-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Why Can Laser Cleaning Machine Clean the Surface Stains of the Workpiece?

2022-08-19Maybe someone have this doubt: Laser cleaning machine only uses a beam of light. Why can it remove rust? the article will show you the reason.

When the workpiece is placed for a long time, it is inevitable that some stains will accumulate. Metal products are placed in a humid place or exposed to the air, which will cause oxidation reaction, and then rust will appear. If you want to use it again, you need to first clean the surface of the workpiece. To remove the rust, industrial machinery will use laser cleaning to remove rust.

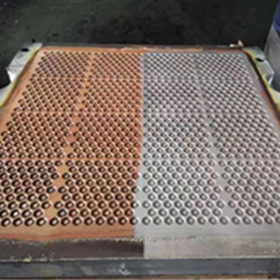

(laser cleaning sample show)

The laser source is composed of three parts: working substance, excitation source and optical resonator. After the oscillation and amplification of the gain medium in the optical resonator, a laser is formed. The light with sufficient functions is focused in the same place and irradiated to the appropriate part of the material. Perform surface heat treatment on the irradiated material, and the light beam emitted by the laser is absorbed by the pollution layer on the surface, so as to achieve the purpose of removing the adsorption rust layer from the surface of the object and achieving the purpose of cleaning.

Laser cleaning machine can not only remove the rust on the metal, but also remove the coating, paint layer, oxide layer, plating layer, etc. Compared with traditional cleaning, laser cleaning machine has many advantages. Laser cleaning machine is environmentally friendly. This feature is a feature that traditional cleaning does not have. The shortcomings of traditional cleaning methods have prompted the application of laser technology in the field of surface cleaning. Due to its many advantages, laser cleaning machine is now the most effective method for removing unwanted substances from the surface of materials.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()