-

Product

-

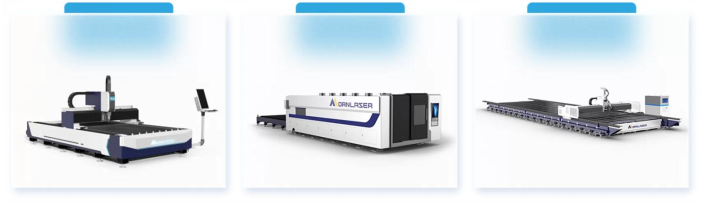

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Surging Demand for Thick Plate Cutting: Fiber Laser Cutting Machine Becomes Industry Standard

2025-04-25As demand for medium and thick metal plate processing continues to grow in industries such as construction machinery, steel structures, shipbuilding, and rail transportation, the drawbacks of traditional cutting methods like flame cutting and plasma cutting are becoming increasingly apparent. With its advantages of high cutting efficiency, excellent precision, small cutting seam, and small heat-affected zone, high power fiber laser cutting machine is rapidly replacing the old process, becoming the new standard in the field of medium and thick plate processing.

Why is laser cutting favored for thick plate processing?

1. Stable Cutting Quality: Smooth and clean cutting edges, and no secondary processing is required.

2. Small Thermal Deformation: Narrow heat-affected zone, ideal for cutting high-precision structural components.

3. High Piercing Efficiency: High power metal laser cutter allows for faster piercing, significantly improving cutting speed.

4. Multi-material Adaptation: Easily handles carbon steel, stainless steel, alloy steel, aluminum plates, and other thick metal materials.

5. Remote Control & Smart Nesting Support: Improves material utilization and reduces operation costs.

Especially in the cutting of 16mm, 20mm, 25mm, 30mm, and even up to 50mm thick plates, high-power metal laser cutting machines (12kw, 20kw, 30kw and above) demonstrate unmatched advantages over traditional cutting methods.

As manufacturing industries accelerate equipment upgrades, the medium and thick plate market has a particularly strong demand for the following types of laser cutting equipment:

1. Single-Table Laser Cutting Machine (12kw–60kw): Ideal for cutting thick carbon steel and stainless steel materials.

2. Full Enclosed Laser Cutting Machine: Safer and more environmentally friendly, suitable for high-frequency and large-volume processing tasks.

3. Large-Format Laser Cutting Machine: customizable large-size cutting areas, serving the bridge, ship and steel structure industries.

In line with the global trends of green manufacturing and energy efficiency, fiber laser cutting machines for thick plates are becoming core productivity tools in industries like steel structures, machinery, and shipyards. Medium and thick metal plate laser cutting is not just a technological upgrade—it’s a revolution in productivity and cost control.

To meet the processing needs of medium and thick plates, we offer a range of high-power laser cutting machine models tailored to companies of all sizes—covering everything from standard cutting to high-speed cutting of ultra-thick materials.

Contact us today to get more detailed information of laser cutting solutions!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()