-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

The Wide Application and Significant Advantages of Fiber Laser Cutting Machines in Mechanical Manufacturing

2024-12-24Machinery manufacturing is the core sector of modern industry, encompassing a wide range of processes from metalworking to component manufacturing. As an efficient and high-precision processing tool, fiber laser cutting machine has become an indispensable equipment in the machinery manufacturing industry. This article will explore in detail the specific application scenarios of laser cutting machines in machinery manufacturing and their significant advantages.

Major Applications of Metal Laser Cutting Machines in Mechanical Manufacturing

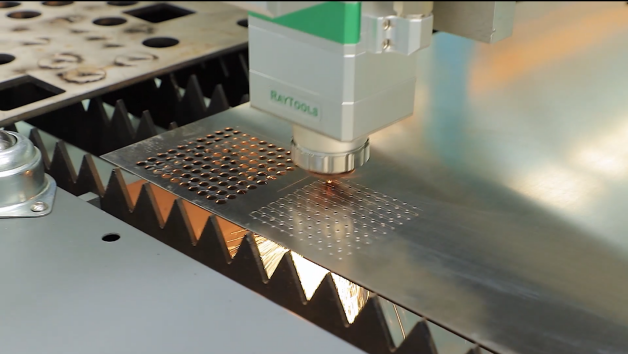

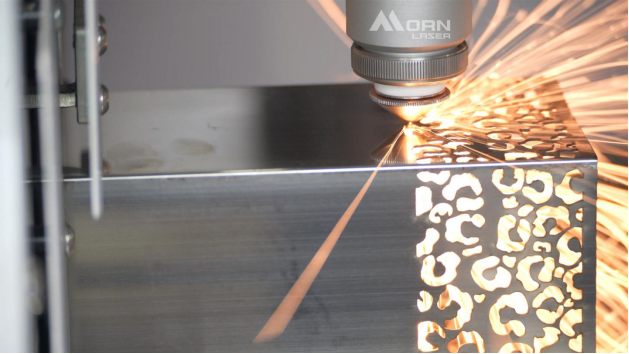

In machinery manufacturing, metal sheets and pipes are commonly used base materials. The fiber laser cutting machine, by focusing high-energy laser beams, can achieve precise cutting of metal sheets and tubes, producing smooth and burr-free edges. Compared to traditional cutting methods, laser cutting significantly improves both the cutting quality and efficiency.

The machinery manufacturing industry has increasingly higher precision requirements for components, such as precision parts used in the production of gears, bearings, molds, and more. Due to its outstanding processing accuracy, metal laser cutting machine can easily complete the cutting tasks of complex parts, meeting the high-precision demands of modern machinery manufacturing.

(https://www.youtube.com/watch?v=2gw5eLlqJrs)

Core Advantages of Fiber Laser Cutting Machines

1、Unmatched Precision and Complex Cutting Capabilities

CNC laser cutting machines is known for its extremely high precision, enabling extremely small error margins in complex cuts. Combined with advanced control systems allow for fully automated operations, reducing human error and improving product consistency.

2、High Cutting Speed

Compared to traditional cutting methods, fiber laser cutters offer significantly faster cutting speeds. Their high-speed capabilities make them ideal for mass production, effectively reducing production cycles and saving time costs for businesses.

3、Versatility Across Metal Materials

Fiber laser cutting machines can effortlessly cut various metal materials, such as carbon steel, stainless steel, and aluminum alloys. Their broad applicability opens up more possibilities for mechanical manufacturing.

4、Adaptability for Custom Production

Fiber laser cutting machines can flexibly adjust cutting parameters according to production needs, enabling rapid transitions between processing tasks for different production demands. Their high level of flexibility makes them an ideal tool for customized production.

The widespread adoption of laser cutting machines has had a profound impact on the mechanical manufacturing industry. It has not only significantly improved production efficiency and quality but also reduced manufacturing costs, enabling companies to gain a competitive edge in an increasingly demanding market. Moreover, ongoing advancements in laser cutting technology are expected to further expand its application, injecting new momentum into the intelligent and sustainable development of the mechanical manufacturing sector.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()