-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

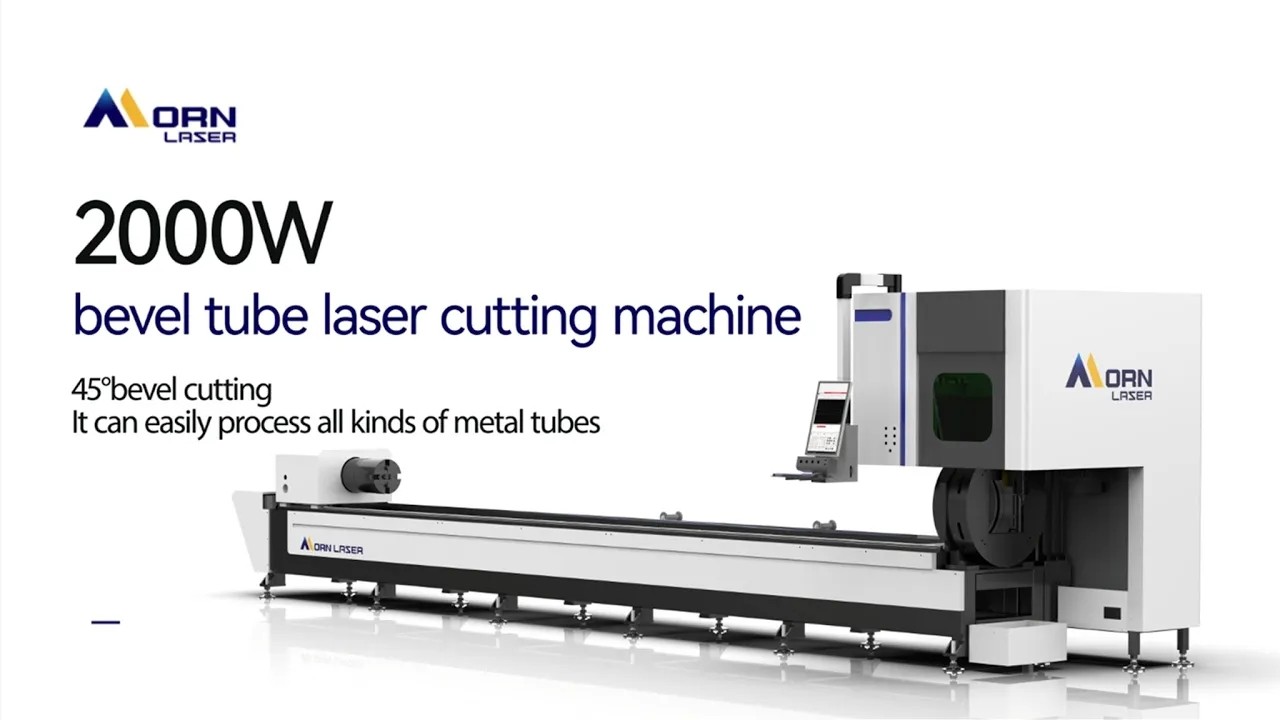

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Applications of Fiber Laser Cutting Machines in Different Industries

2024-11-13Applications of Fiber Laser Cutting Machines in Different Industries

Fiber laser cutting machines are essential tools in modern manufacturing, widely used across multiple industries. With their high precision, speed, and flexibility, fiber laser cutting machines can meet a wide range of complex processing needs. This article will introduce several application examples of fiber laser cutting machines in different industries, showcasing their advantages and effectiveness in practical production.

1. Metal Fabrication Industry

Application Examples:

Stainless Steel Sheet Cutting: Fiber laser cutting machines can efficiently cut stainless steel sheets, ensuring smooth and burr-free edges. They are suitable for kitchenware, medical devices, and other applications.

Carbon Steel Plate Cutting: For thicker carbon steel plates, fiber laser cutting machines can handle the task with ease, offering fast cutting speeds and minimal heat-affected zones, preserving the material's mechanical properties.

Advantages:

High Precision: Cutting accuracy can reach 0.1mm, ensuring high-quality products.

High Efficiency: Fast cutting speeds and high production efficiency make them ideal for large-scale production.

2. Automotive Manufacturing Industry

Application Examples:

Body Parts Cutting: Fiber laser cutting machines can precisely cut various body parts, such as door frames and fenders, ensuring accurate dimensions and smooth surfaces.

Exhaust System Cutting: Used to cut pipes for automotive exhaust systems, ensuring their sealability and durability.

Advantages:

Flexibility: Capable of cutting parts of different shapes and sizes.

High Quality: Smooth cutting edges eliminate the need for additional processing, improving production efficiency.

3. Electronics Manufacturing Industry

Application Examples:

Circuit Board Cutting: Fiber laser cutting machines can accurately cut circuit boards without damaging the circuits, making them suitable for the production of precision electronic devices.

Smartphone Case Cutting: Used to cut metal cases for smartphones, ensuring an aesthetically pleasing and structurally sound design.

Advantages:

Non-Contact Cutting: Does not exert mechanical stress on the material, ensuring cutting quality.

Precision Processing: Suitable for the processing of precision electronic components, ensuring high reliability of the products.

4. Medical Device Industry

Application Examples:

Medical Instrument Cutting: Fiber laser cutting machines can precisely cut medical instruments like surgical blades and orthopedic implants, ensuring high precision and safety.

Medical Equipment Manufacturing: Used to cut casings and internal components of medical equipment, ensuring reliability and durability.

Advantages:

High Precision: High cutting accuracy ensures the high quality of medical products.

Sterile Cutting: The cutting process does not produce dust, maintaining the cleanliness of the cutting area.

5. Aerospace Industry

Application Examples:

Aircraft Parts Cutting: Fiber laser cutting machines can precisely cut aircraft parts such as fuselage skins and engine blades, ensuring high strength and lightweight properties.

Satellite Component Cutting: Used to cut various components of satellites, ensuring precise dimensions and reliable performance.

Advantages:

High Precision: High cutting accuracy meets the stringent requirements of the aerospace industry.

High Efficiency: Fast cutting speeds and high production efficiency make them suitable for complex part processing.

Morn: Professional Laser Solutions Provider

Founded in 2008, Morn is a Chinese high-tech enterprise that integrates R&D, production, sales, and service into a comprehensive smart equipment manufacturing company. As a one-stop industrial laser solutions provider, Morn leverages cutting-edge production technology, reliable service, and a commitment to lifelong product responsibility to become the preferred laser brand for tens of thousands of global customers. We continuously innovate, dedicated to providing customers with efficient, precise, and environmentally friendly laser cutting solutions.

Conclusion

The applications of fiber laser cutting machines in different industries demonstrate their wide applicability and superior performance. By understanding these application examples, users can better leverage the advantages of fiber laser cutting machines to improve production efficiency and product quality. If you have any questions or need further assistance, feel free to contact Morn. We are committed to providing you with the highest quality products and services to help you stand out in a competitive market.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()