-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

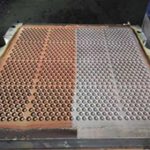

MORN Fiber Laser Cleaning Machine Advantages

2022-07-22Fiber laser cleaning machine is a more green and environmentally friendly cleaning method than traditional cleaning. Laser cleaning uses high-energy laser pulses to irradiate the surface of the workpiece to instantly evaporate or peel off oil, rust or coatings on the surface. It can effectively remove surface deposits or surface coatings at high speed.

Traditional cleaning methods, such as manual cleaning (low efficiency and ineffective, not all attachments can be removed); mechanical cleaning (wear and tear on the workpiece is irreversible); people’s awareness of environmental protection and safety is becoming more and more Strong, norm-compliant chemicals are becoming rarer. And for some large-scale equipment cleaning, if this method is used, the metal material substrate may be corroded. When Morn laser cleaning machine processes workpieces, it is only necessary to adjust the parameters of laser cleaning. So what is the main advantages of Morn laser cleaning machine? Please refer to the following details:

1. Higher efficiency

Under the action of high temperature energy, the deposits are instantly vaporized and evaporated off the surface of the object, and the time required is very short. The traditional cleaning methods, such as ultrasonic cleaning, it can only be cleaned after preheating, cooling and other processes, which takes a long time.

2. More environmentally friendly

Laser cleaning is a “green” cleaning method that does not require the use of any chemicals and cleaning fluids. The cleaned waste is basically powder, small in size, easy to store, recyclable, and has no chemical reaction. It can easily solve the problem of environmental pollution caused by chemical cleaning.

3. Lower cost

Laser cleaning is faster, more efficient, and saves time; although the initial one-time investment in purchasing a laser cleaning machine is high, the laser cleaning machine can be used stably for a long time, and the operating cost is low. More importantly, it can be easily automated.

laser cleaning - banner

Laser cleaning in a precise and environmentally friendly manner

4. More convenient

Laser cleaning can remove different types of contaminants on the surface of different materials, and achieve cleanliness that cannot be achieved by conventional cleaning. Moreover, contaminants on the surface of the material can be selectively cleaned without substantially damaging the surface of the material.

5. Better cleaning effect

The traditional cleaning method is often contact cleaning, which has a mechanical force on the surface of the cleaned object, causing damage to the surface of the object or unable to remove the medium attached to the surface of the object to be cleaned. The non-abrasive, non-contact, and non-thermal effects of laser cleaning will basically not damage the base metal.

6. More convenient control

The laser can be transmitted through the optical fiber, which can easily realize long-distance operation and can clean the parts that are difficult to reach by traditional methods. The laser cleaning machine can choose the corresponding pulse frequency, energy and wavelength according to the material to achieve better results

7. Higher security

Remote operation, no harmful substances and gases, better guarantee the safety of operators

Click on the machine photos to go directly to the machine details! if you don’t know which machine is more suitable, just write your demands, our sale engineer will choose the most suitable machine to you~

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()