-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

What Industries Are Fiber Laser Cleaning Machines Suitable for?

2022-08-02With the increasing awareness of environmental protection and safety, the types of chemicals that can be used in industrial cleaning will become less and less. More and more companies choose to use fiber laser cleaning machines to replace the traditional cleaning mode. Fiber laser cleaning machines can not only be used to clean organic pollutants, but also to clean inorganic substances, including metal rust, metal particles, dust, etc. Today, laser cleaning machines have been practically used in the following industries, and these technologies are very mature and widely used.

01. Aviation/Shipbuilding:

Laser cleaning is a non-contact cleaning method, which will not cause mechanical damage or surface wear, and prolong the service life of the tool.

02. Automotive industry:

The fiber laser cleaning machine can selectively clean the attachments on the surface of automobile parts without damaging the surface of the material, and achieve precise positioning and cleaning.

03. Food processing industry:

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid and solid strong impact cleaning, and high-frequency ultrasonic cleaning, fiber laser cleaning machines do not use any chemicals and cleaning fluids, no medium residue, and no secondary pollution.

04. Production and processing industry:

Fiber laser cleaning machines can be used not only to clean organic pollutants, but also to clean inorganic substances, including metal rust, metal particles, dust, etc.

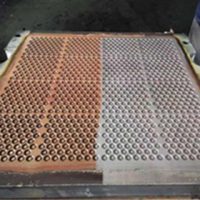

05. Tire industry:

Every year, tire manufacturers around the world manufacture hundreds of millions of tires, and the cleaning of tire molds during the production process must be fast and reliable, and save downtime. The laser cleaning machine can clean the surface of the mold, and it can be put into use after cleaning without waiting.

06. Electronics industry:

The precision machinery industry often needs to remove the acids and mineral oils used for lubrication and corrosion resistance from parts, usually by chemical methods. Chemical cleaning often leaves residues. The fiber laser cleaning machine has no other consumables during cleaning, and there is no residue after cleaning. The cleaned waste is mainly solid powder, which is small in size, easy to store and recyclable.

In summary, laser cleaning machines play an important role in many fields, not only the above industries have been applied, but also the construction industry, mold industry, etc., and the application market has broad prospects. With the rapid development of science and technology, laser cleaning technology will be more and more used in various fields of people’s production and life.

Continuous wave laser cleaning machine - 1

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()