-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

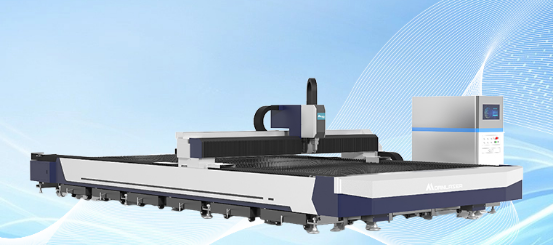

Breaking Traditional Limits: A Newly Designed Separated Working Bed with Both High Speed and Heavy Load Capacity

2025-03-11To further enhance the long-term stability of the laser cutting machine, we have adopted a non-load-bearing, hollow separated-bed design. This innovative approach optimizes durability and precision retention in several key ways:

- Independent Working table Load-Bearing: Traditional machines rely on the entire working bed for load support, whereas our design features an independent inner worktable that supports the metal plates weight. The outer bed carries only the beam, significantly reducing structural stress and minimizing deformation risks.

- Separation of Load-Bearing and Motion: The inner worktable primarily supports the metal plates weight, while the beam moves independently on the outer bed. This separation ensures that even after prolonged high-speed operation, the laser cutter machine maintains exceptional precision.

- Heat Transfer Isolation: During high-power laser cutting, intense heat and the weight of the plates can cause bed deformation, leading to reduced processing accuracy. Our new bed structure effectively isolates heat transfer, ensuring stable cutting precision even after prolonged operation.

- Enhanced Working Bed Durability: With a scientifically optimized load distribution, the machine is better equipped to withstand long-term high-load operation, minimizing deformation and maintaining high precision over time. This reduces accuracy loss caused by bed deformation, ensuring consistent performance.

In daily operations, maintenance costs and upgradeability are key concerns for businesses. Our separated bed laser cutting machine features an optimized structural design that ensures easier maintenance and lower costs:

Arched “Bridge-Type” Blade Structure:

Both ends are connected to the inner bed, with reserved gaps between the inner bed’s ribs and the blades. This allows for controlled deformation space, further protecting both the inner and outer bed.

Upgrades Require Only Working table (Inner Bed) and Blade Replacement:

In traditional laser cutting machines, prolonged operation leads to wear on the blades and working table, making full machine replacement costly. Our design allows for easy replacement of just the inner bed and blades, significantly reducing upgrade expenses.

Our laser cutting equipment allows for independent replacement of the blades and worktable, eliminating the need to replace the entire bed. This design significantly reduces maintenance and replacement costs while enhancing the machine’s long-term value.

Additionally, through extensive testing, we have optimized the bed’s height to align with ergonomic principles, ensuring greater user comfort. The segmented exhaust system, which blows from one side and extracts from the other, effectively maintains a clean working environment.

As a one-stop industrial laser solution provider, Morn Laser has become the trusted choice of tens of thousands of customers around the world with its cutting-edge production technology, reliable service and commitment to product lifetime responsibility. In the future, we will continue to uphold the spirit of craftsmanship, continuously pursue excellent quality, and strive to become a powerful engine for the the upgrading of the old drivers of growth industrial intelligent equipment industry.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()