-

Product

-

Fiber laser cutting machine

-

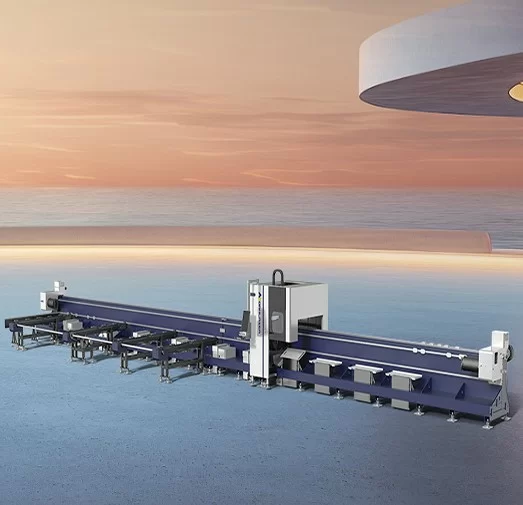

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

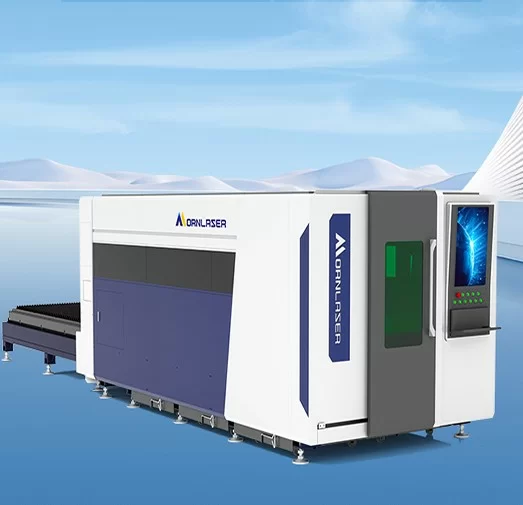

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Pricing

- Contact

Menu

X- home

-

Product >

-

Automated laser cutting, empowering you to effortlessly step into the era of smart manufacturing.

