-

Product

-

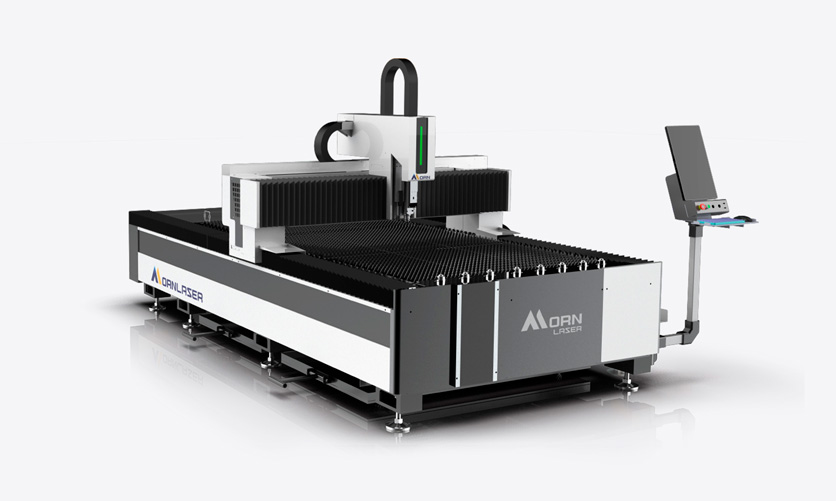

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

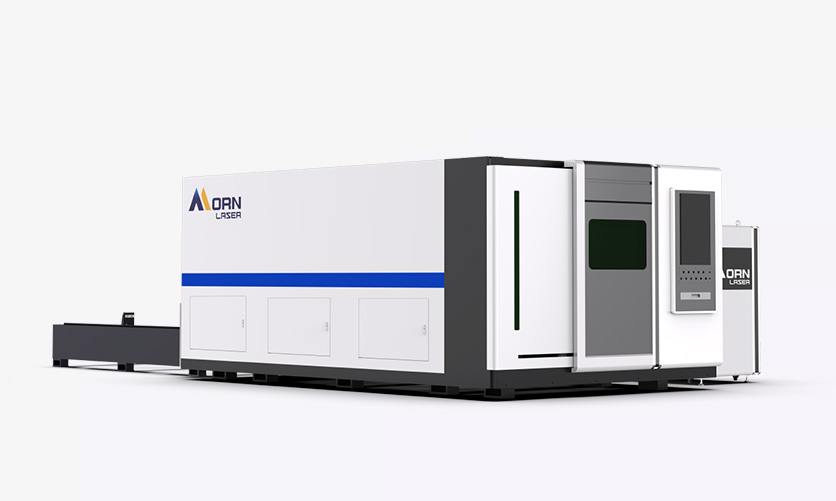

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

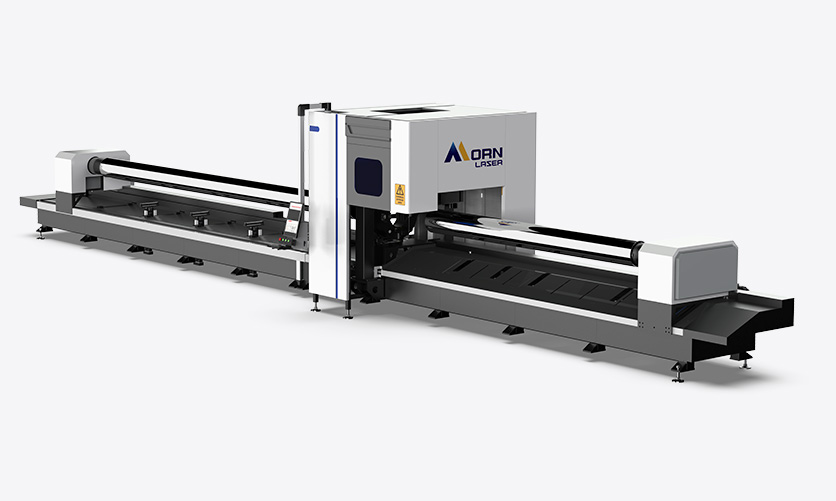

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

16 Routine Maintenance Instructions on Fiber Laser Cutting Machine

2022-10-29Fiber laser cutting machine become more and more popular in recent years. Right maintenance methods for fiber laser cutting machine are key factors to keep its good performance and prolong its service life. Here we offer some instructions and precautions on fiber laser cutter maintenance for both experienced users and beginners.

1. If cutting with air, pressure of the air compressor should at least reach to 1.2-1.4 MPA to achieve perfect cutting result (only suitable for maximum 1.5 mm metals).

2. Refrigeration dryer and water removal device should be installed in the outlet of air compressor.

3.Gases in the tube must be let out before turning off the fiber laser metal cutting machine, to prevent the tube from cracking.

4. Remove the water from compressor and refrigeration dryer once a day.

5. Water temperature should be set as 25-30 Celsius degree during cutting process. Purified water mixed with 30% amount of ethanol should be used in summer and in winter purified water mixed with 50% amount ethanol or only antifreeze should be used to help cut.

6.The right boot steps should be: main power, water-cooling machine, key switch, computer, laser generator (make sure the water-cooling machine has reached to the fixed temperature).

7. Add lubricating oil once in a week.

8. Gear oil and screw oil should be smeared evenly once in a month.

9. The protective glass should be cleaned with ethanol and swab before every use. It cannot be put into the laser head until it’s completely dry.

10. The laser head should get back to the origin after every use, and calibrate the height controller every day to ensure the perfect cutting result.

11. Confirm the cutting parameters before the start and check “Only Process the Selected Image” option to prevent accidents.

12. Check the “Software Limitation” option to keep safety.

13. Check whether the size of the to-be-cut image is proper and whether the two diagonals of rectangle have equal length.

14. Laser head should move along the frame before cutting and make sure the laser head works inside the material surface.

15. Hold the remote controller in hand during the whole cutting process, in which you can press the “Emergency Stop” button if an emergency happens. Emergency has to be solved before restart.

16.You can press the “Pause” button during the cutting process to readjust machine parameters or check the cutting result. Then press the “Continue” button on the computer screen to restart.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()