-

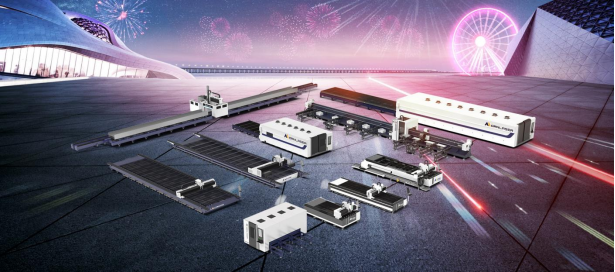

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

How Fiber Laser Cutting Machines are Transforming Manufacturing Processes

2024-11-15In an increasingly competitive global market, manufacturers are constantly seeking ways to optimize their operations, reduce costs, and improve product quality. Fiber laser cutting machines are at the forefront of this transformation, offering exceptional speed, precision, and efficiency. These metal laser cutting machines are not just an upgrade; they are a game-changer for manufacturers across industries. In this article, we will explore how investing in fiber laser cutting technology can give businesses a significant edge in the marketplace.

1. Maximize Operational Efficiency with Faster Production Times

One of the most immediate benefits of fiber laser cutting machines is the dramatic improvement in production speed. Traditional metal cutting methods can be slow and often require additional processes like finishing or polishing to achieve the desired results. Fiber laser cutters, on the other hand, cut materials faster while maintaining high cutting precision, which reduces production time.

2. Reduce Operational Costs

Fiber laser cutting is extremely energy-efficient, consuming far less power than older CO2 laser cutters or mechanical cutting systems. Additionally, fiber laser cutting machines are low-maintenance, reducing repair and servicing costs over time. The minimal wear and tear on parts ensures that your investment lasts longer, offering a better return on investment compared to less durable alternatives.

3. Achieve Higher Profit Margins through Reduced Waste

Manufacturers can achieve tighter tolerances and avoid the errors often associated with traditional mechanical cutting methods, which lead to rework or scrapped materials. This improved material usage translates directly into reduced production costs and higher profit margins.

4. Gain a Competitive Edge

In today’s marketplace, staying ahead of the competition is crucial. Fiber laser cutting machines provide a clear competitive advantage by enabling companies to offer faster lead times, superior product quality, and more cost-effective manufacturing processes. With the ability to achieve higher precision and lower operational costs, businesses can pass these benefits on to their customers, positioning themselves as leaders in the industry. This competitive edge can be the deciding factor in securing long-term contracts, attracting new clients, and expanding market share.

The adoption of fiber laser cutting technology is more than just a trend; it’s a strategic move towards greater efficiency, lower costs, and enhanced product quality. If you’re looking to improve your manufacturing processes and stay ahead of the competition, contact us to learn how our fiber laser cutting solutions can be tailored to meet your unique business needs. Let us help you unlock the full potential of fiber laser technology and drive your success.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()