-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

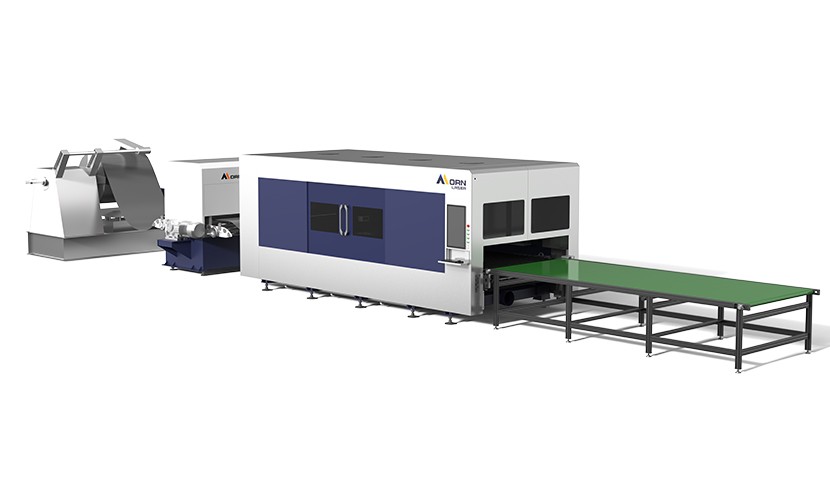

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Coil Fed vs. Sheet Laser Cutting: Which is Best for You?

2024-12-24In modern manufacturing, choosing the right material processing method is critical for ensuring product quality and enhancing production efficiency. When it comes to metal processing, manufacturers often have to choose between Coil Fed and Sheet Laser Cutting methods. Each approach has its distinct advantages and is suited to different types of projects. Let's explore these two technologies in detail to help you determine which best fits your business needs.

Coil Fed Laser Cutting

Coil Fed laser cutting is a continuous process ideal for high-volume production of standardized parts. In this method, metal is supplied to the laser cutter in coil form. Key benefits include:

High Cost-Effectiveness: Reduces material handling and preparation time, lowering piece costs.

Efficient Production Capacity: Capable of rapidly processing large orders on a continuous basis.

High Degree of Automation: Easily integrates into fully automated production lines, boosting overall efficiency.

Sheet Laser Cutting

On the other hand, Sheet Laser Cutting tends to be more suited for small batch or customized production. It involves securing metal sheets onto a worktable for individual cutting. Advantages of sheet laser cutting include:

Strong Flexibility: Perfect for handling parts with complex shapes or varying sizes.

High Precision: Achieves extremely accurate cuts, meeting high-quality standards.

Ideal for Short Production Runs: Excellent for rapid prototyping or limited production runs.

Which One Should You Choose?

Deciding on which method to use largely depends on your specific needs. If you're looking for a large-scale, low-cost, and consistent solution, then Coil Fed might be the better option. For companies seeking flexibility, precision, and quick response to market changes, Sheet Laser Cutting could be more appropriate.

Ultimately, evaluating your own requirements and considering long-term objectives is key. Partnering with professional suppliers who can recommend the optimal technical solution based on your particular situation can be invaluable. Whichever method you choose, ensure that the selected laser cutting process maximizes your business growth and meets customer expectations.

Through the above comparison analysis, we hope you gain a clearer understanding of the distinctions between Coil Fed and Sheet Laser Cutting and make an informed choice. Remember, the right processing method not only improves product quality but also brings significant cost savings and competitive advantage.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()