-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

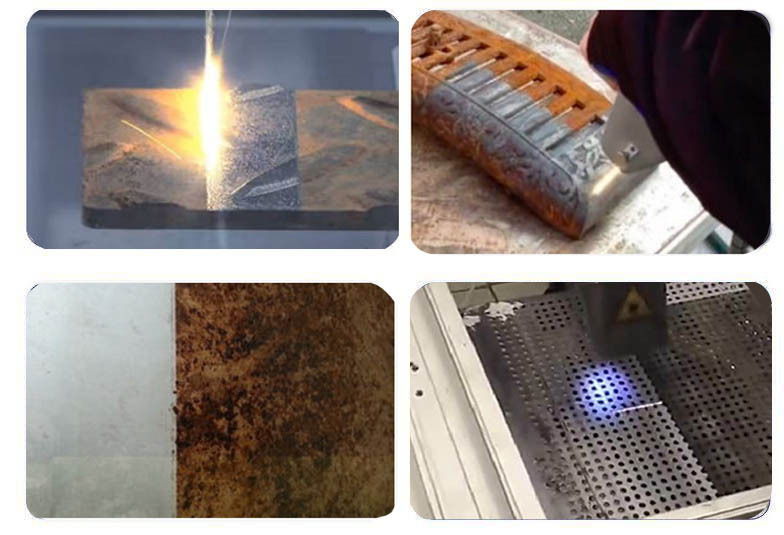

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

How to Choose the Best Fiber Laser Cleaning Machine

2024-12-10In today's competitive market, finding an efficient fiber laser cleaning machine that fits specific needs is becoming increasingly important. Fiber laser cleaning machines are favored across many industries due to their non-contact operation, high precision, and eco-friendly characteristics. However, the plethora of options on the market can be bewildering for buyers. The following key points can help you choose the most appropriate fiber laser cleaning machine.

As technology advances, more companies are dedicated to providing advanced and comprehensive solutions for customers. Among them, there is a Chinese high-tech enterprise that stands out as a leader in intelligent equipment manufacturing. This company integrates R&D, production, sales, and service, focusing on offering one-stop industrial laser solutions. Its main products include laser cutting machines, cleaning machines, and welding machines, designed to meet the diverse needs of various industries. With deep technical accumulation and innovation capabilities, this company not only provides high-quality products but also ensures premium service experiences from pre-sales consultation to after-sales support.

Determine Specific Application Needs Each industry has different cleaning requirements. For example, electronics manufacturing may need to remove tiny contaminants without damaging delicate components; automotive manufacturing might focus more on rust removal and old paint stripping. Identifying your specific application is the first step in choosing the right equipment.

Evaluate Technical Specifications

Power Output: Different power levels suit different materials and thicknesses. Ensure the chosen machine’s power range meets your work requirements.

Wavelength: Select an appropriate wavelength based on the material type to achieve optimal absorption efficiency and effect.

Cleaning Speed: Consider production pace and choose a matching cleaning speed.

Precision: For fine processing, higher positioning accuracy and repeatability are needed.

Focus on Safety and Usability Safety performance of laser equipment is critical. Look for products with built-in safety features such as protective covers and emergency stop buttons. Also, user-friendly interfaces that are easy to learn and use can improve work efficiency and reduce training time.

Consider Maintenance and Support Services Quality manufacturers usually offer comprehensive technical support and after-sales services, including installation guidance, operational training, and regular maintenance recommendations. This extends the equipment lifespan and reduces long-term operating costs.

Cost-Benefit Analysis When purchasing, consider not only the initial investment but also operating costs (such as power consumption), consumable expenses (like lens replacement), and potential repair costs. Calculate the total cost of ownership (TCO) to choose the most cost-effective option.

Brand Reputation and Customer Feedback Refer to other users' reviews and industry reputation to understand the reliability of the brand and actual product performance. A well-regarded brand often means more stable quality and better user experience.

Environmental Considerations As global attention to environmental protection increases, choosing a fiber laser cleaning machine that complies with environmental standards is also crucial. Check if the product features energy-saving designs or low emissions.

By partnering with such a one-stop supplier, you can obtain tailor-made laser technology solutions, optimizing production processes, enhancing product quality, and reducing environmental impact. In summary, when choosing a fiber laser cleaning machine, considering all the aforementioned factors will aid in making an informed decision. Careful research and comparison will help you find the ideal solution that meets current needs and allows for future expansion. We hope this guide assists you effectively during the selection process.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()