-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Morn Fiber Laser Cutting Machine Promotes the Development of Elevator Manufacturing Industry

2024-09-03At a rough estimate, the scale of the elevator manufacturing market has reached hundreds of billions now. While the elevator industry is booming, traditional cutting method cannot meet customer needs in terms of material processing cycle or cutting quality. Fiber laser cutting machine came into being!

Fiber laser cutting machine has the characteristics of high precision, fast cutting, not limited to cutting pattern restrictions, etc., and it will gradually improve or replace traditional metal cutting process equipment. The specific advantages of fiber laser cutting machine in elevator manufacturing industry are as follows:

1. It will have better cutting effect, when using fiber laser cuttig machine

First, the cutting precision is higher, and the cutting precision can reach ±0.03mm;

Second, the cutting surface is smooth and beautiful, which can greatly reduce the roughness of the surface;

Third, the deformation of workpiece is small.

2. It will have higher cutting efficiency, when using fiber laser cutting machine

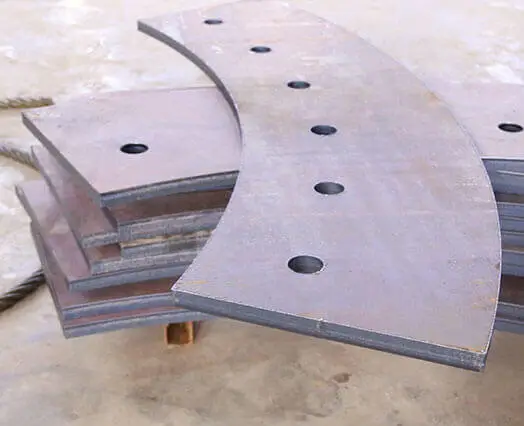

There are many types of elevator workpieces and large batches, and the application of laser cutting machine can greatly improve production efficiency. When cutting metal sheet, the workpiece can be processed without preparing a mold.

3. It will have higher processing flexibility, when using a fiber laser cutting machine

With the improvement of people’s aesthetic level, the styles of products have also increased, and the shapes and varieties of products have increased. Laser cutting has a high degree of automation and intelligence, and can handle various special-shaped workpiece processing.

If you also want to buy a laser cutting machine to improve processing efficiency, our hot-selling model 3000w MT-L1530F fiber laser cutting machine is recommended to you, which can meet the cutting requirements of carbon steel, stainless steel and other metal plates. MT-L1530F is an ideal choice for medium and thin metal sheet processing and it is perfect for cutting elevator steel plates!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()