-

Product

-

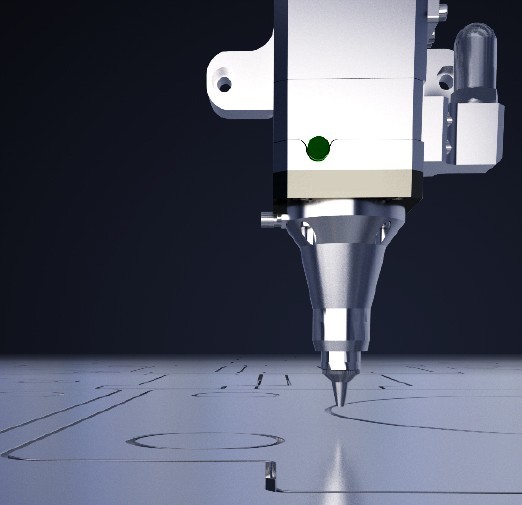

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Comparison between Fiber Laser Cutting Machine and Traditional Cutting Machine

2024-11-11In modern manufacturing, choosing the right cutting technology is crucial for improving production efficiency and product quality. With advancements in technology,fiber laser cutting machines have become the preferred choice for many businesses. This article will provide a detailed comparison between fiber laser cutting machines and traditional cutting machines, highlighting their respective advantages and disadvantages. We will also introduce a well-known laser equipment manufacturer, Mornlaser, to help you better understand the market options.

1. Cutting Precision

Fiber Laser Cutting Machine:

High Precision: Fiber laser cutting machines use high-energy-density laser beams to cut materials, achieving precision at the micron level. This is particularly important for cutting intricate parts and complex shapes.

Non-contact Cutting: Laser cutting is non-contact, meaning it does not apply mechanical stress to the material, thus avoiding deformation and damage.

Traditional Cutting Machine:

Lower Precision: Traditional cutting methods such as shearing, punching, and flame cutting have lower precision and can produce burrs and deformation.

Contact Cutting: Traditional cutting machines typically require physical contact with the material, which can lead to surface damage or deformation.

2. Cutting Speed

Fiber Laser Cutting Machine:

High-Speed Cutting: Fiber laser cutting machines are very fast, especially for thin materials. This significantly improves production efficiency and reduces costs.

High Automation: Modern fiber laser cutting machines are often equipped with advanced automation control systems, enabling unmanned operation and further enhancing efficiency.

Traditional Cutting Machine:

Slower Speed: Traditional cutting methods are generally slower, particularly when dealing with complex shapes and fine structures.

More Manual Intervention: Traditional cutting machines often require more manual operation, increasing labor costs and the risk of errors.

3. Material Compatibility

Fiber Laser Cutting Machine:

Wide Range of Materials: Fiber laser cutting machines can cut a variety of materials, including metals, plastics, ceramics, and glass. This makes them suitable for use in multiple industries.

High Flexibility: Laser cutting parameters can be quickly adjusted to accommodate different materials and thicknesses.

Traditional Cutting Machine:

Limited Material Compatibility: Traditional cutting methods are usually limited to specific types of materials, such as metal sheets. For non-metal or special materials, other cutting methods may be required.

Fixed Parameters: Adjusting parameters in traditional cutting machines can be difficult, making it challenging to adapt to different material needs.

4. Maintenance Costs

Fiber Laser Cutting Machine:

Low Maintenance Costs: Fiber laser cutting machines have a compact structure and relatively low maintenance costs. The laser source has a long lifespan, reducing replacement frequency.

Less Consumables: Laser cutting processes consume fewer materials, further reducing operational costs.

Traditional Cutting Machine:

High Maintenance Costs: Traditional cutting machines have more mechanical components that wear out easily, requiring regular maintenance and replacement.

More Consumables: Traditional cutting methods require more consumables, such as cutting tools and grinding wheels, increasing operational costs.

5. Environmental Friendliness

Fiber Laser Cutting Machine:

Environmentally Friendly: Laser cutting produces less heat and waste, minimizing environmental impact.

No Pollution: Laser cutting does not use chemical substances, avoiding the generation of harmful gases or liquids, making it more environmentally friendly.

Traditional Cutting Machine:

Environmental Pollution: Traditional cutting methods can produce large amounts of dust, noise, and harmful gases, affecting the environment and worker health.

Chemical Substances: Some traditional cutting methods require the use of chemical substances, posing potential safety hazards.

Mornlaser: Your Ideal Choice

Founded in 2008,Mornlaser is a comprehensive intelligent equipment manufacturing company specializing in research, development, production, sales, and service. As a one-stop industrial laser solution provider, Mornlaser stands out with its advanced production technology, reliable service, and commitment to lifelong product responsibility. It has become the preferred laser brand for tens of thousands of customers worldwide.

Whether you are looking for a high-precision, high-speed fiber laser cutting machine or a multifunctional device capable of handling various materials, Mornlaser can offer you the best solutions. Our products are not only highly efficient but also easy to operate and maintain, making them ideal for enhancing your production efficiency and product quality.

Conclusion

Compared to traditional cutting machines, fiber laser cutting machines offer higher precision, faster speed, wider material compatibility, and lower maintenance costs. If you want to improve your production efficiency and product quality, a fiber laser cutting machine is undoubtedly the better choice. Mornlaser, as a leading brand in the industry, will provide you with the highest quality products and services, helping you stand out in a competitive market.

We hope this article helps you better understand the differences between fiber laser cutting machines and traditional cutting machines. If you have any questions or need further assistance, feel free to contact Mornlaser.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()