-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

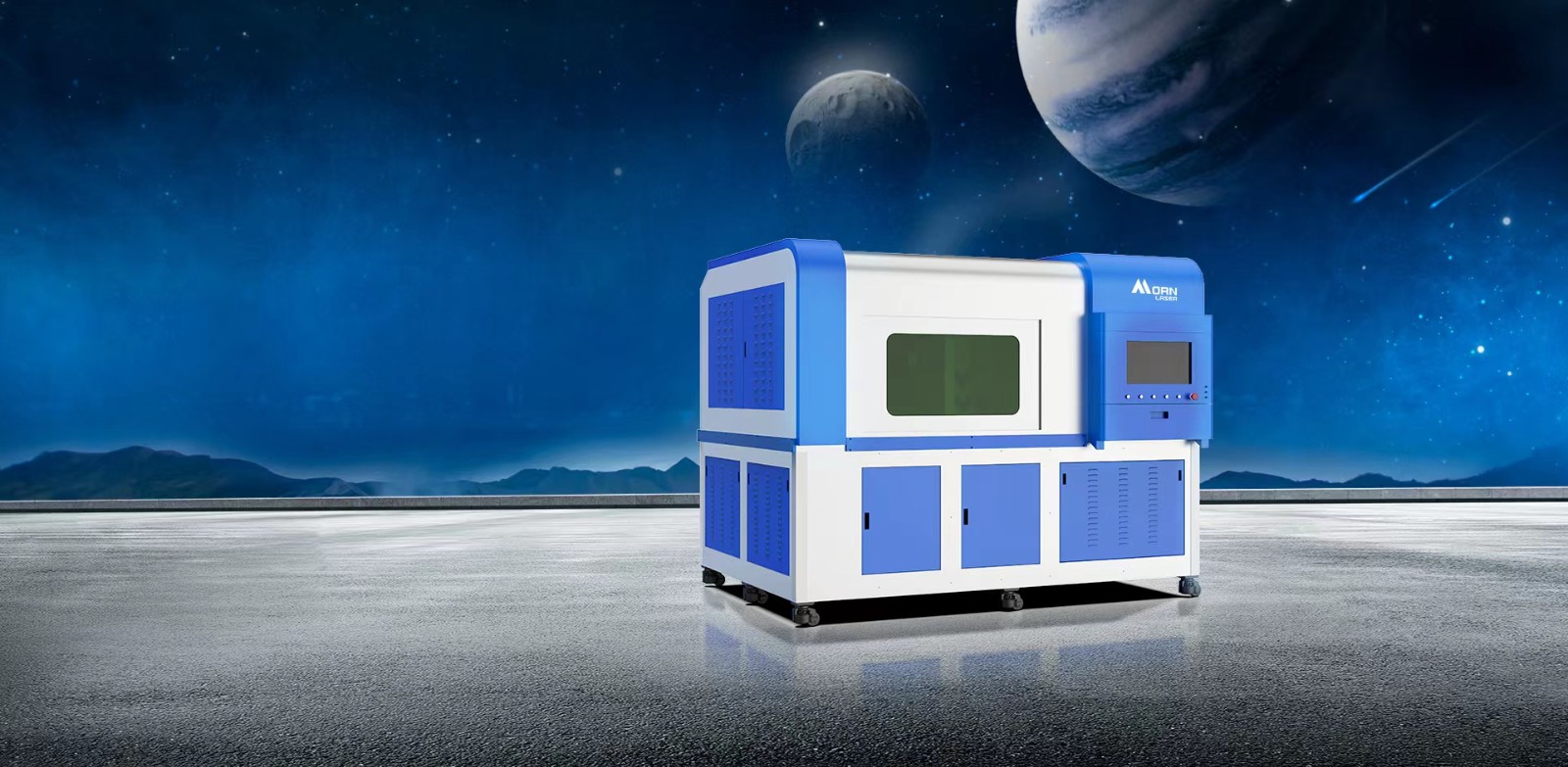

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Common Faults and Solutions for Fiber Laser Cutting Machines

2024-11-13Fiber laser cutting machines are indispensable high-precision equipment in modern manufacturing, widely used for processing metal sheets, pipes, and various other materials. However, even the most advanced equipment can encounter faults. This article will introduce some common faults of fiber laser cutting machines and their solutions, helping users quickly diagnose and resolve issues to ensure the efficient operation of the equipment.

