processes. Although these traditional methods have played a significant role in manufacturing for a long time, their limitations are becoming increasingly apparent with the transformation and upgrading of the manufacturing industry.

For example, flame and plasma cutting may produce excessively deep cuts that need to be removed before welding to avoid the problem with unfused bevels. Especially in areas with complex geometric shapes or difficult to access, grinding is the only way to eliminate them. This not only wastes labor but also greatly reduces production efficiency.

In addition, high-heat processing methods may also cause thermal deformation of metals, increasing the complexity of subsequent processes. Obvious cutting marks, significant thermal distortion, complex procedural steps and high labor costs, etc., all become shackles that restrict production efficiency and quality. These can neither meet the needs of large-scale bevel cutting nor guarantee the quality of subsequent welding. This is obviously unable to meet the needs of the rapid development of enterprises in today's pursuit of high efficiency, precision and low cost.

Therefore, Morn Laser launched the bevel laser cutting machine to achieve the two-way pursuit of metal bevel cutting efficiency and quality, reduce cumbersome processing procedures, greatly save time and cost, and solve the bevel processing problems for customers.

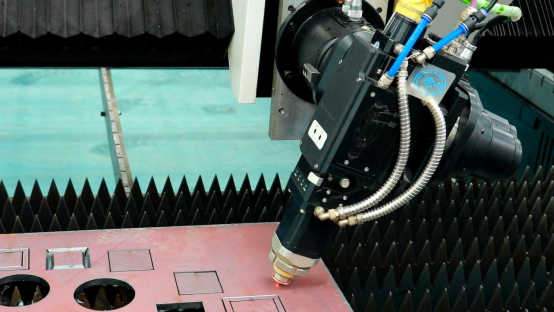

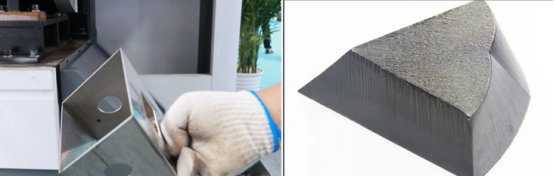

Morn Laser bevel laser cutting machine is equipped with three-dimensional five-axis cutting technology, breaking the traditional 0° straight cutting surface and achieving a maximum 45° bevel cutting. It can complete different types of bevels such as V-type, X-type, and Y-type, and form them in one go. At the same time, it uses branded laser source with good beam quality, small thermal deformation and beautiful cutting surfaces. It reduces the difficulty of welding, reduces the processing procedures, and further effectively improves the processing efficiency of medium and thick metal sheets.

Recommended machines:

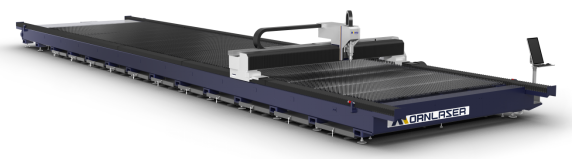

High-speed cutting of medium and thick plates, customizable processing format, one-step forming of bevel cutting.

Laser Power

2000W-60000W

Working Size

1500*3000mm-3100*14000mm (customizable)

Tube bevel laser cutting machine

Easily cut different metal pipes, 0-45° bevel cutting, automatic loading and unloading.

Laser Power

1000W-12000W

Cutting pipe length

6/9/12 (customizable)

Morn Laser will always be committed to the research and development and production of intelligent laser equipments, and continue to empower customers to reduce costs and increase efficiency!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]() 验证码

验证码