-

Product

-

Fiber laser cutting machine

-

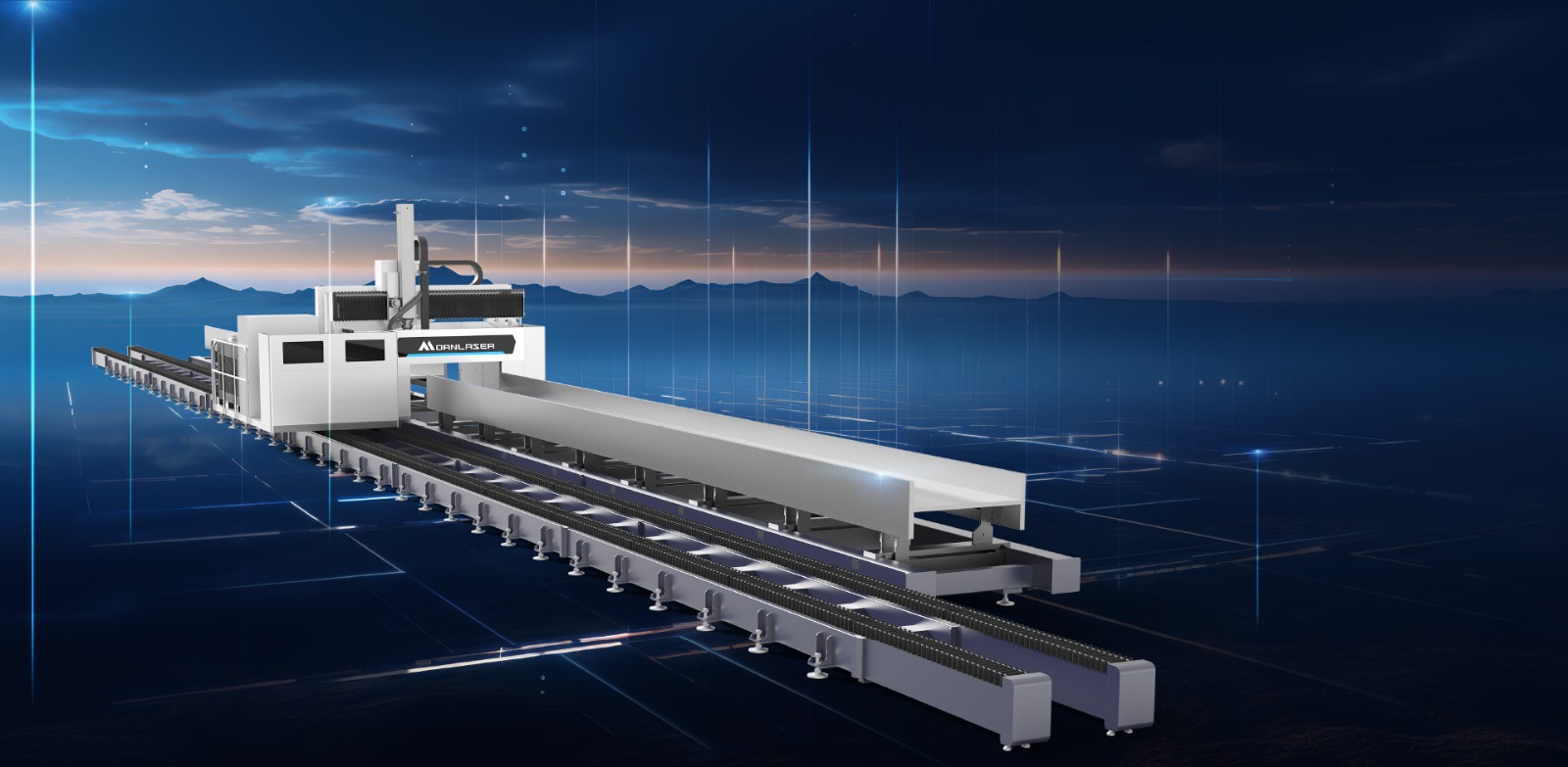

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Why CNC Laser Cutting Is the Best Choice for Your Projects

2024-11-19Why CNC Laser Cutting Is the Best Choice for Your Projects

With the continuous advancement of technology, CNC laser cutting has become the preferred solution for many manufacturing projects. This article will detail why CNC laser cutting is the best choice for your projects, helping you better understand the advantages of this advanced technology.

1. High Precision Cutting

CNC laser cutting technology is renowned for its extremely high precision. Traditional mechanical cutting methods often have inherent errors, especially when dealing with complex shapes and intricate parts. CNC laser cutting can achieve micron-level precision, ensuring that every cut is flawless. This high precision not only enhances product quality but also reduces rework and scrap rates, lowering production costs.

2. Efficient Production Speed

Another significant advantage of CNC laser cutting is its efficient production speed. Compared to traditional cutting methods, laser cutting can perform rapid and continuous cutting operations, significantly increasing production efficiency. Whether for large-scale production or small-batch customization, CNC laser cutting can meet your needs, shorten delivery times, and enhance customer satisfaction.

3. Non-Contact Cutting

CNC laser cutting is a non-contact cutting method, meaning the laser beam does not physically touch the material surface. This characteristic allows laser cutting to avoid causing mechanical stress on the material, thereby reducing the risk of deformation and damage. This is particularly beneficial for thin materials and fragile materials, as non-contact cutting helps maintain their integrity and stability.

4. Versatile Applications

CNC laser cutting technology is suitable for a wide range of materials and applications. Whether it's metal, plastic, wood, or composite materials, laser cutting can handle them all. Additionally, laser cutting can process various complex shapes and patterns, providing designers with greater creative freedom. Whether in automotive manufacturing, electronics, furniture manufacturing, or aerospace, CNC laser cutting plays a crucial role.

5. Low Maintenance Costs and Environmental Friendliness

CNC laser cutting machines typically have low maintenance costs. During operation, there is almost no need to replace cutting tools, reducing repair and replacement costs. Furthermore, the laser cutting process generates minimal waste, aligning with environmental standards and helping businesses achieve sustainable development goals.

Morn Laser: A Leading Laser Solution Provider

Founded in 2008, Morn Laser is a comprehensive intelligent equipment manufacturing high-tech enterprise that integrates R&D, production, sales, and service. As a one-stop industrial laser solution provider, Morn Laser leverages advanced production technology, reliable service, and a commitment to lifelong product responsibility to become the preferred laser brand for tens of thousands of customers worldwide. The primary product is the laser cutting machine, which is widely used in various industries to help clients achieve efficient and precise production.

Conclusion

CNC laser cutting technology, with its high precision, efficient production speed, non-contact cutting, versatile applications, and low maintenance costs and environmental friendliness, is the best choice for modern manufacturing. Whether for large enterprises or small studios, CNC laser cutting can meet your needs and enhance the quality and competitiveness of your products. Choose CNC laser cutting to make your projects stand out.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()