-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

The Future Trends of Fiber Laser Cleaning Machines

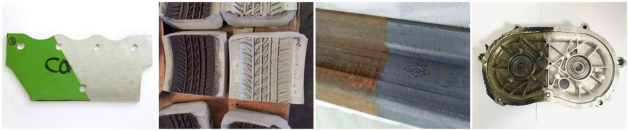

2025-01-03Laser cleaning technology, an advanced method for surface cleaning, is gradually replacing traditional techniques. With continuous technological advancements and expanding applications, laser cleaning machines have garnered widespread attention globally. This article explores the future trends of laser cleaning technology and its potential impact on the industrial cleaning sector.

Future Trends of Laser Cleaning Machines

Intelligent Development

Future laser cleaning systems will focus more on automation, incorporating features like automatic identification of contaminants and self-adjusting laser power, making operations simpler and adaptable to various cleaning needs.Enhanced Power and Efficiency

As laser technology evolves, laser cleaning machines will offer higher power output, significantly improving cleaning efficiency. High-power laser cleaning machines will handle larger-scale tasks, reducing cleaning time.Multifunctional Integration

Future laser cleaning equipment may integrate additional functions, such as laser cutting or laser welding, creating versatile machines that can meet multiple industrial demands, further increasing the value of laser cleaning technology.Wider Industry Applications

Laser cleaning technology will continue to expand into more industries, particularly high-precision industries like semiconductor manufacturing and aerospace. These industries demand top-tier cleaning quality, which laser cleaning can provide.Ongoing Environmental Focus

With stricter global environmental regulations, laser cleaning machines will remain a preferred choice due to their eco-friendly nature. Future models will further enhance energy efficiency and minimize waste generation.Miniaturization and Portability

Laser cleaning machines will become smaller and more portable, offering increased flexibility and convenience, especially for precision cleaning and on-site tasks in mobile laser cleaning applications.

Conclusion

Laser cleaning machines will continue to show great potential for growth in the future. With advancements in automation, environmental sustainability, and efficiency, laser cleaning technology will play an increasingly crucial role across industries. To stay competitive, businesses should embrace these trends, invest in advanced laser cleaning equipment, and enhance both production efficiency and product quality, contributing to their long-term sustainability.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()