-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

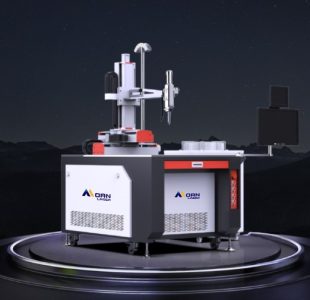

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Laser Welding Stainless Steel Sink

2022-12-29Stainless steel sinks have become an indispensable part of modern kitchens, prized for their durability, hygiene, and sleek appearance. However, traditional welding methods used to manufacture these sinks often fall short — resulting in unsightly weld seams, leaks, significant deformation, and time-consuming post-processing.

The Limitations of Traditional Welding

Conventional methods like argon arc welding have long been the standard for stainless steel sink fabrication. Yet, these approaches bring challenges: excessive heat causes material warping, weld seams are rough and prone to leakage, and polishing labor is intensive — all contributing to higher costs and lower product quality.

How Laser Welding Solves These Problems

Since 2016, MORN LASER has developed specialized laser welding machines designed to overcome these issues. Laser welding offers several distinct advantages:

Low Heat Input: Minimizes deformation, preserving sink shape and integrity.

Smooth, Leak-proof Welds: Produces clean, flat weld seams without the need for fillers or solder, avoiding lead contamination.

Reduced Post-Processing: Laser welding’s precision greatly decreases polishing and finishing work, saving labor and time.

Improved Efficiency and Quality: Faster welding speeds and lower scrap rates help manufacturers meet increasing production demands.

These benefits make laser welding the ideal choice for producing high-quality stainless steel sinks that are both durable and visually appealing.

Backed by Strong R&D and Manufacturing Capabilities

MORN LASER’s commitment to innovation is reflected in its strong R&D foundation and manufacturing scale. With dedicated teams investing over 10% of annual revenue into research and development, the company continuously improves laser welding technology to meet evolving market needs.

Our state-of-the-art production base and global service network ensure reliable delivery and support, helping customers worldwide achieve higher competitiveness with advanced laser welding solutions.

Experience the Difference Today

Laser welding technology is transforming stainless steel sink manufacturing — enhancing product quality while cutting costs and labor. If you’re interested in upgrading your welding processes, we invite you to explore MORN LASER’s laser welding machines tailored for stainless steel sinks.

For more details and to request a free sample weld or factory visit, please visit our product page or contact us directly.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()