-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

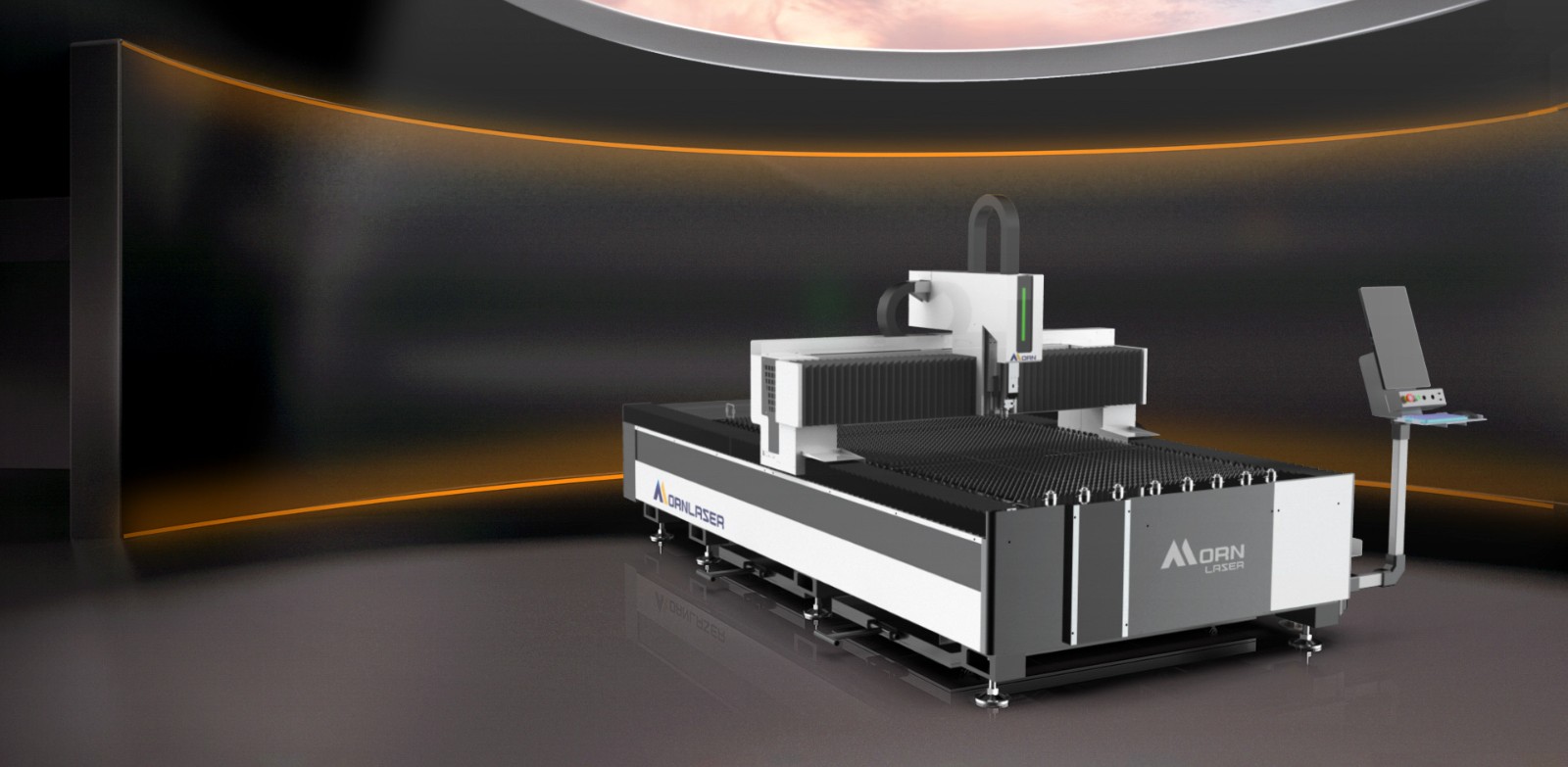

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Chinese Sheet Metal Laser Cutter | Powerful Productivity and Precise Operation

2024-11-15Sheet Metal Laser Cutter: Powerful Productivity and Precise Operation

In modern manufacturing, sheet metal laser cutters have become the preferred choice for many enterprises due to their powerful productivity and precise operation. This article will provide an in-depth look at the advantages and key features of sheet metal laser cutters, helping you better understand this advanced equipment.

