-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

What is a fiber laser cutting machine and what is its working principle?

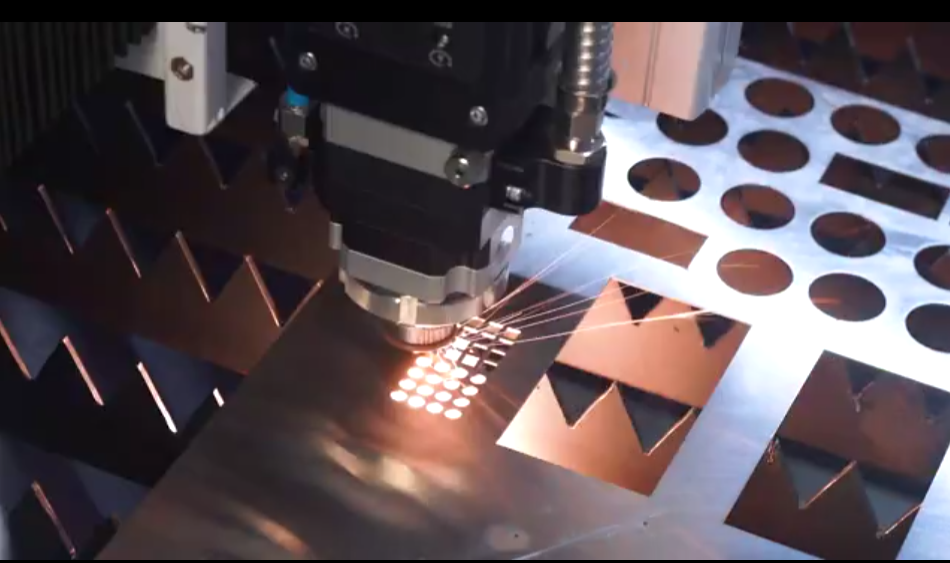

2024-11-13A fiber laser cutting machine is a high-precision cutting device that uses a fiber laser as the light source. It focuses a high-energy-density laser beam onto the surface of the material, causing the material to rapidly melt or vaporize, thus achieving precise cutting. Fiber laser cutting machines are widely used for processing metal sheets, pipes, and other materials, particularly in industries such as automotive manufacturing, aerospace, electronics, and precision instruments.

How Does a Fiber Laser Cutting Machine Work?

The working principle of a fiber laser cutting machine involves several key steps:

Laser Generation

Fiber Laser: The core component of a fiber laser cutting machine is the fiber laser, which generates laser light by doping rare earth elements into the fiber and absorbing pump light (usually provided by semiconductor lasers). Fiber lasers offer high efficiency, long life, and low maintenance costs.

Laser Transmission

Fiber Optics: The generated laser is transmitted to the cutting head via a fiber optic system. This system provides long transmission distances, excellent beam quality, and eliminates the need for optical alignment.

Laser Focusing

Focusing Lens: The laser beam is focused onto the surface of the workpiece through a focusing lens. Typically, this lens system consists of one or more lenses that can focus the laser beam to a very small spot diameter (usually less than 0.1 millimeters).

Material Melting and Vaporization

High Energy Density: The focused laser beam generates extremely high energy density at the focal point, causing the material to rapidly reach its melting or boiling point. The material then melts or vaporizes, forming a small hole.

Gas Blowing

High-Pressure Gas: Simultaneously with the laser beam, high-pressure gas (usually nitrogen, oxygen, or compressed air) is blown through a nozzle onto the cutting area, removing the melted or vaporized material and creating a clean cut.

CNC System Control

CNC System: A fiber laser cutting machine is equipped with an advanced CNC system that controls the movement path and speed of the cutting head, ensuring cutting accuracy and efficiency. The CNC system can automatically adjust the position of the cutting head and the laser power based on pre-set cutting paths and parameters.

Cooling System

Cooling System: During the cutting process, a significant amount of heat is generated. The cooling system circulates coolant to cool the laser, cutting head, and other critical components, ensuring the stable operation of the machine.

Advantages

High Precision: Fiber laser cutting machines offer high cutting precision, narrow kerf widths, smooth edges, and no burrs.

High Speed: Laser cutting is fast, leading to high production efficiency.

Low Heat-Affected Zone: The heat-affected zone during cutting is small, resulting in minimal material deformation and no mechanical stress.

Versatility: They can process a wide range of materials, including metals, plastics, glass, and ceramics.

High Automation: The combination of CNC systems and automated equipment achieves high-precision and high-efficiency automated production.

Application Fields

Fiber laser cutting machines are widely used in the following fields:

Automotive Manufacturing: Body components, exhaust systems, etc.

Aerospace: Aircraft components, engine blades, etc.

Electronics: Circuit boards, enclosures, etc.

Precision Instruments: Medical devices, optical instruments, etc.

Metal Processing: Sheet metal processing, pipe cutting, etc.

Morn Lase: Professional Laser Solutions Provider

Founded in 2008, Morn Lase is a Chinese high-tech enterprise that integrates R&D, production, sales, and service into a comprehensive smart equipment manufacturing company. As a one-stop industrial laser solutions provider, Morn Lase leverages cutting-edge production technology, reliable service, and a commitment to lifetime product responsibility to become the preferred laser brand for tens of thousands of global customers. Morn Lase continuously innovates, dedicated to providing customers with efficient, precise, and environmentally friendly laser cutting solutions.

Conclusion

Fiber laser cutting machines, with their high efficiency, precision, and flexibility, are indispensable in modern manufacturing. Understanding their working principles can help users better leverage the advantages of fiber laser cutting machines to improve production efficiency and product quality. If you have any questions or need further assistance, feel free to contact Morn Lase. We are committed to providing you with the highest quality products and services to help you excel in a competitive market.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()