-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

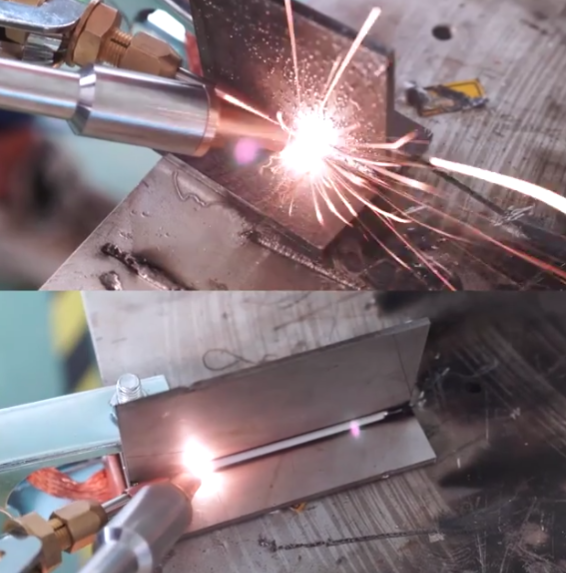

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Common Questions About Fiber Laser Welding Machines

2024-11-08Hello everyone! Today, we’re going to address some common questions about fiber laser welding machines. If you’re interested in this high-tech equipment or are considering purchasing one, these questions and answers might be very helpful. Let's take Morn Laser as an example. Founded in 2008, Morn Laser is a comprehensive high-tech enterprise specializing in the research, development, production, sales, and service of intelligent manufacturing equipment. As a one-stop industrial laser solution provider, Morn Laser has become the preferred laser brand for tens of thousands of customers worldwide, thanks to its cutting-edge technology, reliable service, and commitment to lifetime product support.

1. What Materials Can Fiber Laser Welding Machines Weld?

Fiber laser welding machines can weld almost all types of metal materials, including stainless steel, carbon steel, aluminum alloys, and copper alloys. They are particularly suitable for thin plates and precision components because the laser beam can precisely control the welding area, avoiding thermal effects on surrounding materials.

2. How Fast Are Fiber Laser Welding Machines?

Fiber laser welding machines are very fast. Compared to traditional welding methods like arc welding or resistance welding, fiber laser welding machines can complete welding tasks in just a few seconds. This not only increases production efficiency but also reduces the workload on workers.

3. Is Maintenance of Fiber Laser Welding Machines Difficult?

Maintaining a fiber laser welding machine is relatively simple. Mainly, you need to keep the laser head and lens clean, regularly check the cooling system and filters to ensure they are functioning properly. Additionally, follow the manufacturer's recommendations for replacing consumables such as filters and cooling liquids to extend the machine's lifespan.

4. How Safe Are Fiber Laser Welding Machines?

Fiber laser welding machines are very safe, but it’s important to follow basic safety guidelines during operation. For example, wear protective glasses to avoid direct exposure to the laser beam, ensure good ventilation in the work area to prevent the accumulation of harmful gases, and regularly inspect safety devices to ensure they are in good condition.

5. What Is the Price Range of Fiber Laser Welding Machines?

The price of fiber laser welding machines varies depending on the brand, model, and features. Generally, entry-level fiber laser welding machines are more affordable and suitable for small businesses and individual workshops. High-end models are more expensive but offer superior performance and are ideal for large enterprises and high-precision welding needs.

6. What Is the Quality of Welds from Fiber Laser Welding Machines?

The quality of welds produced by fiber laser welding machines is very high. The laser beam can precisely control the depth and width of the weld, ensuring uniform and aesthetically pleasing seams. Additionally, the low heat generation during the laser welding process helps prevent material deformation and thermal effects, ensuring the stability and strength of the welded structure.

7. In Which Industries Are Fiber Laser Welding Machines Used?

Fiber laser welding machines are widely used in various industries, including:

Automotive Manufacturing: For welding car bodies and components.

Aerospace: For precise welding of aircraft components.

Electronics: For welding circuit boards and micro-components.

Medical Devices: For sterile welding of medical equipment.

Jewelry: For fine welding of intricate jewelry pieces.

8. How Easy Are Fiber Laser Welding Machines to Use?

Fiber laser welding machines are relatively easy to use, especially modern ones that come with user-friendly interfaces and intelligent control systems. Even beginners can quickly get started with some simple training. However, for more complex welding tasks, it’s recommended to have experienced technicians operate the machine.

9. Are Fiber Laser Welding Machines Energy-Efficient?

Fiber laser welding machines are relatively energy-efficient. Compared to traditional welding methods, they consume less energy, which helps reduce costs and aligns with eco-friendly practices.

10. What Is the After-Sales Service Like for Fiber Laser Welding Machines?

Choosing a reputable brand and supplier is crucial because good after-sales service ensures that any issues you encounter during use are promptly resolved. Morn Laser offers comprehensive technical support and warranty services, ensuring users have a hassle-free experience. Their professional team is always ready to answer your questions and provide technical assistance.

Conclusion

We hope these answers to common questions about fiber laser welding machines have provided you with a better understanding. If you have any further questions or need more advice, feel free to leave a comment and join the discussion. Don’t forget to share this article with your friends!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()