-

Product

-

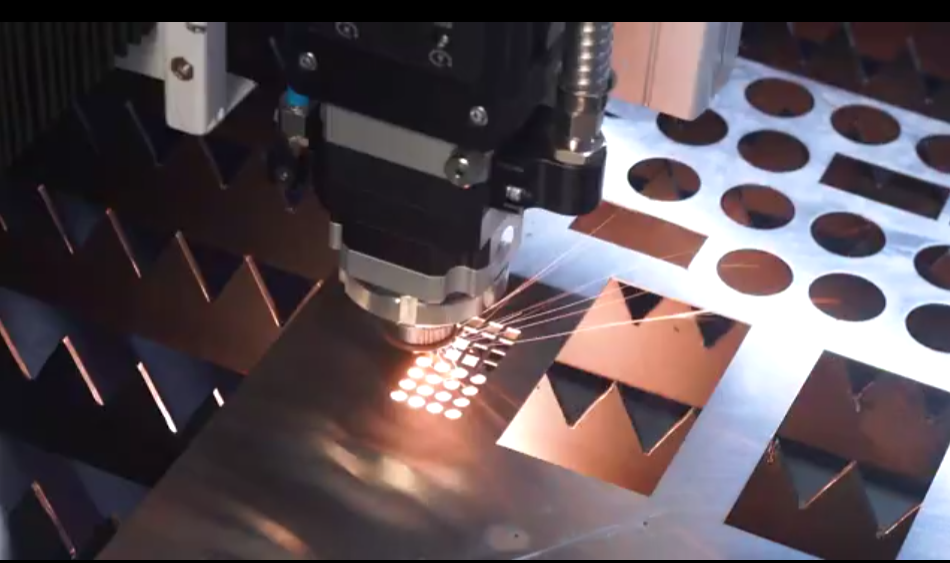

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

How Small and Medium Enterprises Can Find the Right Price for Fiber Laser Cutting Machines

2024-11-14How Small and Medium Enterprises Can Find the Right Price for Fiber Laser Cutting Machines

For small and medium enterprises (SMEs), choosing the right fiber laser cutting machine and finding the right price is a crucial task. Fiber laser cutting machines not only improve production efficiency but also enhance product quality. However, how can SMEs find the right price within a limited budget? This article offers practical tips to help you navigate this process.

1. Define Your Budget and Requirements

1.1 Set Your Budget

Total Budget: First, define your total budget, which should include the cost of the equipment, installation, training, and initial maintenance.

Reserve Contingency Funds: It is advisable to reserve some contingency funds to cover unexpected expenses or future upgrades.

1.2 Determine Your Needs

Material Type: Identify the primary materials you need to cut, such as metals or plastics.

Material Thickness: Determine the maximum thickness of the materials you need to cut and select the appropriate laser power.

Application Areas: Consider the specific application areas where the equipment will be used, such as sheet metal processing or craft making.

2. Understand Market Conditions

2.1 Multi-Channel Quotations

Online Research: Use search engines, e-commerce platforms, and professional forums to gather quotes from multiple suppliers.

Industry Trade Shows: Attend industry trade shows to interact with multiple suppliers and stay updated on the latest market conditions.

2.2 Compare Prices and Performance

Performance Comparison: Compare the performance of different suppliers' equipment, such as laser power, cutting precision, and work efficiency.

Price Comparison: Compare the quotes from different suppliers to choose the most cost-effective option.

3. Choose the Right Laser Power

3.1 Economy Models

Thin Materials: For materials up to 1mm thick, consider a 500W laser cutting machine.

Price Range: Economy models typically cost between 100,000 to 200,000 RMB.

3.2 Mid-Range Models

Medium-Thick Materials: For materials between 1-5mm thick, consider a 1000W laser cutting machine.

Price Range: Mid-range models typically cost between 200,000 to 400,000 RMB.

3.3 High-End Models

Thick Materials: For materials thicker than 5mm, consider a laser cutting machine with 2000W or more.

Price Range: High-end models typically cost over 400,000 RMB.

4. Consider After-Sales Service and Support

4.1 Warranty Policies

Warranty Period: Understand the warranty period offered by the supplier to ensure timely support in case of issues.

Warranty Coverage: Clarify the warranty coverage to know which components and faults are covered.

4.2 Technical Support and Training

Technical Support: Choose suppliers that offer comprehensive technical support to ensure you get timely assistance during use.

Operation Training: Inquire if the supplier provides operation training to help your staff quickly master and operate the equipment.

5. Conduct On-Site Visits and Trials

5.1 On-Site Visits

Supplier Factory: If possible, visit the supplier's factory and equipment to assess the actual condition of the equipment.

User Cases: Visit other users' factories to see how the equipment performs in real-world applications.

5.2 Equipment Trials

Trial Opportunities: Ask suppliers if they offer trial opportunities to personally operate the equipment and experience its performance and ease of use.

Sample Testing: Request sample testing to verify the cutting results and precision of the equipment.

Conclusion

For small and medium enterprises, choosing the right fiber laser cutting machine and finding the right price is a crucial task. By defining your budget and requirements, understanding market conditions, choosing the right laser power, considering after-sales service and support, and conducting on-site visits and trials, you can find the most cost-effective equipment. For more information about fiber laser cutting machines or to discuss your needs, please contact Morn Laser. We are committed to providing you with the highest quality products and services to help you stand out in a competitive market.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()