-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

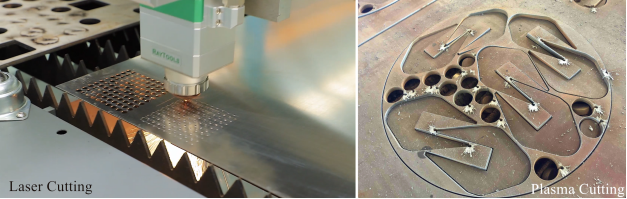

Why Laser Cutting is the Future of Metal Fabrication: A Comparison with Plasma Cutting

2024-10-09As the metal processing industry continues to innovate, the choice of cutting technology plays a crucial role in determining efficiency, cost-effectiveness and product quality. While plasma cutting has been a traditional method for metal fabrication, the rise of metal laser cutting technology is reshaping the metal cutting method. This article discusses why laser cutting is becoming the preferred method for metal fabrication.

1. Superior Cutting Precision

Fiber laser cutting is renowned for its exceptional precision, often achieving tolerances of ±0.05m or better, and it allows for intricate shapes and fine details.In contrast, plasma cutting can produce rougher edges and less accurate cuts, leading to higher scrap rates and additional processing time.

2. Smaller Heat-Affected Zone

The process of laser cutting results in a smaller heat-affected zone, and it will help to reduce thermal distortion. Plasma cutting, due to its high-temperature arc, often leads to thermal distortion, impacting the product quality.

3. Reduced Post-Cutting Processing

The edges produced by laser cutting are typically smooth and clean, minimizing the need for subsequent grinding or polishing. This not only saves time and labor costs but also enhances overall production efficiency. Plasma cutting, on the other hand, typically requires more finishing work to smooth out rough edges, which can slow down production schedules.

In summary, laser cutting technology outperforms plasma cutting in precision, efficiency and heat-affected zones, making it an increasingly attractive option for businesses. Fiber laser cutting machine is poised to play an increasingly vital role in the metal fabrication.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()