1. Automatic Focusing, Hands-Free Operation

1.1 Multi-Function Smart Focusing Laser Head

Automatic Focusing: Sheet metal laser cutters are equipped with multi-function smart focusing laser heads that can automatically adjust the focus to the optimal position. This feature significantly enhances production efficiency and reduces manual intervention, achieving true automation.

2. High Efficiency and Precision, User-Friendly Operation

2.1 Touchscreen Interface

User-Friendly Interface: The devices feature a touchscreen interface that is intuitive and highly compatible. Integrated with CAD, Nest, and CAM modules, the entire process from drawing, nesting to cutting can be completed with just a few mouse clicks, greatly simplifying the operation process.

3. Zoned Dust Extraction System, Efficient Smoke Removal

3.1 Zoned Exhaust System

Clean Production Environment: Sheet metal laser cutters are equipped with a zoned dust extraction system to maintain a clean production environment. Each exhaust port can be independently controlled, with designated exhaust ports for specific areas, ensuring better smoke removal and a cleaner workspace.

4. Dual Exchange Platforms, 10-Second Rapid Swap

4.1 High-Low Platform Speed Exchange

Continuous Production: The machines feature dual exchange platforms with high-low platform speed exchange, significantly reducing downtime. Cutting and material handling can occur simultaneously, enabling continuous production and improving overall efficiency.

5. Intelligent Collision Protection, Safe Operation

5.1 Intelligent Collision Protection

Reduce Damage: Sheet metal laser cutters are equipped with intelligent collision protection. The laser cutting head automatically skips over or avoids tilted workpieces, moving smoothly to the next processing position to prevent collisions, effectively reducing the damage rate of the laser head.

6. Protective Grating, Ensure Safety

6.1 High-Precision Safety Light Curtain

Safety Assurance: The devices are equipped with high-precision safety light curtains, providing the highest level of safety protection for operators and equipment. When personnel or objects accidentally enter the danger zone, the machine automatically detects the beam's movement and pauses operation, ensuring production safety.

7. Industry Applications and Cutting Samples

7.1 Wide Range of Applications

Diverse Uses: Sheet metal laser cutters are widely used in industries such as sheet metal processing, electrical cabinets, elevators, kitchen appliances, and metal windows and doors. They can easily cut stainless steel, carbon steel, galvanized steel, and other metal materials, meeting various industrial needs.

8. Simplified Structure, Economical and Practical

8.1 High-Precision Cutting

Superior Performance: Sheet metal laser cutters have a simplified structure that is economical and practical, while maintaining high-precision cutting. The machines can achieve a maximum acceleration of 1.5G, a maximum联动speed of 140 meters per minute, a maximum stainless steel cutting thickness of 100 millimeters, and a maximum laser power of 30,000 watts, ensuring efficient and stable cutting performance.

Brand Introduction

Morn Laser was founded in 2008 and is a high-tech enterprise specializing in the research, development, production, sales, and service of intelligent manufacturing equipment. As a one-stop industrial laser solution provider, Morn Laser leverages advanced production technology and reliable service to become the preferred laser brand for tens of thousands of customers globally. We are committed to lifelong responsibility for our products, ensuring the best experience and protection for our customers.

Conclusion

Sheet metal laser cutters offer powerful productivity, precise operation, intelligent safety features, and a wide range of applications, making them indispensable tools in modern manufacturing. Through features such as automatic focusing, zoned dust extraction, dual exchange platforms, touchscreen interfaces, intelligent collision protection, and protective grating, sheet metal laser cutters bring significant improvements in production efficiency and cost savings. For more information about sheet metal laser cutters or to discuss your needs, please contact Morn Laser. We are dedicated to providing you with the highest quality products and services to help you stand out in a competitive market.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()