-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

What can fiber laser cleaning machine clean? Quick Guide

2024-11-07Fiber Laser Cleaning Machine: Easily Tackle Various Cleaning Challenges

Hello everyone! Today we're going to talk about a super practical cleaning tool—the fiber laser cleaning machine. You might have heard of laser cutting or laser marking, but did you know that lasers can also be used for cleaning? Yes, a fiber laser cleaning machine can not only remove stubborn stains but also protect your equipment from damage. Let's take a look at what it can clean!

1. Metal Surfaces

Whether it's steel, aluminum, copper, or other alloys, rust, oil stains, paint, and oxidation layers can be a real headache. A fiber laser cleaning machine can easily remove these stubborn stains without damaging the metal surface, making it perfect for cleaning precision parts. Imagine your metal components looking brand new, boosting your work efficiency!

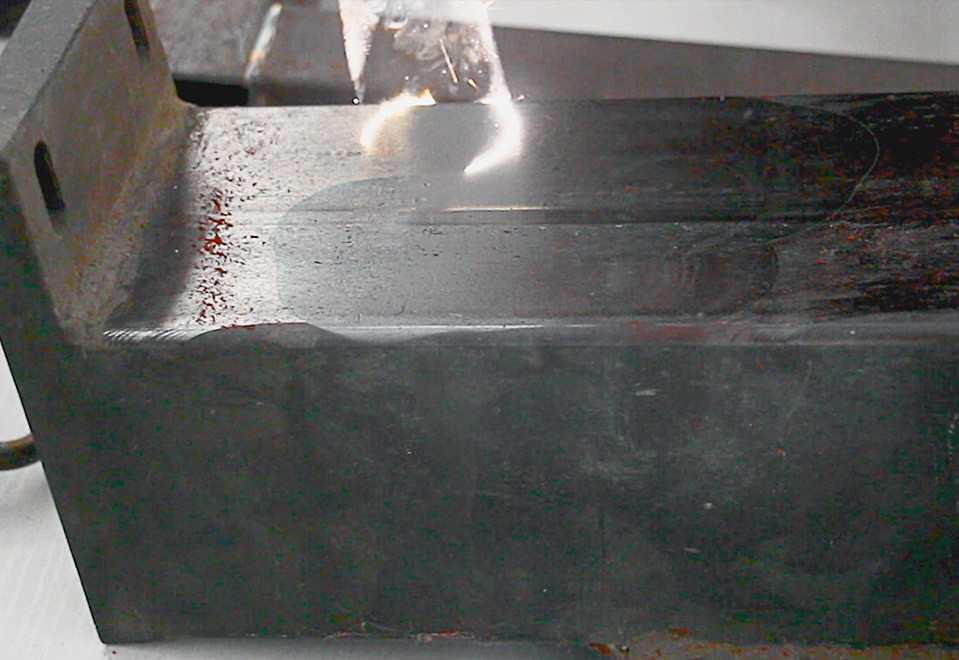

2. Molds

Molds often accumulate dirt and residues during production. Traditional cleaning methods are time-consuming and can damage the molds. With a fiber laser cleaning machine, you can precisely remove dirt from the mold surface, extending its lifespan and improving production efficiency, saving you both time and effort.

3. Electronic Components

Electronic components require a very high level of cleanliness, and traditional chemical cleaning methods can leave harmful residues. A fiber laser cleaning machine is completely non-contact and non-polluting, thoroughly removing dust and dirt from electronic components to ensure the performance and reliability of circuit boards. This is crucial for electronic products.

4. Automotive Parts

The cleanliness of automotive parts directly affects the quality of the entire vehicle. A fiber laser cleaning machine can easily remove oil sludge and carbon deposits from key components like engine blocks and piston rings, ensuring the performance and longevity of your vehicle, making it look brand new again.

5. Aerospace Parts

Aerospace parts have extremely high cleanliness requirements, and even the smallest amount of dirt can lead to serious consequences. A fiber laser cleaning machine can precisely control the cleaning area, ensuring every detail meets the highest standards, making your aircraft safer and more reliable.

6. Cultural Heritage Restoration

Laser cleaning machines are not just for industrial use; they can also be used for cultural heritage restoration. A fiber laser cleaning machine can gently remove dirt from the surface of artifacts without damaging them, helping us preserve historical and cultural treasures.

7. Medical Equipment

The cleanliness of medical equipment is crucial for patient safety. A fiber laser cleaning machine can thoroughly remove bacteria and viruses from surgical instruments and medical devices, ensuring their hygiene and safety, giving you peace of mind.

Why Choose a Fiber Laser Cleaning Machine?

Efficient and Fast: Laser cleaning is quick and efficient, significantly reducing cleaning time and making your work more productive.

Non-Destructive Cleaning: Laser cleaning does not damage the surface of the object being cleaned, making it ideal for precision parts and valuable items, keeping your equipment in pristine condition.

Environmentally Friendly: Laser cleaning does not require chemical agents, producing no harmful substances and being very eco-friendly.

Precise Control: Laser cleaning can precisely control the cleaning area and depth, suitable for objects of various complex shapes, making your cleaning work more precise.

Conclusion

A fiber laser cleaning machine is a highly practical cleaning tool that can benefit anyone, whether you're a professional in the industrial sector or an expert in cultural heritage preservation. For example, Morn Laser is a company with 17 years of experience in this field. Their fiber laser cleaning machines are not only technologically advanced but also offer reliable service and lifetime support, helping countless customers around the world solve various metal processing challenges.

We hope this article helps you better understand the applications and advantages of fiber laser cleaning machines. If you have any questions or need more information, feel free to leave a comment and engage in the discussion!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()