-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Main Application Industries of Hand-held Laser Welding Machine

2022-07-28The handheld laser welding machine is characterized by fast welding speed, good effect and beautiful appearance. The advantages are particularly obvious in the welding of sheet metal. The materials that can be welded are: stainless steel, carbon steel, aluminum alloy, galvanized sheet, etc. It can be pure laser welding or wire filler welding. Handheld laser welding machine is easy to learn, quick to use, flexible and convenient, suitable for various welding scenarios.

Today, MORN laser will introduce the main application industries of hand-held laser welding machines:

(Morn laser welding machine show)

1. Automobile manufacturing

In the process of automobile manufacturing, there are many places where laser welding technology is used. Many automobile brands use laser welding as a selling point to attract the attention of many friends. Among them, most of the doors and car covers are metal sheets within 1.2mm, which are suitable for edge welding with a hand-held laser welding machine with better welding strength and more beautiful appearance.

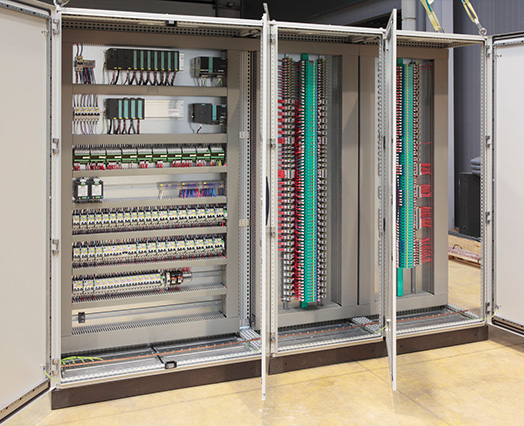

2. Chassis cabinet

In daily life, there are many cabinets and cabinets, such as communication cabinets, electrical cabinets, computer cabinets, water tanks, etc. Most of them are metal sheets within 2mm. The industry is increasingly showing the characteristics of “small batches and multiple varieties”. With the user’s pursuit of the aesthetic appearance of sheet metal, the welding accuracy is required to be higher and higher, and the welding seam is required to be more and more beautiful. The hand-held laser welding machine has increasingly become the choice of many chassis and cabinet manufacturers due to its technical advantages.

Kitchenware industry

Kitchen utensils are used every day in life, such as stainless steel sinks, cabinets, range hoods, etc. Most of them are stainless steel sheets within 2mm. The kitchenware industry has high requirements for appearance and air tightness. The welding process is an important link in the manufacturing process of kitchen utensils. The hand-held laser welding machine has beautiful welds and good sealing performance after welding, which is very popular among users. There are many types of workpieces in the kitchenware industry, and the hand-held laser welding machine is flexible and convenient, which can meet various welding requirements.

4. Door and window guardrail

In modern life, there are more and more stainless steel and aluminum alloy door and window guardrails. Laser-welded door and window guardrails have beautiful welds, firm welding, not easy to deform, and easy to polish. The hand-held laser welding machine is easy to operate and can be operated by ordinary workers. The welding speed is fast, which improves the welding efficiency. It can also be welded outdoors, which is convenient for on-site welding and installation of guardrails.

5. Metal furniture

Metal furniture has gradually emerged in recent years, and lift desks and ergonomic chairs have become hot spots in the industry. The metal furniture designed by the designer comes in a variety of shapes and variations, each with its own characteristics. Therefore, the welding seam structure and welding form that need to be welded are also very diverse. The hand-held laser welding machine can meet the requirements of various welding seam forms by virtue of its flexibility, and it has increasingly become an essential tool for the majority of metal furniture enterprises.

6. Stainless steel products

There are more and more applications of stainless steel decoration and stainless steel products, and various stainless steel advertising words and graphics require laser cutting and welding. Stainless steel products are mainly thin plates, and the pursuit of beautiful welding. Because of the need for outdoor construction and the need for flexible and convenient welding equipment, hand-held laser welding machines are being chosen by more and more users.

If you also want to buy a laser welding machine, our hot-selling model 1500w MT-W1500P fiber laser welding machine is recommended to you! More details, please free to contact us!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()