-

Product

-

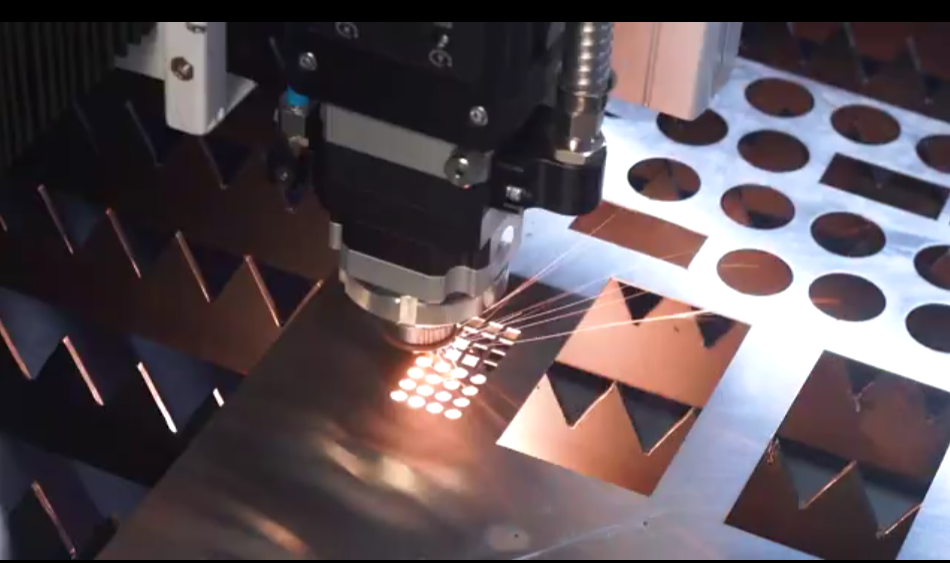

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Do Fiber Laser Machines Save Time and Money?

2024-11-20Introduction

In modern manufacturing, efficiency and cost control are key factors for business success. Fiber laser machines, as advanced laser processing equipment, not only offer high precision and versatility but also significantly save time and reduce costs. This article will explore how fiber laser machines achieve these goals and introduce how mornlaser helps customers maximize their return on investment.

How Fiber Laser Machines Save Time

High-Speed Cutting

Rapid Processing Capability: Fiber laser machines have extremely high cutting speeds, capable of quickly completing various material processing tasks. Compared to traditional laser machines, fiber laser machines can increase cutting speed by over 30%.

Automation Features: Many fiber laser machines come equipped with automation features such as automatic loading and unloading systems and intelligent nesting software, significantly reducing manual intervention and boosting production efficiency.

Precise Control

High-Precision Cutting: Fiber laser machines offer excellent beam quality, achieving micron-level cutting precision and minimizing scrap rates and rework time.

Multi-Task Handling: A single fiber laser machine can process multiple materials and different thicknesses without frequent tool changes or parameter adjustments, saving setup time.

Reduced Setup Time

Quick Setup: Fiber laser machines feature user-friendly interfaces and simple parameter settings, making it easy for even beginners to get started quickly.

Flexible Programming: Advanced programming software allows users to easily create and modify processing programs to meet various production needs.

How Fiber Laser Machines Save Money

Low Energy Consumption

High Energy Efficiency: Fiber laser machines have high electro-optical conversion efficiency, consuming much less energy than traditional laser machines. This means lower operating costs for the same workload.

Long Lifespan of the Light Source: Fiber laser sources have a long lifespan and low maintenance requirements, reducing downtime caused by light source replacements.

Reduced Material Waste

High Material Utilization: The high cutting precision of fiber laser machines maximizes material usage, reducing waste.

Optimized Nesting: Advanced nesting software can automatically optimize material layout, further improving material utilization.

Lower Maintenance Costs

Low-Maintenance Design: Fiber laser machines have a compact structure with fewer moving parts, requiring less maintenance and reducing maintenance costs and downtime.

Remote Diagnostics: Many fiber laser machines support remote diagnostic features, allowing technicians to quickly resolve issues via the internet, reducing the need for on-site service calls.

mornlaser: Your Comprehensive Solution Provider

mornlaser is a high-tech enterprise specializing in R&D, production, sales, and service, providing comprehensive smart manufacturing solutions. As a one-stop industrial laser cutting machine solution provider, we leverage cutting-edge production technology and reliable service to become the preferred laser brand for tens of thousands of customers worldwide. We commit to lifetime responsibility for our products and offer comprehensive technical support and after-sales service.

Conclusion

Fiber laser machines not only significantly improve production efficiency but also effectively reduce operational costs, helping businesses and manufacturers maintain a competitive edge in the market. By choosing mornlaser's fiber laser machines, you can enjoy efficient, reliable, and cost-effective processing solutions, achieving a higher return on investment.

This article provides a detailed exploration of how fiber laser machines save time and money, helping businesses and manufacturers enhance production efficiency and economic benefits. We hope this information is helpful to you.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()