-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

The Cost-Effective Advantage of Laser Cutting in Manufacturing

2024-10-30In the quest for efficiency and cost reduction, manufacturers are increasingly turning to advanced technologies, with laser cutting standing out as a preferred choice. This method utilizes a laser cutter machine to achieve high precision in cutting various metal materials, resulting in significant savings and improved production results.

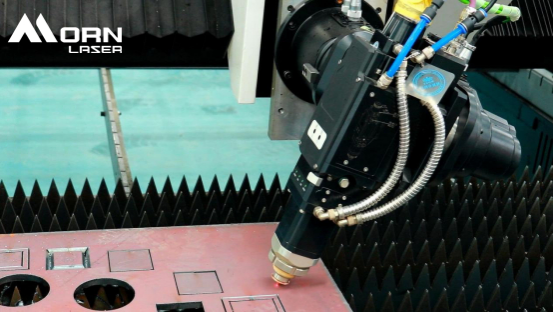

The CNC laser cutting machine irradiates the cutting area with a high-energy-density laser beam, causing the surface of the metal material to evaporate or melt, while forming tiny slits on the surface of the material, thereby achieving the purpose of precise cutting. This precision minimizes errors and reduces the need for costly rework, which can drain resources and time. Additionally, the capability of laser cutting to handle intricate designs means that manufacturers can produce complex parts in one operation, further optimizing production workflows.

One of the key benefits of laser cutting is its ability to reduce material waste. Traditional cutting techniques often generate a significant amount of scrap, leading to higher costs for raw materials. In contrast, laser cutting utilizes materials more efficiently, allowing manufacturers to maximize their input resources. This reduction in waste not only lowers material costs but also contributes to a more sustainable manufacturing process.

The speed of laser cutting machines is another factor that enhances their cost-effectiveness. The rapid cutting speeds can significantly decrease production times, enabling manufacturers to meet tight deadlines and respond swiftly to market changes. With reduced lead times, the companies can improve customer satisfaction and potentially increase sales, as they are better equipped to fulfill orders promptly.

Additionally, the versatility of laser cutting allows manufacturers to diversify their product offerings, tapping into new markets and revenue streams.

In summary, the adoption of laser cutting technology presents a powerful opportunity for manufacturers aiming to reduce production costs. The precision, efficiency, and versatility of materials that CNC laser cutting machines offer make them a valuable asset in modern manufacturing. The long-term savings and increased productivity make metal laser cutter a worthwhile consideration for manufacturers aiming to thrive in a competitive environment.

If you also want to buy a fiber laser cutting machine, or are interested in the laser cutting machine price or other details, please feel free to contact us!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()