-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

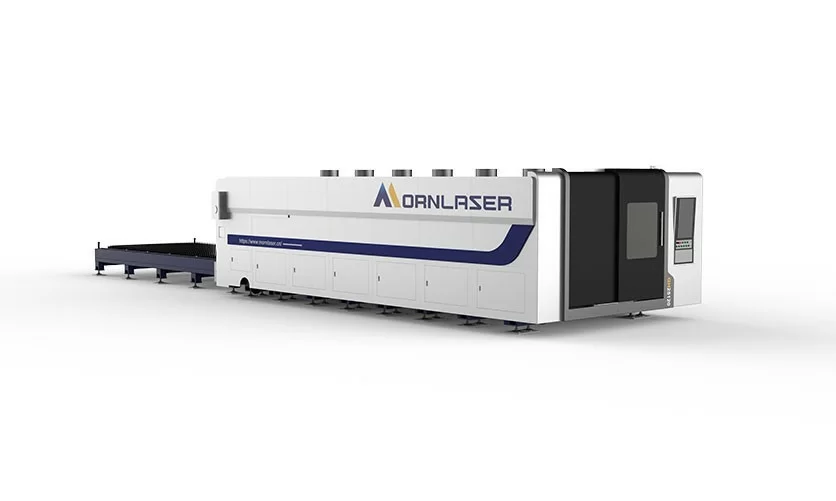

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

What You Need to Know Before Buying a Metal Laser Cutter in 2025

2024-11-21Purchasing a metal laser cutter is a major investment that can significantly impact your manufacturing efficiency, product quality, and long-term profitability. Whether you're running a small workshop or managing a large-scale factory, choosing the right machine requires a clear understanding of your needs and the available technologies. This guide outlines six essential factors to consider before making a decision.

Key Factor 1: Define Your Application Needs

Material Types and Thicknesses

Start by identifying the materials you intend to cut—such as stainless steel, carbon steel, aluminum, or copper—and their respective thickness ranges. Different materials absorb laser energy differently, so selecting the right machine configuration is critical. For example, stainless steel may require higher power and better cooling compared to carbon steel.

Production Volume and Business Scale

Are you a small business handling custom jobs or a factory aiming for mass production? Entry-level fiber laser cutters (1.5–3kW) are ideal for light-duty work, while high-power machines (12kW and above) are better suited for industrial-scale operations with continuous cutting requirements.

Key Factor 2: Understand Technical Specifications

Laser Type

The three main laser types are CO₂, fiber, and YAG. Fiber lasers are currently the most popular in metal processing due to their high cutting speed, energy efficiency, and lower maintenance needs.

Laser Power

Choose laser power according to your typical cutting jobs:

Thin metals (<6mm): 1.5–3kW

Medium thickness (6–20mm): 6–12kW

Thick plates (>20mm): 12–30kW or more

Cutting Speed and Precision

While faster cutting improves productivity, balance it with precision—especially when dealing with fine patterns, tight tolerances, or aesthetic cuts.

Key Factor 3: Consider Automation and Software Capabilities

Automation Features

Modern laser cutters often include features like:

Auto-focusing heads

Auto-loading/unloading systems

Intelligent path optimization

These functions reduce labor costs and maximize cutting efficiency.

Software Support

Ensure the machine supports robust and user-friendly CAM software. Good software can:

Reduce programming time

Improve cutting accuracy

Allow easy integration with other production systems (e.g., ERP, MES)

Key Factor 4: Evaluate Reliability and Maintenance

Brand Reputation

Choose a trusted manufacturer with proven industry experience. Read customer reviews and check local support availability. Brands like Raycus, IPG, and Maxphotonics are known for their performance and service.

Maintenance Costs and Spare Parts

Ask about the maintenance schedule, component lifespan, and availability of spare parts. Simpler designs with modular components typically reduce downtime.

Warranty and Support

Look for:

At least a 1–2 year warranty

Remote technical support

Quick-response on-site service (if applicable)

Key Factor 5: Budget and Return on Investment (ROI)

Initial Investment

Account for the full cost, including:

Equipment price

Installation and setup

Operator training

Operating Costs

Calculate long-term costs like:

Electricity

Consumables (nozzles, lenses, assist gas)

Scheduled maintenance

Energy-efficient machines can drastically lower operating costs over time.

Return on Investment

Estimate how much value the machine will bring:

How much faster can you deliver?

How much labor can you reduce?

Can you expand your product range?

A well-matched machine can pay for itself within 6–24 months in the right setup.

Key Factor 6: Environmental and Safety Considerations

Energy Efficiency and Emissions

Look for machines with eco-friendly designs and certifications. Some machines offer power-saving standby modes or require lower gas consumption.

Safety Features

Ensure compliance with CE, FDA, or local safety standards. Important features include:

Fully enclosed design

Smoke and fume extraction systems

Emergency stop mechanisms

Always train your operators on laser safety protocols.

Conclusion

Choosing the right metal laser cutter in 2025 involves more than comparing specs—it’s about matching the machine to your unique production needs, budget, and long-term goals. By carefully evaluating material types, power levels, automation, software, maintenance, and ROI, you can make a smart investment that pays off for years to come.

Need expert advice or tailored machine recommendations? Contact us today to speak with a laser cutting specialist.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()