-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

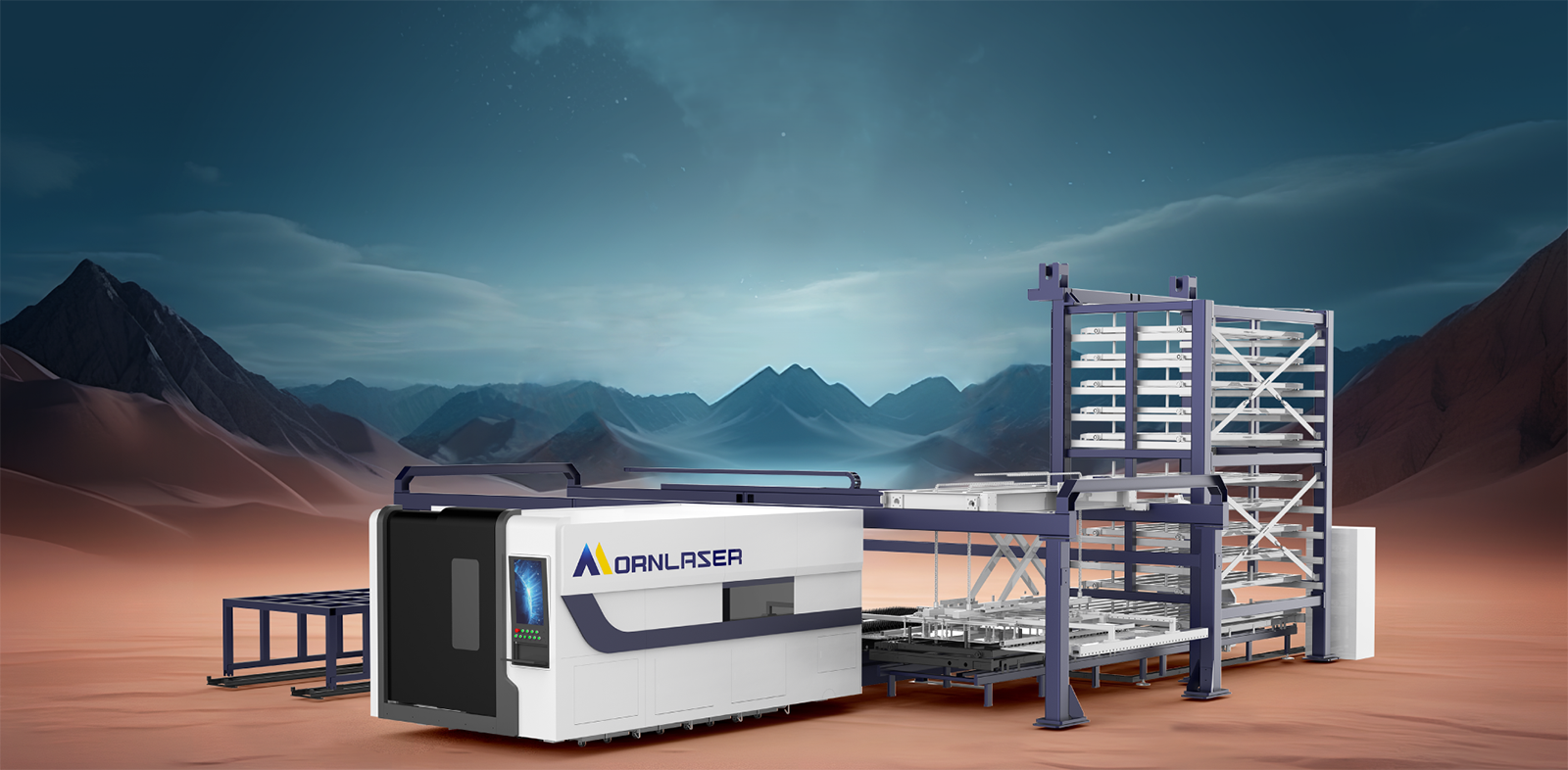

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Coil-fed Automated Laser Cutting Machine: Embracing the Era of Smart Manufacturing

2024-12-23Introduction to Automated Laser Cutting

As Industry 4.0 advances, automated production has become pivotal for the transformation and upgrading of manufacturing. MOrnlaser, a leading Chinese enterprise with 16 years of R&D experience, specializes in laser cutting technology. The company introduces its innovative solution—the coil-fed automated laser cutting machine—ushering in a new era of intelligent manufacturing.

Automatic Loading & Unloading Production Line

MOrnlaser’s coil-fed automated laser cutting machine features an advanced automatic loading and unloading system, streamlining the entire production process. This design ensures rapid, precise material positioning and safe handling, enhancing efficiency while reducing labor costs.

High-performance Specifications for Efficient Production

Maximum Acceleration: 1.5G, ensuring swift responsiveness during direction changes or speed adjustments.

Maximum Linkage Speed: Up to 140 meters per minute, significantly boosting production line efficiency.

Maximum SS Cutting Thickness: Capable of cutting stainless steel up to 100mm thick, meeting diverse industry needs.

Maximum Laser Power: 60,000 watts, providing robust energy output suitable for complex shapes and materials.

Solving Production Challenges

MOrnlaser’s coil-fed automated laser cutting machine offers a comprehensive solution to common issues like material waste, low precision, and inefficiency in traditional cutting processes. It enhances product quality and helps businesses achieve energy-saving and emission reduction goals.

Conclusion

Choosing MOrnlaser’s coil-fed automated laser cutting machine means choosing the path to smart manufacturing. We are committed to offering the most advanced and reliable laser cutting solutions to customers worldwide, helping enterprises enhance competitiveness in today’s dynamic market environment.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()