-

Product

-

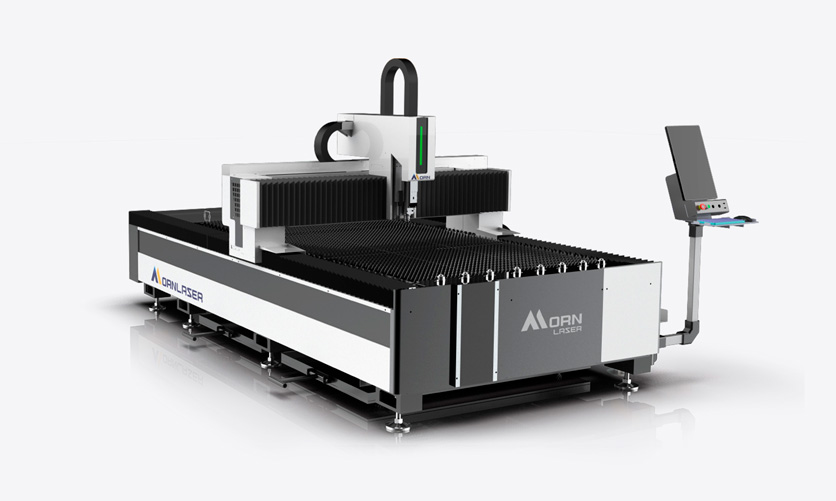

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

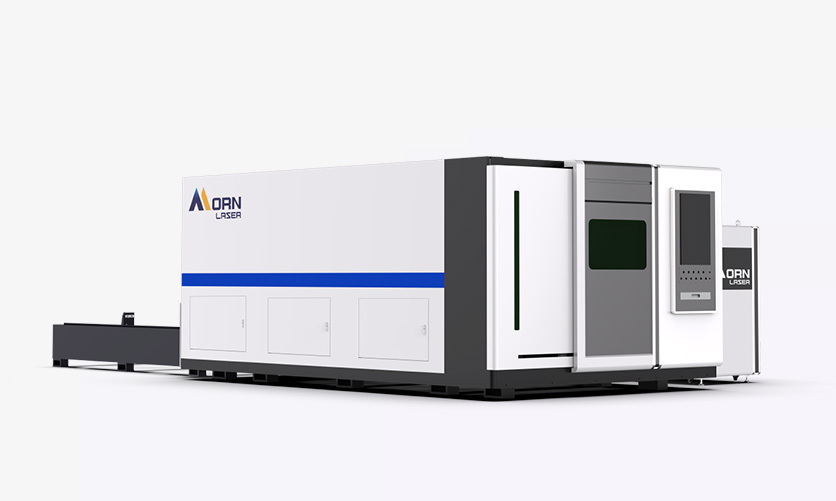

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

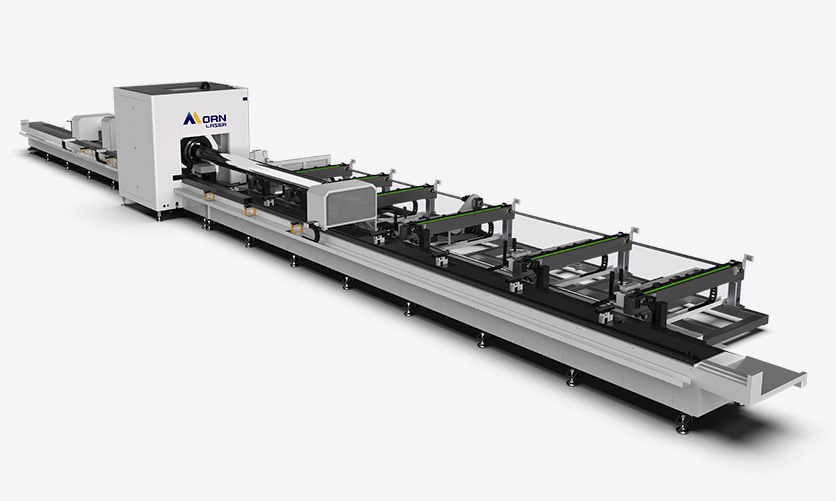

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

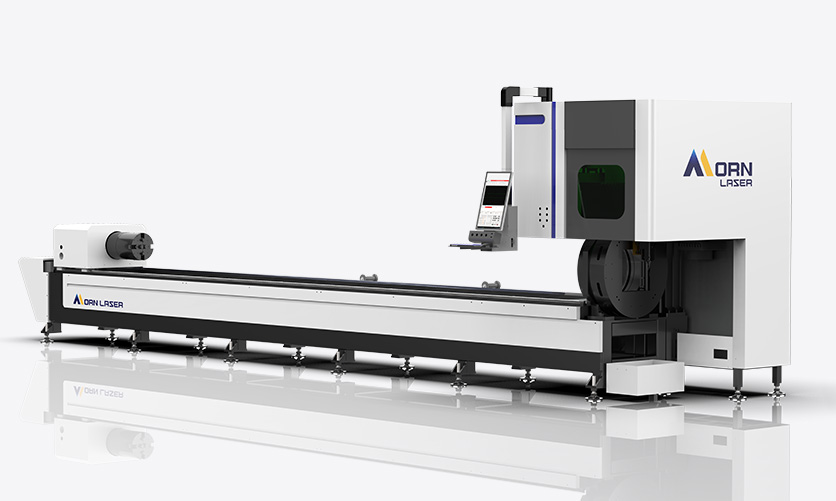

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Pricing

- Contact

Menu

X- home

-

Product >

-

Fiber Laser Cutting Machine: The Best Solution for Cutting Metal Sheets

2023-12-27Nowadays, fiber laser cutting machines play an important role in construction, decoration, furniture, hardware, advertising, machinery and equipment and other industries. Long-term industry experience has convinced people that fiber laser cutting machines are the preferred solution for cutting metal sheets. The reasons can be detailed as follows:

1. Laser cutting of metal sheets is more precise and faster.

Laser cutting can achieve perfect accuracy of 0.02mm. Compared with traditional cutting methods, laser cutting is faster. This effectively ensures the beauty of sheet metal processing and improves production efficiency. At the same time, this is also one of the most convincing factors that makes fiber laser cutting machines stand out among many cutting methods.

2. The price of fiber laser cutting machines is getting lower and lower.

As more and more money and energy are invested in fiber laser cutting technology, the cost of fiber laser cutting machines is decreasing over time. You can buy a fiber laser cutting machine at a reasonable price and make more profits while saving costs.

3. Energy utilization efficiency is higher.

Energy utilization is an important indicator for calculating operating costs. Fiber laser cutting machines can convert fiber laser energy and electrical energy into as much heat as possible. The photoelectric conversion rate is high, which saves production costs.

4. The fiber laser cutting machine is more convenient to operate.

The fiber laser cutting machine adopts a CNC system, and it is easy to operate. Operators only need basic training to get started. However, when operating a fiber laser cutting machine, you should strictly follow the fiber laser cutting machine manufacturer’s instructions for safe operation.

If you plan to buy a fiber laser cutting machine, there are many things to pay attention to. For more information, you can check other posts on our blog or contact us directly to solve your problems.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]() 验证码

验证码