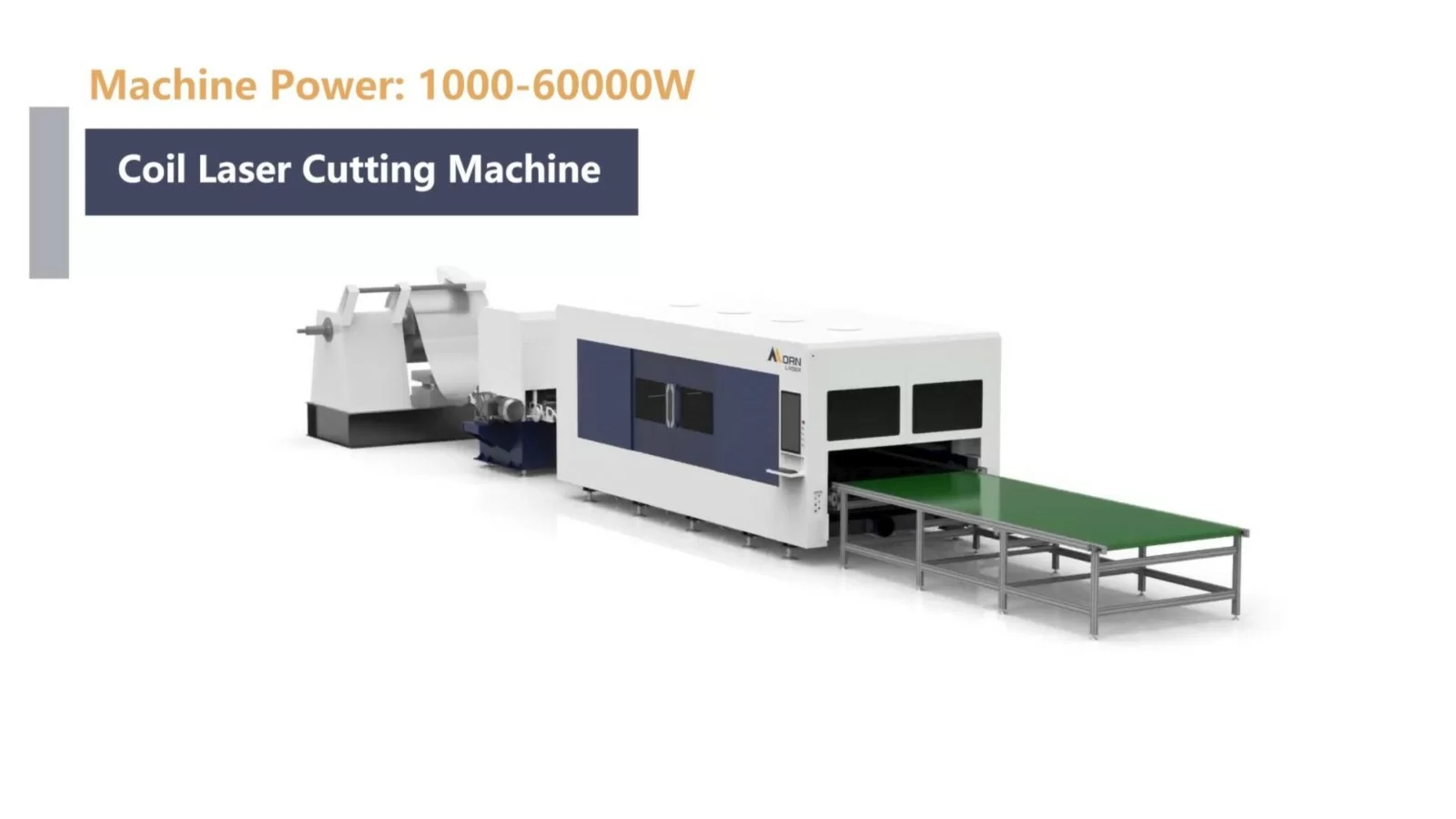

Coil Laser Cutting Machine

1.5GMaximum acceleration140m/minMaximum linkage speed100mmMaximum SS cutting thickness60000wMaximum laser power![Coil Laser Cutting Machine]() Benefits you can get from our Coil Laser Production Line

Benefits you can get from our Coil Laser Production Line![]() High-Level Automation

High-Level Automation![]() Labor Cost Reduction

Labor Cost Reduction![]() Space-saving

Space-saving![]() High Flexibility

High Flexibility![Video Thumbnail]()

![YouTube Logo]()

![]()

