-

Product

-

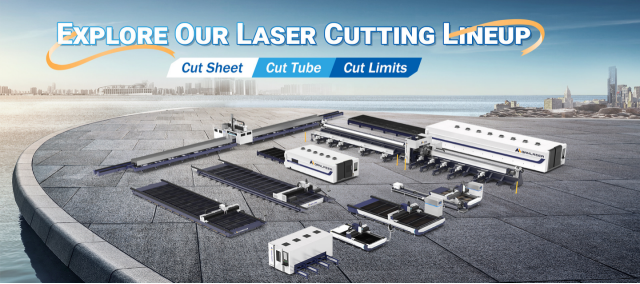

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Pricing

- Contact

Menu

X- home

-

Product >

-

Used Laser Cutting Machines: Opportunity or Risk? Hidden Costs You Shouldn't Ignore

2025-11-06At first glance, buying a used laser cutting machine may seem like a smart shortcut and an easy way to access high-end equipment at a fraction of the cost. However, behind the tempting price tag often lies a series of hidden risks, repair expenses, and long-term performance issues that can quietly eat away your savings.

Before making the decision, it's crucial to understand the true costs and evaluate whether a used machine really fits your production goals.

1. The Illusion of “Low Price”

The biggest attraction of second-hand laser cutting machines is their seemingly low purchase price. But what many buyers overlook is the total cost of ownership, which includes maintenance, replacement parts, and unexpected downtime.

Used fiber laser cutting machines may have worn components such as laser sources, cutting heads, or servo systems. Once out of warranty, replacing or repairing these parts can cost almost as much as buying a new unit.

What's worse, older machines often use outdated control systems that are incompatible with modern software, making upgrades difficult and expensive.

2. Declining Precision and Performance

Laser cutting is all about precision and stability. Even if a second-hand laser cutting machine appears well-maintained, it’s unlikely to match the cutting accuracy and speed of a new model, especially when handling reflective or thick materials like stainless steel or aluminum.

For manufacturers pursuing efficiency and quality, these micro-level deviations can translate into major production losses over time.

3. Hidden Maintenance Costs and Downtime

Unlike new machines backed by manufacturer support, second-hand units usually come with limited service and no official warranty.

If a key component such as the fiber laser source, cooling system, or control board fails, sourcing replacements can be difficult, especially for discontinued models. That means longer downtime, delayed deliveries, and frustrated customers.

Working with a reputable laser cutting machine manufacturer ensures access to genuine parts, timely support, and stable supply chains. These are things a used machine cannot guarantee.

4. Technology Gap and Energy Efficiency

Modern fiber laser cutting machines are designed for higher energy efficiency, faster piercing, and intelligent automation. By contrast, older CO₂ or early-generation fiber laser cutting systems consume more power and produce more heat, increasing both energy bills and maintenance frequency.

Upgrading to a new system from a trusted laser cutting brand may involve higher initial investment, but the long-term savings in energy and productivity make it the smarter choice.

5. Resale Value and Long-Term ROI

A used laser cutting machine already at midlife has limited resale potential. Its depreciation curve is steep, and its lifespan may not justify even a short-term investment.

On the other hand, a new fiber laser cutting machine from a reputable laser cutting machine manufacturer retains higher value and delivers consistent performance, making it easier to scale production and plan ROI with confidence.

While second-hand laser cutting machines can seem like a bargain, the reality often proves otherwise. Between lower cutting accuracy, uncertain maintenance, and limited technical support, the risks far outweigh the savings.

For businesses aiming at long-term success, partnering with a professional laser cutting machine manufacturer and investing in a modern fiber laser cutting equipment remains the most reliable and cost-effective choice. If you're facing cutting quality issues or considering replacing your old system, our team of experts is here to help. We specialize in fiber laser cutting machines built for precision, efficiency, and durability, backed by comprehensive technical support and global service.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()