-

Product

-

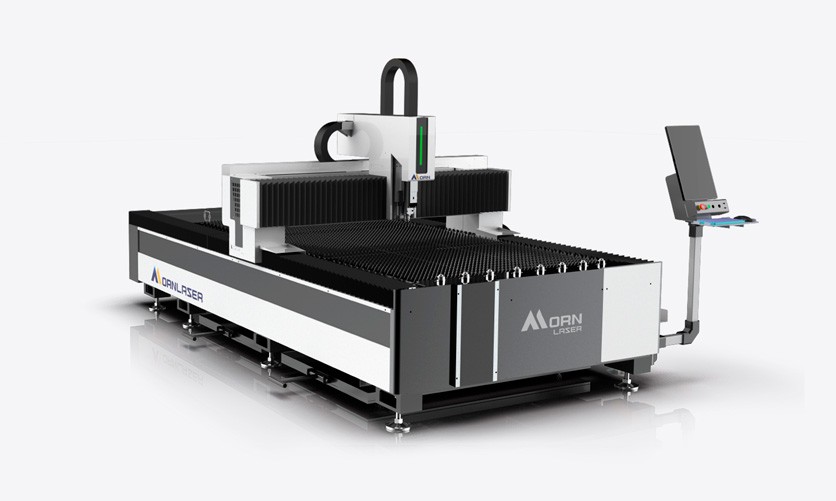

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

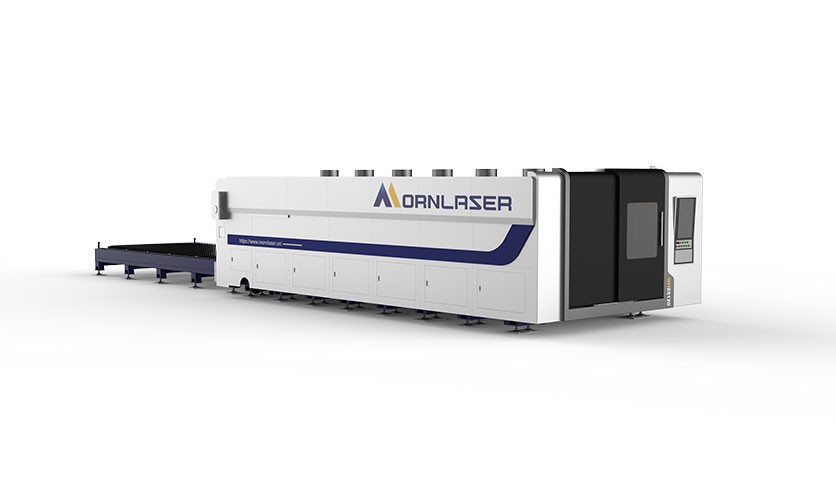

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

How to choose the right fiber laser cutting machine according to your needs

2024-09-10In the relentless pursuit of efficiency and precision in manufacturing, selecting the right fiber laser cutting machine is paramount. Amidst the myriad of options in the market, a thorough analysis of critical factors is essential to ensure a perfect match for your business requirements. This meticulously crafted guide aims to empower you with insights for a wise and forward-thinking decision.

I. Clearly Define Your Cutting Needs

Start by pinpointing the materials you intend to process and their specific properties. Fiber laser cutting machines excel in metalworking, encompassing stainless steel, aluminum, mild steel, copper, and more. Also, consider the material thickness range, as it significantly influences your choice. For handling large diameters or thick materials, ensure the selected machine boasts ample cutting capacity and stability.

II. Assess Production Demands and Efficiency

Production volume dictates the configuration of your cutting machine. High-volume requirements call for machines with high-speed cutting capabilities and impressive acceleration rates. Look for models capable of achieving rapid cutting speeds like 130m/min, coupled with outstanding acceleration performance, to bolster your productivity.

III. Balancing Laser Power with Cutting Performance

Laser power is directly proportional to cutting speed and material processing capabilities. For frequent processing of thick materials, opt for machines with high laser power outputs, such as 6000W or above. This configuration ensures efficient and precise cutting across various material thicknesses.

IV. Emphasizing Machine Design and User-Friendly Features

Ease of use and maintenance are non-negotiable qualities in modern industrial equipment. Consider machines with dual chucks or similar convenient loading mechanisms to enhance material handling continuity and efficiency. User-friendly control interfaces and intuitive operating systems streamline workflows, minimizing human errors and downtime.

V. Strengthening Safety and Environmental Standards

Safety remains paramount in industrial settings. Ensure your fiber laser cutting machine is equipped with comprehensive safety features, like fully enclosed guards, to safeguard operators from potential hazards. Additionally, prioritize dust and fume extraction systems that adhere to environmental standards, fostering a clean and safe working environment.

VI. Considering Integration Capabilities and Future Scalability

As your business evolves, production needs may shift. Select a fiber laser cutting machine with integration capabilities and room for expansion. A machine that seamlessly integrates into your existing production line and offers upgrade potential supports your long-term growth.

VII. Evaluating Manufacturer Strength and After-Sales Service

Choosing a reputable and capable manufacturer is vital for device quality and post-sales support. Investigate the manufacturer's industry experience, technical prowess, and customer feedback to make an informed choice. Top-notch after-sales service and maintenance support ensure your machine operates optimally, minimizing downtime risks.

VIII. Comprehensive Cost-Benefit Analysis

Before finalizing your decision, comprehensively assess the cost versus benefits. High-performance machines may entail steeper initial investments but often yield substantial long-term gains, including productivity boosts, reduced labor costs, and waste minimization. Conduct a thorough cost-benefit analysis to ensure your selected machine maximizes value for your enterprise.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()