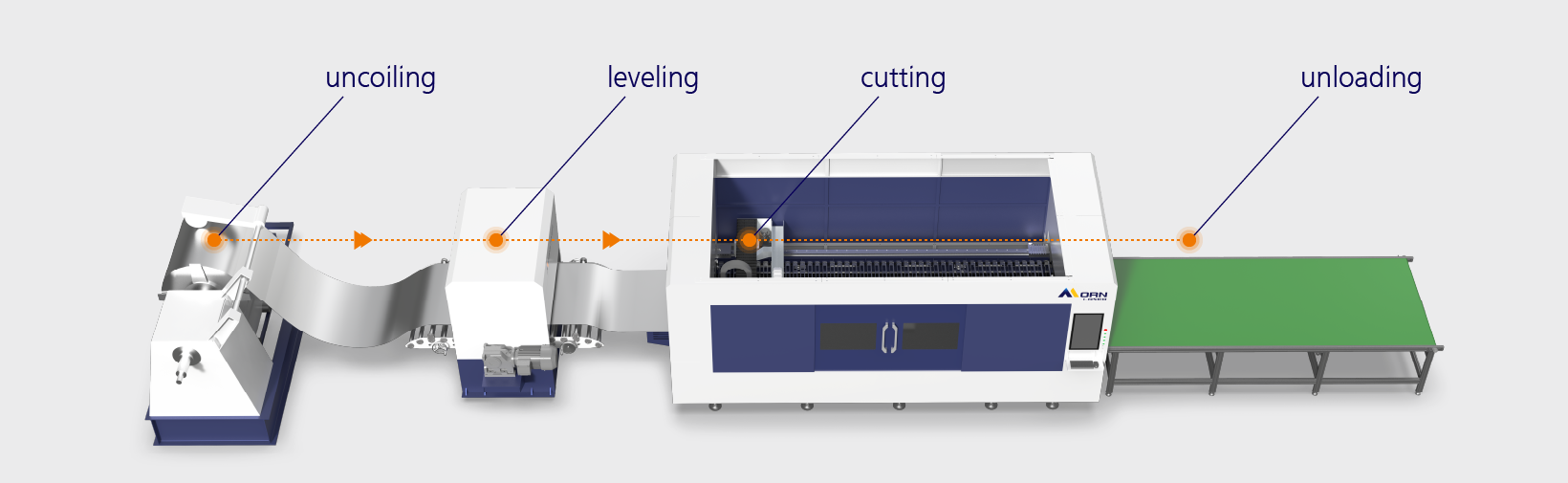

All-in-One-Laser cutting Line:Faster,Smarter Production

Leveling, feeding, cutting, unloading—all in one automated system for seamless, efficient output.

![Laser Cutting]()

Achieve Precision and Efficiency with Laser Cutting

Laser cutting can offer flexible production, one-step forming, no post-processing.

![Laser control system]()

Optimize Production with Intelligent Control System

Our smart cutting system can achieve auto nesting, common-edge cutting, and minimize waste to ensure maximum efficiency.

![Coil Laser Cutting Machine]()

Enhance Automation with Optional Expansion Systems

Customizable smart production systems include film mulching, scrap collection, and automated sorting and palletizing.

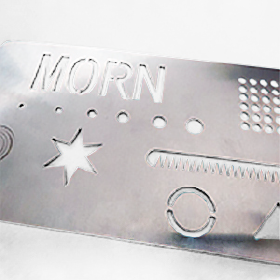

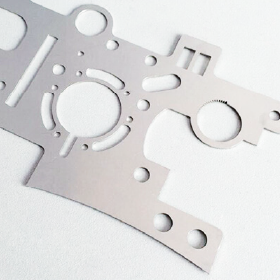

Application & Samples

Favored by metal sheet fabrication factories, automation lines and large fabrication stations, this full cover fiber laser cutting machine fits for mid-thick plate cutting and cuts carbon steel, stainless steel, aluminum, copper, alloy metals effortlessly

![]()

![]()

![]()

![]() Technical Data

Technical DataModel FX-1530 FX-2040 FX-2560 Working Area (Customizable) 3000*1500mm 4000*2000mm 6000*2500mm 12000*2000mm 12000*2500mm Laser Power 2000W/3000W/4000W/6000W/12000W/20000W/30000W/40000W/60000W Repeat Positioning Accuracy ±0.02mm Maximum linkage speed 140m/min Maximum Acceleration Speed 1.5G Power Supply AC380V 50HZ AC220V 60HZ Application & Samples

Favored by metal sheet fabrication factories, automation lines and large fabrication stations, this full cover fiber laser cutting machine fits for mid-thick plate cutting and cuts carbon steel, stainless steel, aluminum, copper, alloy metals effortlessly

![Muestras de corte]()

![Muestras de corte]()

![Muestras de corte]()

![Muestras de corte]()

You may also find these topics interesting

Three-chuck linkage cutting boosts your tube utilization with virtually no tailings. Three-position tube clamping plus follow-up supports ensure stable tube feeding and prevent long tubes from bending. As a result, you profit from high cutting precision, great efficiency and low material costs.

With an integrated design, no disassembly is needed for delivery, and it can be directly put into a container, saving shipping cost.

The metal laser cutting equipment can directly process metal coils, realizing an integrated production line of uncoiling, leveling, feeding, cutting and unloading during the production process.

Three-chuck linkage cutting boosts your tube utilization with virtually no tailings. Three-position tube clamping plus follow-up supports ensure stable tube feeding and prevent long tubes from bending. As a result, you profit from high cutting precision, great efficiency and low material costs.

With an integrated design, no disassembly is needed for delivery, and it can be directly put into a container, saving shipping cost.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote x

Get a Quote

Get a Quote x

![]()