-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

What Materials Can a Fiber Laser Welding Machine Weld?

2024-11-08Hello everyone! Today, we're going to discuss what materials a fiber laser welding machine can weld. Fiber laser welding machines are highly efficient welding devices used in various industries. Understanding the types of materials they can weld can help you better choose and use this advanced equipment. Let's take Morn Laser as an example. Founded in 2008, Morn Laser is a comprehensive high-tech enterprise specializing in research, development, production, sales, and service of intelligent manufacturing equipment. As a one-stop industrial laser solution provider, Morn Laser has gained the trust of tens of thousands of global customers with its advanced production technology and reliable service.

1. Stainless Steel

Stainless steel is one of the most common materials used with fiber laser welding machines. These machines can easily weld stainless steel sheets of different thicknesses, ensuring uniform and aesthetically pleasing welds. The heat generated during the laser welding process is minimal, effectively preventing material deformation and heat-affected zones, maintaining the structural stability and strength of the weld.

2. Carbon Steel

Carbon steel is another frequently used material with fiber laser welding machines. Whether it's thin or thick sheets, fiber laser welding machines can provide high-quality welding results. Laser welding allows for precise control of welding depth and width, ensuring uniform and stable welds. Additionally, the reduced spatter during the laser welding process minimizes post-welding treatment.

3. Aluminum Alloys

Welding aluminum alloys has always been a challenge, but fiber laser welding machines excel in this area. Aluminum has high thermal conductivity and reflectivity, making it prone to porosity and cracking with traditional welding methods. Fiber laser welding machines overcome these issues by precisely controlling laser energy and welding speed, ensuring high-quality and strong welds.

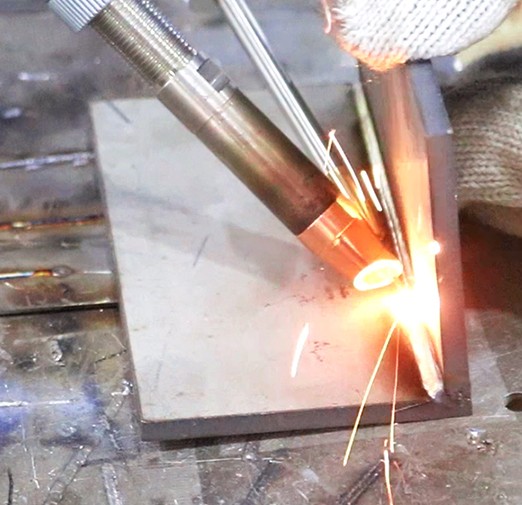

4. Copper Alloys

Welding copper alloys is also challenging due to their high thermal conductivity and reflectivity. Fiber laser welding machines use high-density laser beams to rapidly melt copper materials, forming stable welds. The concentrated heat during the laser welding process effectively reduces heat-affected zones, preventing material deformation.

5. Titanium Alloys

Titanium alloys are known for their high strength and corrosion resistance, making them widely used in aerospace and medical fields. Fiber laser welding machines can provide high-quality titanium alloy welding, ensuring uniform and stable welds. The minimal heat generated during the laser welding process helps prevent material deformation and heat-affected zones.

6. Nickel Alloys

Nickel alloys are commonly used in high-temperature and corrosive environments. Fiber laser welding machines can provide high-quality nickel alloy welding, ensuring uniform and stable welds. The concentrated heat during the laser welding process effectively reduces heat-affected zones, preventing material deformation.

7. Precious Metals

Fiber laser welding machines are also suitable for welding precious metals such as gold, silver, and platinum. These materials are often used in jewelry and precision electronic components. Fiber laser welding machines can provide precise welding results, ensuring the beauty and stability of the welds.

8. Composite Materials

In addition to single materials, fiber laser welding machines can also weld composite materials. For example, stainless steel and aluminum composites are useful in certain applications. Fiber laser welding machines can achieve high-quality welds in composite materials by precisely controlling laser energy and welding speed.

Technical Details

Laser Energy Control

Fiber laser welding machines can precisely control laser energy to meet the welding requirements of different materials. The adjustable laser energy range is broad, from a few watts to several kilowatts, ensuring flexibility and adaptability in the welding process.

Welding Speed

Fiber laser welding machines have a very fast welding speed, typically completing welding tasks in just a few seconds. High-speed welding not only increases production efficiency but also reduces the workload on workers.

Heat-Affected Zone

The heat generated during the laser welding process is concentrated, effectively reducing the heat-affected zone and preventing material deformation and performance degradation. This is particularly important for thin plates and precision components.

Non-Contact Welding

Fiber laser welding machines use a non-contact welding method, where the laser beam does not physically touch the material surface. This method is particularly suitable for precision components and fragile materials, ensuring the integrity and quality of the surface.

Why Choose Morn Laser?

Founded in 2008, Morn Laser has been dedicated to the research and production of high-quality fiber laser welding machines. As a one-stop industrial laser solution provider, Morn Laser offers the following advantages:

Advanced Production Technology: Morn Laser uses the latest production technologies and equipment to ensure the high performance and reliability of each machine.

Reliable Service: Morn Laser provides comprehensive technical support and after-sales service, ensuring that any issues customers encounter during use are promptly resolved.

Conclusion

Fiber laser welding machines can weld a variety of materials, including stainless steel, carbon steel, aluminum alloys, copper alloys, titanium alloys, nickel alloys, precious metals, and composite materials. By precisely controlling laser energy, welding speed, and heat-affected zones, fiber laser welding machines can provide high-quality welding results, meeting the needs of different industries. We hope this article has been helpful! If you have any questions or need more advice, feel free to leave a comment and join the discussion. Don't forget to share this article with your friends!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()