-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

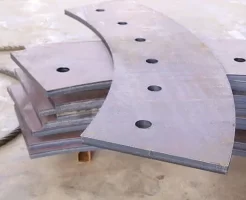

Fiber Laser Cutting Machine Creates High-Quality and Safe Food Machinery

2022-10-08The safety and quality of food machinery have a direct influence on people’s health and food safety. Nowadays, food production is progressed on the way of mechanization, automation, professionalization and scale expansion, aiming to promote wholesomeness, safety and production efficiency. In the course of improving food safety, food machinery safety is an essential chain that decides whether people have access to healthy and safe food. Hopefully, food machinery made by fiber laser cutting machine can build the first line of defense.

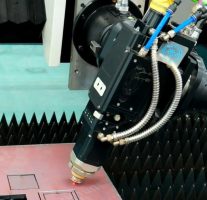

Compared with traditional processing technology, fiber laser cutting machine has outstanding advantages in food machinery production. Traditional production methods require open mold, stamping, shearing plates and bending process, consuming more molds with lower efficiency and more cost. While fiber laser cutting technology boasts the following 7 advantages:

1. Safer and cleaner

During the cutting process, fiber laser cutter doesn’t touch the surface of materials directly so that it can keep the safety and wholesomeness of food machinery.

2. Higher precision

Fiber laser cutting machine can cut with high precise cutting edge of 0.1~0.2mm.

3. Smoother cutting edge

No rags exist in laser cutting edge which is also so smooth that almost no secondary processing is required to produce high-end food machinery.

4. Faster cutting speed

Fiber laser cutting machine cuts metal at a fast speed, which effectively improves the production efficiency of food machinery production.

5. More suitable for processing large-size materials

Fiber laser cutting technology no needs molds and can avoid the deformation of materials. This can greatly reduce the production cost and enhance the quality and grade of food machinery.

6. Saving more materials and cost

Computer programming is applied by fiber laser cutter to increase the utilization efficiency of materials to the utmost extent, in which way, lots of materials and cost can be saved.

7. More suitable for developing new products

Once the product design drawings are formed, laser cutting process can be conducted immediately. Therefore new types of food machinery can be produced in this way.

To sum up, the fiber laser cutting machine not only improves the production cycle of the food machinery manufacturing industry, but also greatly reduces the production cost and improves the competitiveness of the industry. In the future development of food machinery, the efficient application of laser cutting machines will further lead the industry towards digitization and intelligence. Any thoughts about this article, welcome to comment!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()