-

Product

-

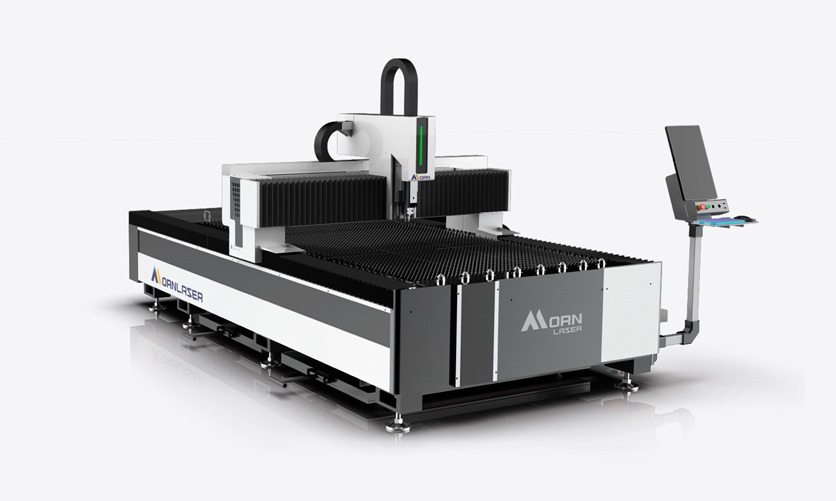

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

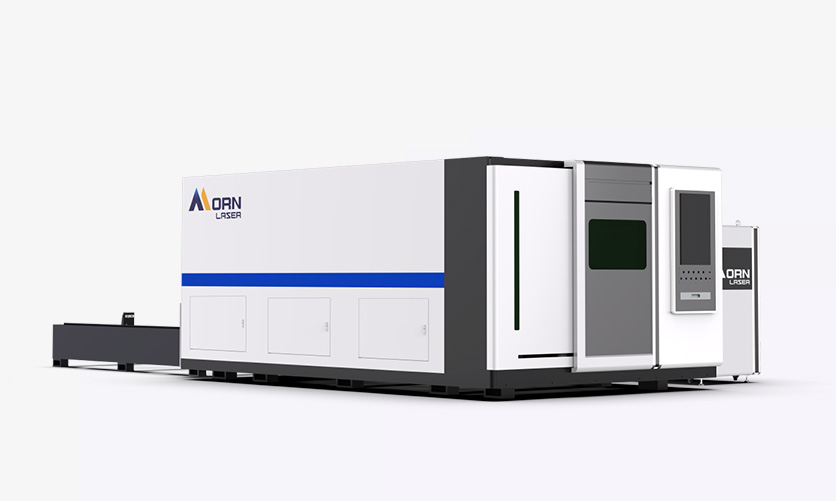

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

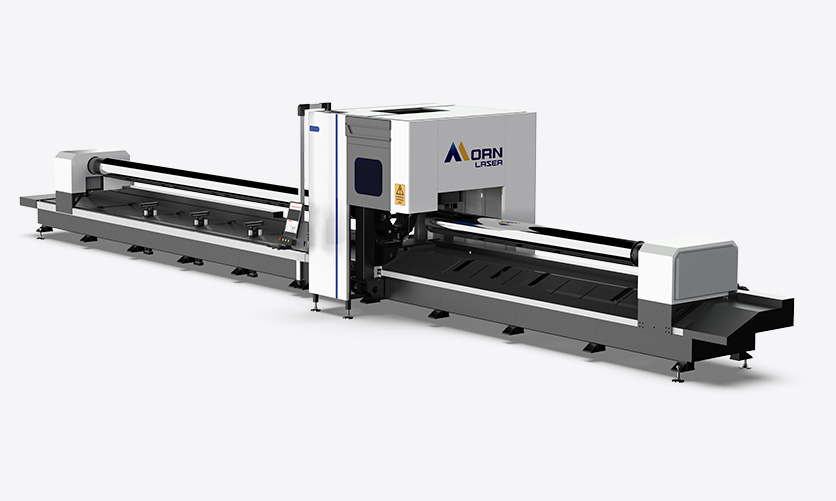

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

How to Start a Fiber Laser Cutting Business?

2022-12-08Fiber laser cutting technology has now developed into a supreme technology in modern laser industry by virtue of its special advantages. Comparing fiber laser cutting with CO2 laser cutting or some other traditional cutting methods, we can find fiber laser cutting technology almost approaches perfection which is shown by its higher precision, delicate quality, faster speed, cleaner work, as well as lower cost of the whole cutting process. And practice will finally prove this.

Fiber laser cutting business is accordingly a hot branch of laser industry and if you are now considering start your business with a fiber laser cutting machine, you do need to prepare and investigate a lot of details. But once you have had a good knowledge about laser cutting, then you have been in the half way of fiber laser cutting business success. To help you learn more about fiber laser cutting machines and choose a best suitable one, the following section will give you an elaborate explanation.

1.Decide which type of metal and product you will process.

Materials and product type are the first priority that you should consider. Fiber laser cutter works best for a wide range of metals, including stainless steel, carbon steel, galvanized sheets, copper plates, aluminum plates and so on. And its application can involve advertising signage, automobile manufacturing, mechanical equipment, electrical equipment, elevator equipment, etc. Although there are so many types of materials and applications to be selected, you should make your own choice before starting a fiber laser cutting business.

2. Try to cut with the machine before buying it.

Many fiber laser cutting machine suppliers allow to make a trial cutting (sample cutting test) before you buy the machine, which can testify whether the machine has the anticipating performance like what the salesman promised. And you will have more confidence on the machine you chose.

3. Operating training and safety rules must be learned.

After you buy a fiber laser cutting machine, it’s time to master how to operate it rightly. Only user manuals from manufacture are far more sufficient to use the machine properly, to which an operating training and safety rule learning are a must. Right and safe operation on the fiber laser cutting machine is the ultimate way to achieve business success.

To start a fiber laser cutting business is not that easy, for there are also additional precautions to be heeded, like warranty, technical support and working lifetime of the machine, market condition and target customers. For more details, we are willing to offer further help about fiber laser cutting machines.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()