-

Product

-

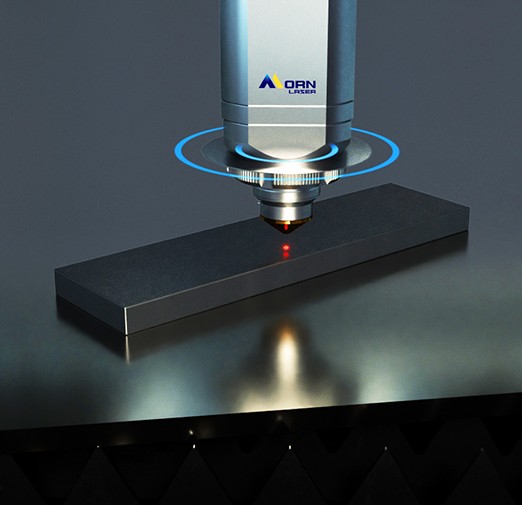

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Five Tips to Ensure Efficient Operation of Fiber Laser Cutting Machines

2024-11-11Fiber laser cutting machines are highly efficient cutting tools that not only significantly improve production efficiency but also ensure cutting quality. To maintain their optimal performance, regular maintenance and optimization are essential. This article will share five practical tips to help you ensure the efficient operation of fiber laser cutting machines. We will also briefly introduce a well-known laser equipment manufacturer, Mornlaser, to help you better understand the quality options available in the market.

1. Regularly Clean the Optical Lenses

Why It's Important:

Optical lenses are a critical component of fiber laser cutting machines. Any dirt or dust on the lenses can affect the quality of the laser beam, thereby impacting the cutting results.

How to Do It:

Use Specialized Cleaning Agents: Choose cleaning agents specifically designed for optical lenses to avoid using corrosive substances. There are many specialized cleaning agents available that can effectively remove dirt without damaging the lens surface.

Gentle Wiping: Use a soft, lint-free cloth to gently wipe the lenses to prevent scratching. You can first use a blower or compressed air to remove any loose dust before wiping with the cleaning agent and cloth.

Regular Inspection: Check the lenses for stains or scratches before and after each use, and clean them promptly. This is especially important if you are working in a dusty environment.

2. Keep the Cooling System Clean

Why It's Important:

The cooling system maintains the operating temperature of the laser, and overheating can affect the performance and lifespan of the laser.

How to Do It:

Regularly Replace Coolant: Change the coolant according to the manufacturer's recommended intervals to ensure its cleanliness. Clean coolant is crucial for effective cooling.

Check Filters: Regularly inspect the filters in the cooling system and clean or replace them if they are clogged. Clogged filters can reduce cooling efficiency, leading to overheating.

Monitor Temperature: Use temperature sensors to monitor the cooling system's temperature and ensure it stays within the normal range. If you notice abnormal temperature increases, stop the machine and check for issues.

3. Clean the Cutting Head and Nozzle

Why It's Important:

The cleanliness of the cutting head and nozzle directly affects the focus of the laser beam and the gas flow. A dirty nozzle can lead to a decline in cutting quality.

How to Do It:

Regular Cleaning: After each use, blow off the cutting head and nozzle with compressed air to remove residual chips and dust. You can use a small brush or cotton swab to clean hard-to-reach areas.

Inspect Nozzle: Regularly check the nozzle for damage or deformation and replace it if necessary. Damaged nozzles can affect the focus of the laser beam, leading to poor cutting results.

4. Check and Maintain the Gas Supply System

Why It's Important:

The gas supply system provides the auxiliary gases needed for cutting, such as oxygen and nitrogen. Ensuring the purity and stability of the gas is crucial.

How to Do It:

Regularly Inspect Gas Cylinders: Ensure that the pressure gauges and valves on the gas cylinders are functioning properly to prevent leaks. You can use soapy water to check for leaks at the connections; if bubbles appear, there is a leak that needs to be fixed.

Filters and Dryers: Regularly inspect and replace the filters and dryers in the gas supply system to ensure the purity of the gas. These components help remove impurities and moisture from the gas, ensuring its purity.

Pressure Regulation: Adjust the gas pressure according to the material and thickness being cut to ensure optimal cutting results. Different materials and thicknesses require different gas pressures, so consult the user manual or technical specifications for guidance.

5. Regularly Calibrate the Laser

Why It's Important:

Calibrating the laser ensures that the focal point of the laser beam is accurate, improving cutting quality and efficiency.

How to Do It:

Regular Calibration: Follow the manufacturer's recommended intervals for laser calibration, typically at least once a year. Regular calibration helps maintain the accuracy of the laser beam's focal point.

Use Professional Tools: Use professional calibration tools and software to ensure accuracy. These tools provide precise data to help you adjust the laser settings correctly.

Record Data: Record relevant data after each calibration for future reference and comparison. Keeping records helps you track the performance of the laser over time and identify any issues early.

Additional Practical Tips

In addition to these five basic maintenance tips, here are some extra tips to further enhance the performance of your fiber laser cutting machine:

Lubricate Moving Parts Regularly: The moving parts of a fiber laser cutting machine need regular lubrication to reduce wear and friction. Use appropriate lubricants or greases and follow the manufacturer's recommendations.

Check Cables and Connectors: Regularly inspect cables and connectors for any damage or looseness to ensure all connections are secure and reliable. Damaged cables and connectors can cause equipment failure or performance issues.

Maintain a Clean Work Environment: Keeping the work environment clean can reduce the impact of dust and debris on the equipment. Regularly clean the worktable and floor to ensure there are no obstructions around the machine.

Train Operators: Ensure operators receive adequate training and are familiar with the machine's operation and maintenance procedures. Well-trained operators can use the equipment more effectively and reduce the risk of errors and damage.

Mornlaser: Your Ideal Choice

Mornlaser was founded in 2008 and is a comprehensive intelligent equipment manufacturing high-tech enterprise that integrates R&D, production, sales, and service. As a one-stop industrial laser solution provider, Mornlaser is known for its advanced production technology and has become the preferred laser brand for tens of thousands of customers worldwide. Mornlaser's main products include fiber laser cutting machines, laser cleaning machines, and laser welding machines, which are widely used in various industries.

Conclusion

By following these five tips and additional practical advice, you can ensure that your fiber laser cutting machine operates at its best, thereby improving production efficiency and cutting quality. If you have any questions or need further assistance, feel free to contact Mornlaser. We are committed to providing you with the highest quality products and services to help you stand out in a competitive market.

We hope this article helps you better understand how to ensure the efficient operation of your fiber laser cutting machine. If you have any questions or need further assistance, please don't hesitate to contact Mornlaser.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()