-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Common Questions of Fiber Laser Cutting Machine

2022-09-14With the development of fiber laser cutting machine and laser cutting technology, the field of laser cutting machine applications has become more and more extensive, and more and more materials are applicable. But do you really know the fiber laser cutting machine? today some content about laser cutting machine will be shared with you:

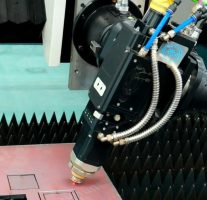

1. What is the working principle of a fiber laser cutting machine?

Fiber laser cutting is to use a focused high-power-density laser beam to irradiate the workpiece, so that the irradiated material quickly melts, vaporizes, ablates, or reaches the ignition point. At the same time, the molten material is blown out by the high-speed airflow coaxial with the beam and moved through the CNC mechanical system The light spot irradiates the position to realize a thermal cutting method for cutting the workpiece.

2.Is the fiber laser cutting machine dangerous to operate?

Fiber laser cutting machine is a very environmentally friendly cutting method, generally speaking, there is no harm to the body. Compared with plasma cutting and other traditional cutting method, laser cutting produces less dust, weak light, and low noise. However, if the correct and safe operation method is not followed, it will also cause personal injury to the user or damage to the machine.

Beware of flammable materials when using the machine. Certain materials are not allowed to be cut on a laser cutting machine, including foam core materials, any PVC materials, etc.

During the working process of the machine, it is forbidden for the operator to leave without authorization to avoid unnecessary losses.

Do not stare at the laser processing operation. It is prohibited to observe laser light through binoculars, microscope, magnifying glass, etc.

Do not store explosive or flammable materials in the laser processing area.

3.What are the factors that affect the accuracy of fiber laser cutting machines?

There are many factors that affect the accuracy of fiber laser cutting machine, and some are determined by the equipment itself, such as the accuracy of the mechanical system, the degree of vibration of the worktable, the quality of the laser beam, the influence of auxiliary gas and the nozzle, etc.;

some are inherent factors of the material, such as the physical and chemical properties of the material, The reflectivity of the material, etc.;

There are also some factors that are selected according to the specific processing object and user quality requirements, and corresponding adjustments are made to determine the relevant parameters, such as output power, focus position, cutting speed and auxiliary gas.

4.What is the cutting thickness of the fiber laser cutting machine?

At present, the thickness of the laser cutting machine generally does not exceed 70mm.

5. What are the advantages and applied industries of fiber laser cutting machines?

Laser cutting machines are widely used in automobile manufacturing, kitchenware industry, sheet metal processing, advertising industry, machinery manufacturing, etc. due to its wide cutting range, high cutting speed, narrow cutting seam, good cutting quality, small heat-affected zone, and flexible processing.

MORN company is professional for fiber laser cutting machine, if you need any more information, please contact us, we will try our best to help you.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()