-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

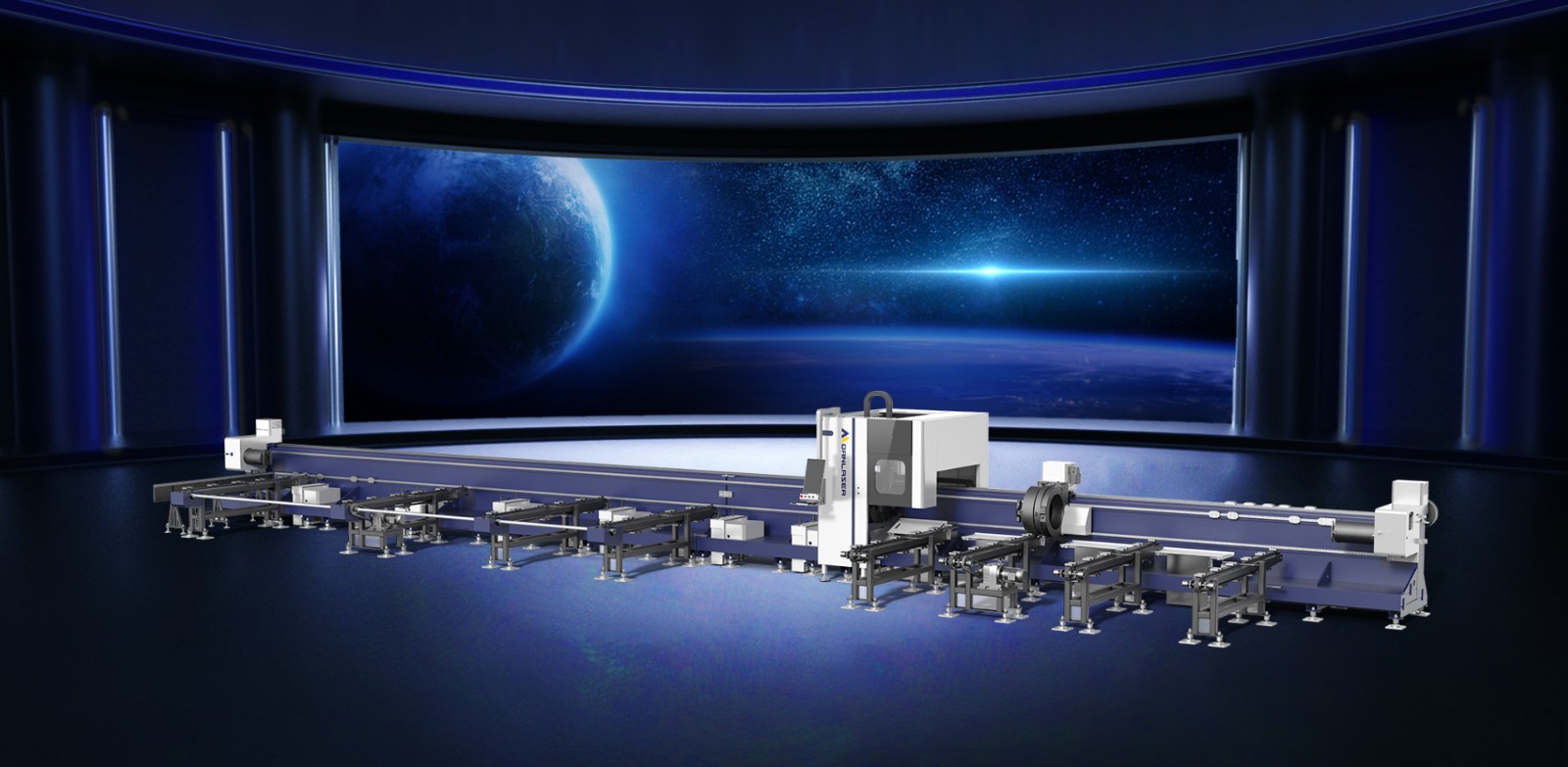

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Common Problems with Fiber Laser Machines and How to Fix Them

2024-11-20Introduction

Fiber laser machines are widely used in industries such as automotive, aerospace, electronics, and medical device manufacturing due to their high precision, efficiency, and versatility. However, like all precision equipment, fiber laser machines can encounter some common issues. This article will discuss these problems and their solutions to help users ensure their equipment remains in optimal condition.

Common Issues and Solutions

Unstable Laser Power

Check if the cooling system is functioning properly, ensuring that the temperature and flow rate of the cooling water meet the requirements.

Clean the laser head and optical components to ensure there is no dust or dirt affecting beam quality.

Calibrate the laser power output to ensure the settings are correct.

Problem Description: Fluctuations in laser power lead to inconsistent processing results.

Solutions:

Slow Cutting Speed

Check if the height of the laser head is appropriate to ensure accurate focus position.

Adjust gas pressure and flow to ensure adequate and stable gas supply.

Optimize cutting parameters, selecting suitable settings based on the material type and thickness.

Problem Description: Cutting speed is significantly lower than expected, impacting production efficiency.

Solutions:

Uneven Cutting Edges

Check if the nozzle is clogged or damaged, and replace it if necessary.

Adjust cutting speed and power to ensure they are well-matched.

Clean the cutting platform to ensure there are no debris affecting cutting performance.

Problem Description: Cutting edges exhibit burrs or unevenness.

Solutions:

Overheating of the Laser Head

Check if the water pathways in the cooling system are clear, ensuring proper circulation of cooling water.

Clean the area around the laser head to remove dust and debris, maintaining good heat dissipation.

Regularly check and replace the coolant to ensure its performance is optimal.

Problem Description: The laser head becomes too hot, potentially leading to damage.

Solutions:

Control System Malfunctions

Restart the control system and try restoring default settings.

Check if the connection cables are loose or damaged, ensuring they are securely connected.

Contact professional technicians for diagnosis and repair.

Problem Description: The control system displays error messages and fails to operate normally.

Solutions:

mornlaser: Your Comprehensive Solution Provider

mornlaser is a high-tech enterprise specializing in R&D, production, sales, and service, providing comprehensive smart manufacturing solutions. As a one-stop industrial laser cutting machine solution provider, we leverage cutting-edge production technology and reliable service to become the preferred laser brand for tens of thousands of customers worldwide. We commit to lifetime responsibility for our products and offer comprehensive technical support and after-sales service.

Conclusion

While fiber laser machines are powerful tools, they can face common issues during use. By promptly identifying and addressing these problems, you can ensure your equipment operates at its best, enhancing production efficiency and product quality. If you need further assistance, please contact mornlaser, and we will be happy to serve you.

This article provides a detailed overview of common issues with fiber laser machines and their solutions, helping users better maintain and utilize their equipment. We hope this information is helpful to you.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()