-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

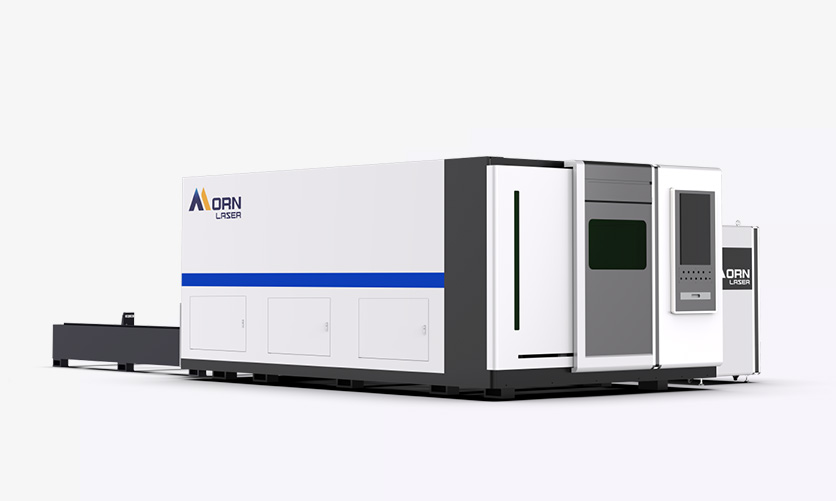

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

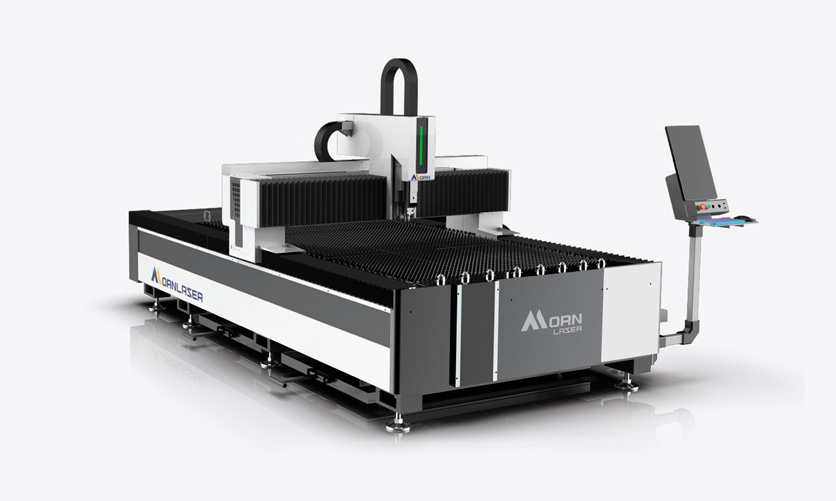

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Fiber Laser Cutting Machine Has Become the “Magic Weapon” of Agricultural Machinery Manufacturing

2024-09-03Fiber laser cutting machine has successfully entered the agricultural machinery industry with the development of the times. Farmers now use all kinds of modern agricultural machinery, such as harvesters, seeders, etc., in the cultivation and harvesting of grain. In recent years, in order to rapidly mechanize agricultural manufacturing, people also puts forward higher cutting requirements for the manufacture of new agricultural machinery products. The laser cutting machine does not require molds, shortens the cycle from development to production, greatly improves the efficiency of agricultural machinery manufacturers, and reduces production costs. So why are laser cutting machines so popular in the agricultural machinery industry? There are two main advantages:

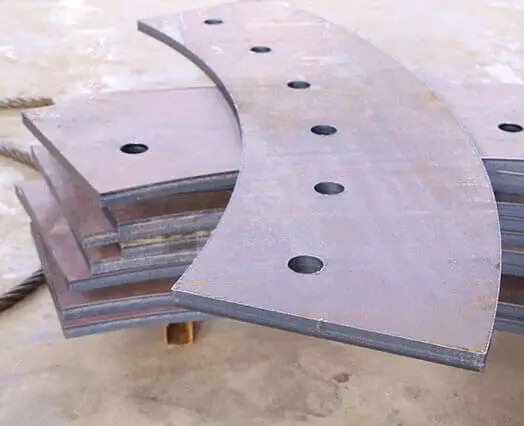

First, the sheet metal processing parts of the agricultural machinery industry generally are 2-6mm, and this thickness is the laser cutting advantageous thickness, not only its cutting speed is faster, but also because of its cutting quality is better and it rarely needs to be secondary processing.

Second,The upgrading of agricultural machinery cannot rely on the traditional cutting process. The traditional cutting method often adopts the punching method, which not only consumes a lot of molds but also wastes the floor space. Generally speaking, the mold storage area of a large agricultural machinery manufacturer is nearly 200 square meters to 300 square meters, which seriously limits the development of agricultural machinery. While the laser cutting machine is different, and it occupies a small area. Usually, the equipment can be put down in a place of 10 to 20 square meters, and the sheet metal parts of the equipment can be cut at any time, which greatly shortens the research&development time and production cycle.

(MORN 6000W Fiber Laser Cutting Machine Working Video)

The above two advantages are the main reason why the laser cutting machine replaces the traditional process, and of course it is also a trend in the modern production demand. In addition, the laser cutting machine has the following advantages:

1. The flexible processing method of laser cutting equipment is good, the cutting speed is fast, and the quality of the cutting is good.

2. High quality laser beam, non-contact processing method, the workpiece will not be deformed and free of burrs.

3. Fully automated production can ensure assembly line operations. The operation of the machine is simpler and more user-friendly, avoiding high-intensity manual labor.

4. The laser cutting machine has high photoelectric conversion rate and high integration, which greatly reduces the production cost.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()