1. Reduced Laser Output Power

Fault Symptoms:

Slower cutting speed and poor cutting results.

Incomplete cutting or uneven edges.

Possible Causes:

Aging or damage to the laser source.

Contamination or damage to optical components.

Cooling system failure leading to overheating of the laser source.

Solutions:

Check the Laser Source: Confirm if the laser source is functioning normally and replace it if necessary.

Clean Optical Components: Use specialized cleaning agents and soft cloths to clean lenses, mirrors, and other optical components.

Inspect the Cooling System: Ensure the water quality and flow rate of the cooling system are normal, and replace the coolant if necessary.

2. Nozzle Blockage

Fault Symptoms:

Nozzle blockage during cutting.

Unstable cutting results with residual material on the edges.

Possible Causes:

Spatter from the cutting material entering the nozzle.

Insufficient or unstable high-pressure gas supply.

Solutions:

Clean the Nozzle: Use compressed air or a soft brush to remove residue from the nozzle.

Check Gas Supply: Ensure the pressure and flow rate of the high-pressure gas are stable, and replace the gas filter if necessary.

3. Machine Movement Abnormalities

Fault Symptoms:

Uneven machine movement and cutting path deviations.

Abnormal sounds or overheating from motors.

Possible Causes:

Wear or rust on guides and screws.

Motor driver failure.

Encoder failure or signal interference.

Solutions:

Inspect Guides and Screws: Clean the guides and screws, apply lubricant, and replace worn parts if necessary.

Check Motor Drivers: Confirm if the motor drivers are functioning normally and replace them if necessary.

Inspect Encoders: Ensure encoders are securely connected and signals are transmitted normally, and replace them if necessary.

4. Control System Failures

Fault Symptoms:

CNC system fails to start or runs unstably.

Black screen or error messages on the display.

Possible Causes:

Software faults or corrupted system files.

Hardware failures, such as the motherboard or memory.

External interference, such as electromagnetic interference.

Solutions:

Restart the System: Try restarting the control system to see if it returns to normal.

Restore the System: Use backup files to restore system settings.

Inspect Hardware: Confirm if hardware connections are secure and replace faulty components if necessary.

Shield Interference: Ensure the equipment is away from strong magnetic fields or other sources of interference.

5. Cooling System Failures

Fault Symptoms:

Cooling system fails to start or water flow is obstructed.

Overheating alarms from the laser source.

Possible Causes:

Failure of the cooling pump.

Clogged or leaking cooling pipes.

Dirty or insufficient coolant.

Solutions:

Check the Pump: Confirm if the cooling pump is functioning normally and replace it if necessary.

Inspect Pipes: Clean or replace cooling pipes to ensure smooth water flow.

Replace Coolant: Regularly replace the coolant to keep the cooling system clean.

Morn Laser: Professional Laser Solutions Provider

Founded in 2008, Morn Laser is a Chinese high-tech enterprise that integrates R&D, production, sales, and service into a comprehensive smart equipment manufacturing company. As a one-stop industrial laser solutions provider, Morn Laser leverages cutting-edge production technology, reliable service, and a commitment to lifetime product responsibility to become the preferred laser brand for tens of thousands of global customers. We continuously strive for technological innovation, dedicated to providing customers with efficient, precise, and environmentally friendly laser cutting solutions.

Conclusion

Although fiber laser cutting machines are advanced, they can still encounter various faults during use. By understanding common faults and their solutions, users can quickly diagnose and resolve issues, ensuring the efficient operation of the equipment. If you have any questions or need further assistance, feel free to contact Morn Laser. We are committed to providing you with the highest quality products and services to help you stand out in a competitive market.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()