-

Product

-

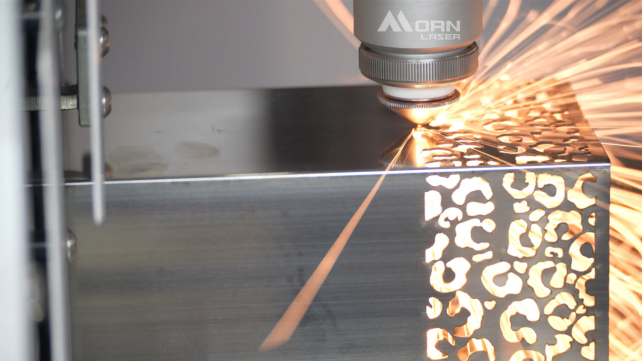

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Tube Laser Cutting Machines: Why You Need One for Metal Fabrication

2025-06-05Why Traditional Pipe Cutting No Longer Works

If you're still using manual saws, drills, or traditional cutting lines to process metal tubes and pipes, you're likely dealing with:

× Low precision and rough edges

× Time-consuming measuring and setup

× High labor costs

× Limited productivity when dealing with complex profiles

As customer demands for customized, fast, and precise tube fabrication increase, more manufacturers are turning to tube laser cutting machines—especially in industries like furniture, automotive, gym equipment, and structural steel.

What Is a Tube Laser Cutting Machine?

A tube laser cutter is a CNC-controlled system that uses a laser source to cut round, square, rectangular, oval, and even special-shaped pipes with incredible precision and speed.

Modern models come with:

High-precision pneumatic chucks

Auto-loading and unloading features

Ability to pierce, bevel, and contour cut in one go

Some Applications of Tube Laser Cutting

Furniture: Table/chair frames, shelf supports

Fitness Equipment: Dumbbell racks, crossfit frames, gym machines

Agricultural Machinery: Tube frames, hydraulic pipe assemblies

Construction: Steel frames, scaffolding pipes, support beams

Automotive: Exhaust tubes, chassis structures, seat frames

Key Benefits Over Traditional Cutting Methods

- High Precision, No Post-processing Needed

Laser cutting ensures ultra-clean edges with tolerance as low as ±0.05mm, eliminating grinding or secondary machining.

- Speed + Flexibility

Easily switch between different diameters and thicknesses without manual setup. Ideal for high-mix low-volume production.

- Complex Geometry Made Simple

Cut slots, holes, notches, bevels, and angles in a single pass—no need for separate drilling or milling.

- Reduced Labor Costs

Automatic material feeding and unloading reduce operator workload. One person can manage multiple machines.

- Better Material Utilization

With intelligent nesting software, you can minimize waste and improve cutting yields.

If your workflow includes both metal sheets and pipes, consider a dual-use model (plate & tube laser cutting machine).

What to Look For in a Tube Laser Cutting Machine

Clamp range & chuck design

Supported pipe types & max length

Laser source brand

Optional bevel cutting

Automation level (semi or full-auto loading)

Why Choose Morn Laser for Tube Cutting Solutions?

Tube-specific models from 1kW to 12kW+

Supports pipe diameters from 20mm to 350mm

Auto centering & clamp adjustment for fast setups

Customizable for auto-loading, and bevel cutting

Serving 155+ countries and regions with fast delivery

CE, FDA, ISO certified

Whether you process round pipes, rectangular tubes, or custom profiles, Morn Laser's tube cutting systems are built for speed, precision, and scalability.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()