-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

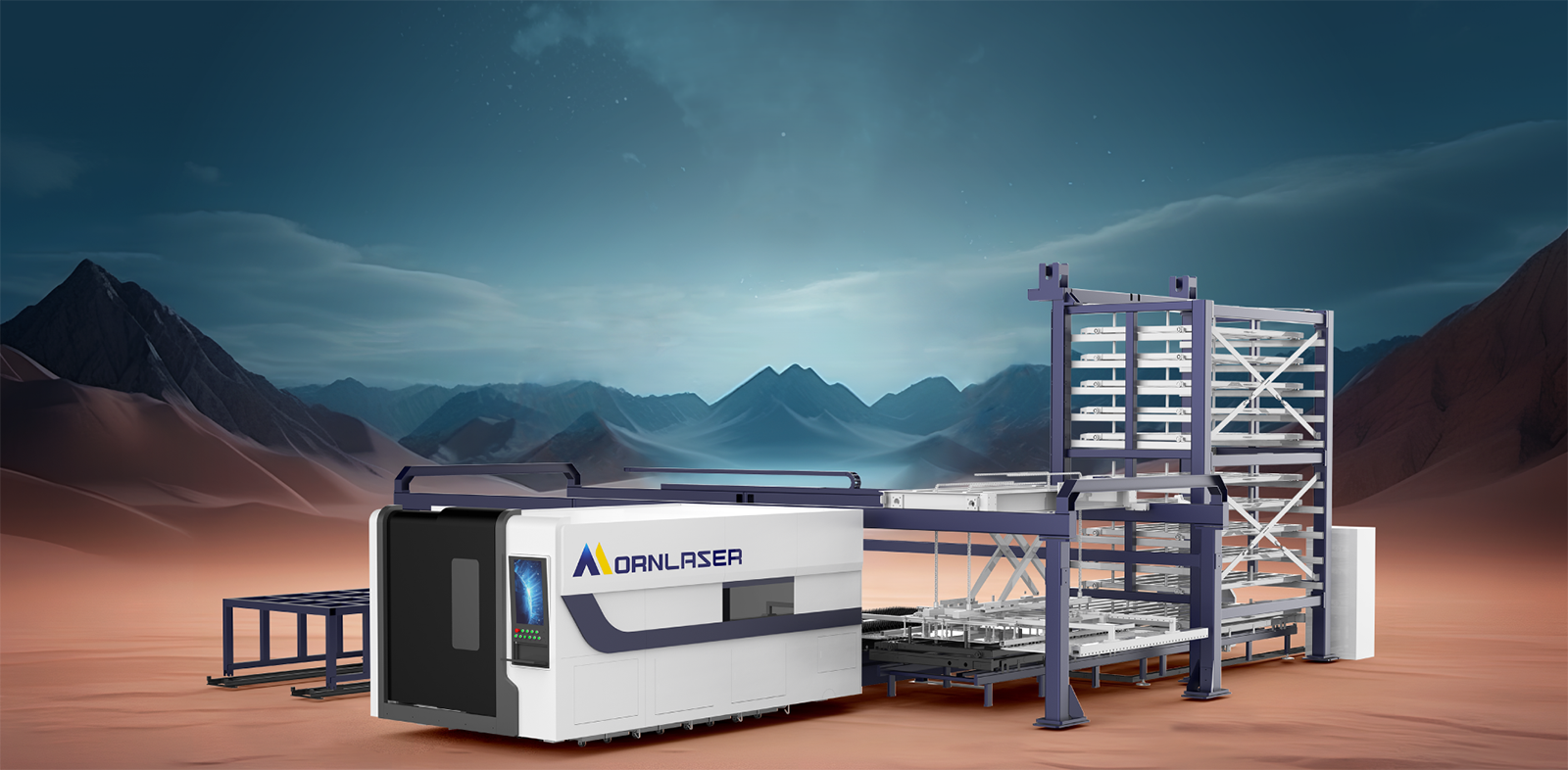

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Top 5 Questions About Coil Fed Laser Cutting Machines Answered

2024-12-23Coil-fed laser cutting machines have revolutionized the manufacturing industry, offering unparalleled precision and efficiency. However, with any advanced technology, questions often arise about its functionality, benefits, and suitability for various applications. In this article, we address the top five frequently asked questions about coil-fed laser cutting machines to help you make an informed decision.

1. What Are the Key Advantages of Using a Coil-fed Laser Cutting Machine?

One of the most significant advantages of coil-fed laser cutting machines is their ability to process materials continuously from a coil, minimizing downtime and increasing productivity. These machines also offer high-precision cuts, thanks to their advanced control systems and laser technology. Additionally, automation features such as automatic loading and unloading further enhance efficiency, reduce labor costs, and improve safety in the workplace.

2. How Does a Coil-fed Laser Cutting Machine Improve Production Efficiency?

A coil-fed laser cutting machine significantly boosts production efficiency through several mechanisms. High acceleration capabilities (up to 1.5G) and rapid linkage speeds (up to 140m/min) allow for swift material processing without sacrificing accuracy. The ability to cut thick materials, such as stainless steel up to 100mm, ensures versatility across diverse projects. Moreover, the machine’s powerful laser (up to 60,000W) can handle complex shapes and materials efficiently, reducing cycle times and improving throughput.

3. Can a Coil-fed Laser Cutting Machine Handle Various Materials?

Yes, coil-fed laser cutting machines are highly versatile and can handle a wide range of materials, including but not limited to stainless steel, aluminum, copper, and even some plastics. The adjustable laser power allows for precise cutting across different material types and thicknesses, making these machines suitable for industries like automotive, aerospace, and electronics manufacturing.

4. What Maintenance Is Required for Coil-fed Laser Cutting Machines?

Maintaining a coil-fed laser cutting machine involves regular checks and servicing to ensure optimal performance. Routine maintenance includes cleaning the lens and mirrors, inspecting the cooling system, and verifying the alignment of the laser beam. Manufacturers like MOrnlaser provide comprehensive support and maintenance services to help users keep their machines running smoothly. Proper maintenance extends the lifespan of the machine and ensures consistent cutting quality.

5. How Do I Choose the Right Coil-fed Laser Cutting Machine for My Business?

Selecting the right coil-fed laser cutting machine depends on your specific needs and production requirements. Consider factors such as the type and thickness of materials you will be cutting, desired production speed, and available space in your facility. Additionally, evaluate the machine's automation capabilities, energy efficiency, and customization options. Brands with a strong reputation, like MOrnlaser, known for its 16 years of R&D experience, can offer reliable solutions and excellent customer support.

Conclusion

Understanding the key aspects of coil-fed laser cutting machines can greatly assist in making the right choice for your manufacturing processes. By addressing common questions, this guide aims to provide valuable insights into the benefits, applications, and maintenance of these innovative machines. Whether you are looking to upgrade your existing equipment or invest in new technology, choosing the right coil-fed laser cutting machine can significantly enhance your operational efficiency and product quality.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()